Method for preparing solid briquette fuel from biomass liquefaction residue

A technology for solid molding fuel and liquefaction residue, which can be applied to waste fuel and other directions, can solve the problems that biomass liquefaction residue cannot be effectively treated, the quality of liquefied oil is not high, and the liquefaction efficiency is low. Problems, the effect of low energy consumption for crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

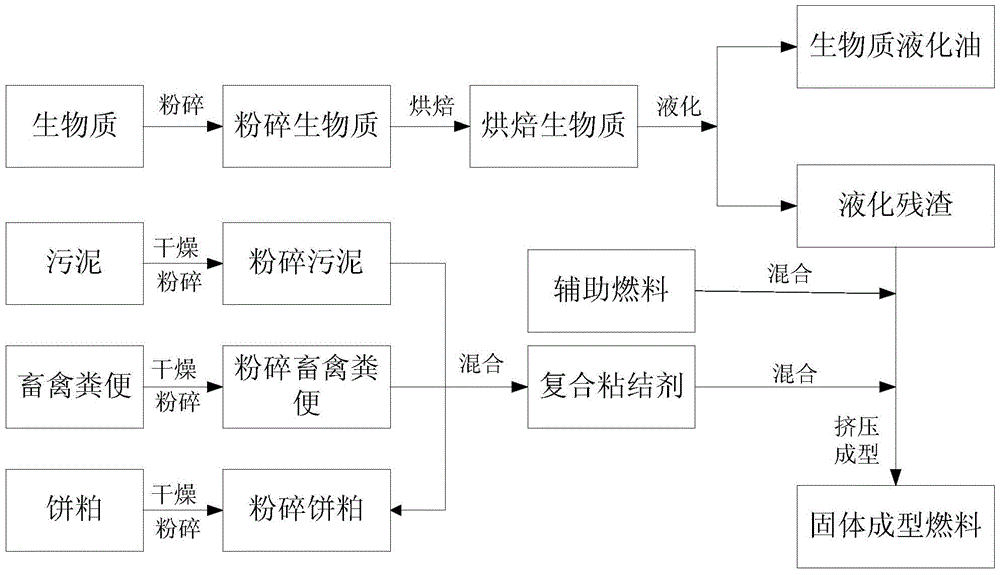

[0032] A method for preparing solid briquette fuel from biomass liquefaction residue of the present invention, the process flow is shown in Figure 1, comprising the following steps:

[0033] (1) Roasting: pulverize the biomass to a length of ≤20 mm, and then roast the obtained pulverized biomass under anoxic conditions to obtain roasted biomass.

[0034] (2) Liquefaction: crush the roasted biomass to a particle size of 40 mesh to 80 mesh, then transport it to a high-pressure closed reactor, add a liquefaction solvent and a catalyst to the reactor, and raise the temperature of the reactor to 200°C to 350°C , pressurize to 5MPa-15MPa, carry out liquefaction reaction in air or inert atmosphere, the reaction time is 20min-80min, after the reaction is completed, biomass liquefaction oil and biomass liquefaction residue are obtained.

[0035] (3) Molding: biomass liquefaction residue (preferably dried biomass liquefaction residue), binder (preferably the binder obtained by mixing th...

Embodiment 2

[0048] A method for preparing solid briquette fuel from biomass liquefaction residue of the present invention comprises the following steps:

[0049] (1) Roasting: crush corn stalk raw materials with a moisture content not higher than 25% to a length of ≤20mm, and roast the crushed corn stalk raw materials in a circulating fluidized bed under nitrogen at a temperature of 200°C. The residence time (i.e. the roasting time, the same description for other embodiments) is 30min to obtain the roasted corn stalk raw material;

[0050] (2) Liquefaction: The roasted corn stalk raw material is further crushed to a particle size of 40-80 meshes, transported to a high-pressure closed reaction kettle under natural air, and after adding ether and potassium hydroxide accounting for 1.5% of the mass of the roasted corn stalk raw material, Raise the temperature of the reactor to 300°C and pressurize to 10MPa. The mass volume ratio of the roasted corn stalks and ether is 1:15g / mL, and keep at t...

Embodiment 3

[0054] A method for preparing solid briquette fuel from biomass liquefaction residue of the present invention comprises the following steps:

[0055] (1) Baking: crush the raw material of Castanopsis pruriens with a moisture content not higher than 25% to a length of less than 20mm, and place the crushed raw material of Castanopsis pruriens in a circulating fluidized bed under an industrial flue gas atmosphere with an oxygen content of less than 5%. Carry out roasting treatment in middle, the roasting temperature is 220 ℃, and residence time is 30min, obtains the raw material of roasted Castanopsis pruriens;

[0056] (2) Liquefaction: further pulverize the raw material of roasted Castanopsis pruriens to a particle size of 40-80 meshes, transport it to a high-pressure closed reaction kettle under an inert gas atmosphere (specifically nitrogen), add acetone and account for the mass of the raw material of roasted Castanopsis pruriens After adding 2% sodium carbonate, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com