Preparation method of carbon quantum dot and application thereof

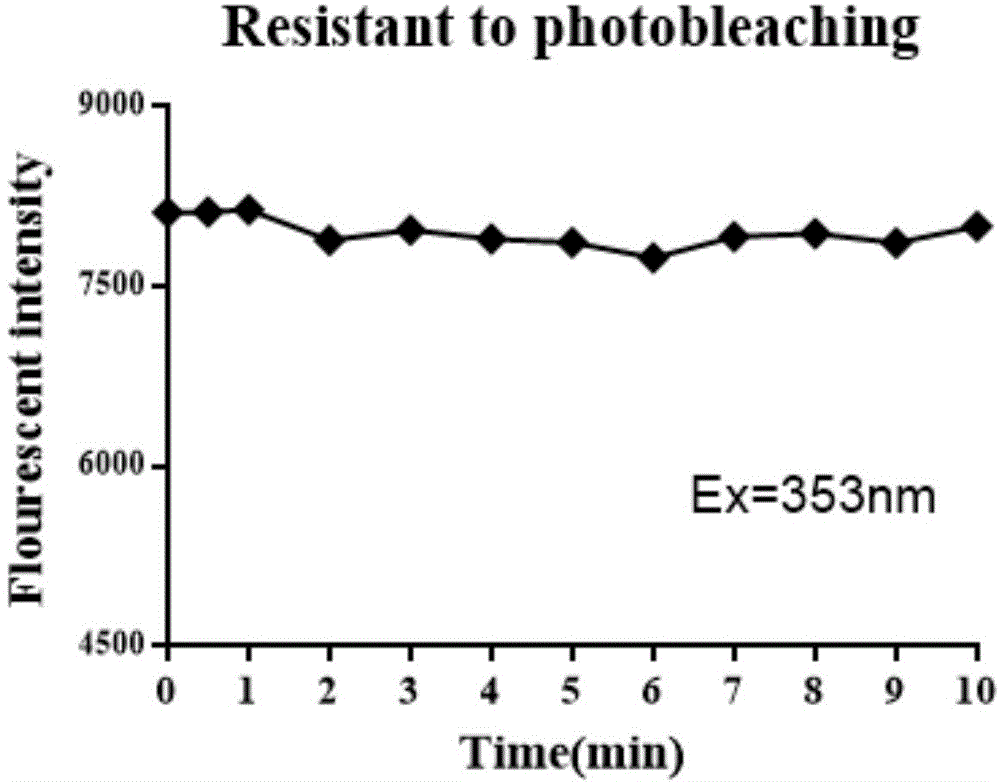

A technology of carbon quantum dots and carbon sources, which is applied in the field of fluorescent quantum dot preparation, can solve problems such as insufficiently high fluorescence quantum yields of carbon quantum dots, cumbersome synthesis methods, and harsh conditions, and achieve good imaging and tracing effects and application prospects. The effect of low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

