Ultralow-concentration ion palladium activation solution and process for chemical nickel-plating on copper surface

An ultra-low concentration, chemical nickel plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of cumbersome process and high cost, and achieve the effect of low ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Use glass fiber boards (PCB glass fiber copper clad laminates) printed with copper wires and copper surfaces of different sizes and spacings to conduct an example test to facilitate the observation of missing plating and overflow plating.

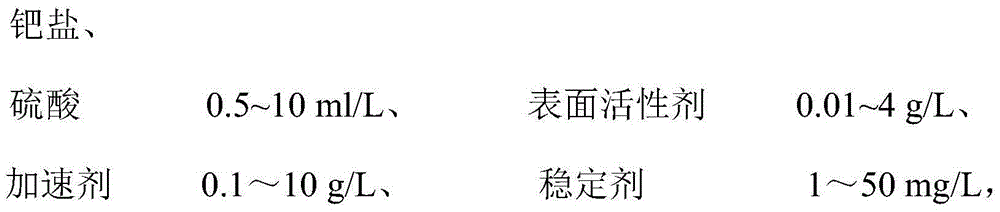

[0029] Activation solution composition:

[0030]

[0031] Operating procedures:

[0032] Plate → Degreasing → Washing → Microetching → Washing → Activation → Washing → Plating.

[0033] The degreasing liquid used is an acidic degreasing liquid, and the conditions of the activation process are controlled: room temperature, no stirring, and a time of 90 s. There is no overflow plating and missing plating phenomenon after nickel plating of the sample.

Embodiment 2

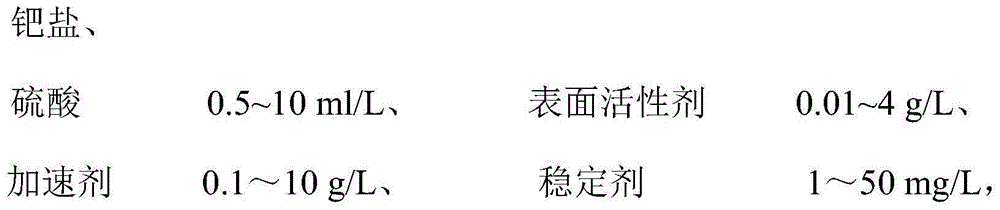

[0035] Activation liquid composition:

[0036]

[0037] Conditional control:

[0038] Room temperature, activation time 2min, stirring method: the test piece moves.

[0039] Operation process is the same as embodiment 1. Nickel plating without overflow plating and missing plating phenomenon

Embodiment 3

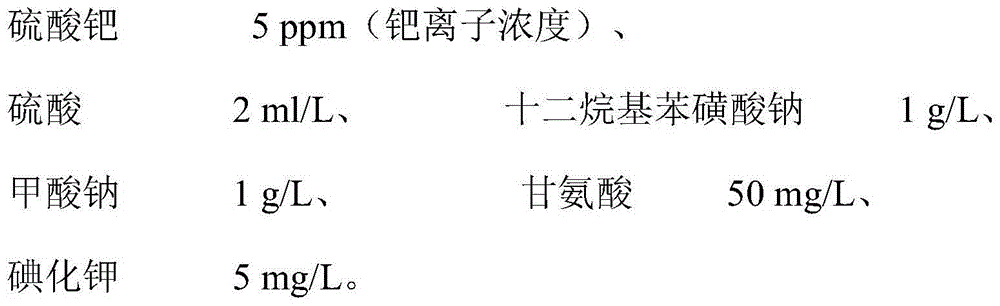

[0041] Activation solution composition:

[0042]

[0043] Conditional control:

[0044] At room temperature, without stirring, activate for 1 min;

[0045] The operation process is the same as that in Example 1, and the nickel plating has no overflow plating and missing plating phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com