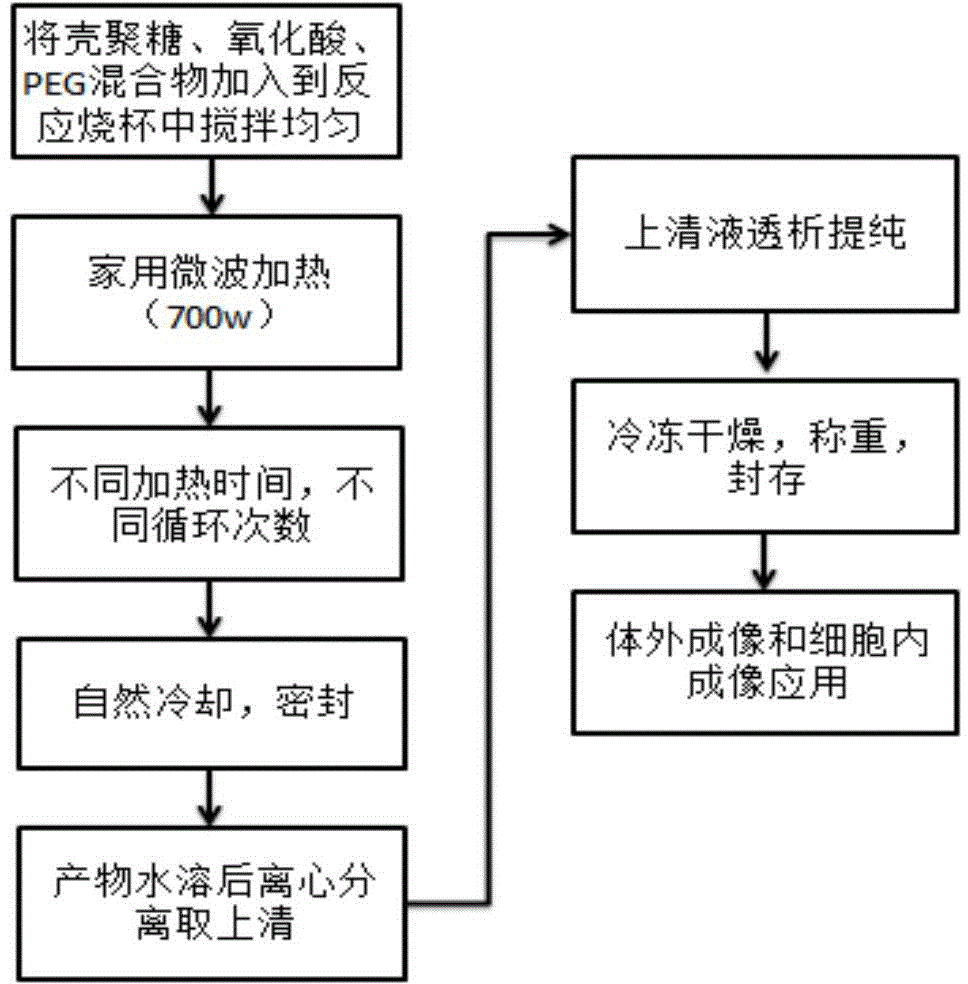

[0019] Embodiment 1: Microwave synthesis of water-soluble chitosan carbon quantum dots

[0020] Step 1. take by weighing the chitosan (100kDa) of 500mg large molecular weight, be dissolved in the acetic acid solution of 250ml acidity 5%; Get 10ml solution and add 5ml concentrated sulfuric acid, stir magnetically, and nitrogen protection 1h;

[0021] Step 2. Put the solution into a high-temperature-resistant beaker, select a 700w power microwave oven, and heat it with microwaves in the mode of 20s ON and 10s OFF, and the number of cycles is 5 times;

[0022] Step 3. Seal the heated product after microwave treatment, cool it down to room temperature naturally, add 5ml of triple distilled water to dissolve the brown product; centrifuge the brown solution at 14000rpm for 10min, and keep the supernatant;

[0023] Step 4. After the supernatant is dialyzed through a dialysis bag, a pure quantum dot C-dots solution is obtained, which is freeze-dried and stored.

Embodiment 2

[0025] Embodiment 2: Microwave synthesis of water-soluble chitosan carbon quantum dots

[0026] Step 1. Weigh 500 mg of chitosan (100 kDa) with a large molecular weight and dissolve it in 250 ml of acetic acid solution with an acidity of 5%; add 5 ml of concentrated sulfuric acid to 10 ml of the solution, stir evenly under magnetic force, and protect with nitrogen for 1 h.

[0027] Step 2. Add 200mg PEG, fully dissolve, add nitrogen protection for a certain period of time, until a uniform solution is produced;

[0028] Step 3. Put the solution into a high-temperature-resistant beaker, select a 900W power microwave oven, and conduct microwave heating in the mode of 20s ON, 10s OFF, and the number of cycles is 10 times;

[0029] Step 4. Seal the heated product after microwave treatment, cool it down to room temperature naturally, add 10ml of triple distilled water to dissolve the brown product; centrifuge the brown solution at 14000rpm for 20min, and keep the supernatant;

[00...

Embodiment 3

[0032] Embodiment 3: Water-soluble carbon quantum surface functional group modification

[0033] Step 1. Freeze-dry the purified carbon quantum dots, weigh 20 mg of C-dots powder, and redissolve it in 0.01M PBS buffer with pH=8.5;

[0034] Step 2. Slowly add 10 mg of succinic anhydride to the solution, stir and mix evenly, and maintain the reaction system pH=8 with 2M NaOH solution throughout the process;

[0035] Step 3. React in the dark at 4°C for 2 hours. After the reaction, dialyze in a PBS solution of 0.01M and pH=8.5 to remove excess succinic anhydride, and maintain the dialysis temperature at 4°C;

[0036] Step 4. Collect the dialyzed solution, centrifuge at 16000rpm for 20min at a high speed, then freeze-dry, weigh and seal for storage.

[0037] Use succinic anhydride to react with the amino group on the surface of C-dots to modify a layer of carboxyl groups on the C-dots, so that the surface charge is reversed, which is conducive to the chemical reaction between car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com