System for driving high-temperature electrolysis of CO2/H2O to prepare synthesis gas employing solar energy and application of system

A high-temperature electrolysis and solar energy technology, applied in electrolysis process, electrolysis components, electrodes, etc., can solve problems such as high energy consumption, poor efficiency and selectivity, and difficult electrolytic reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

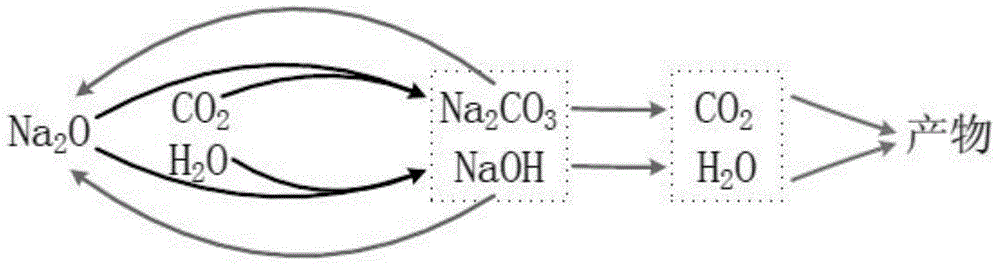

Problems solved by technology

Method used

Image

Examples

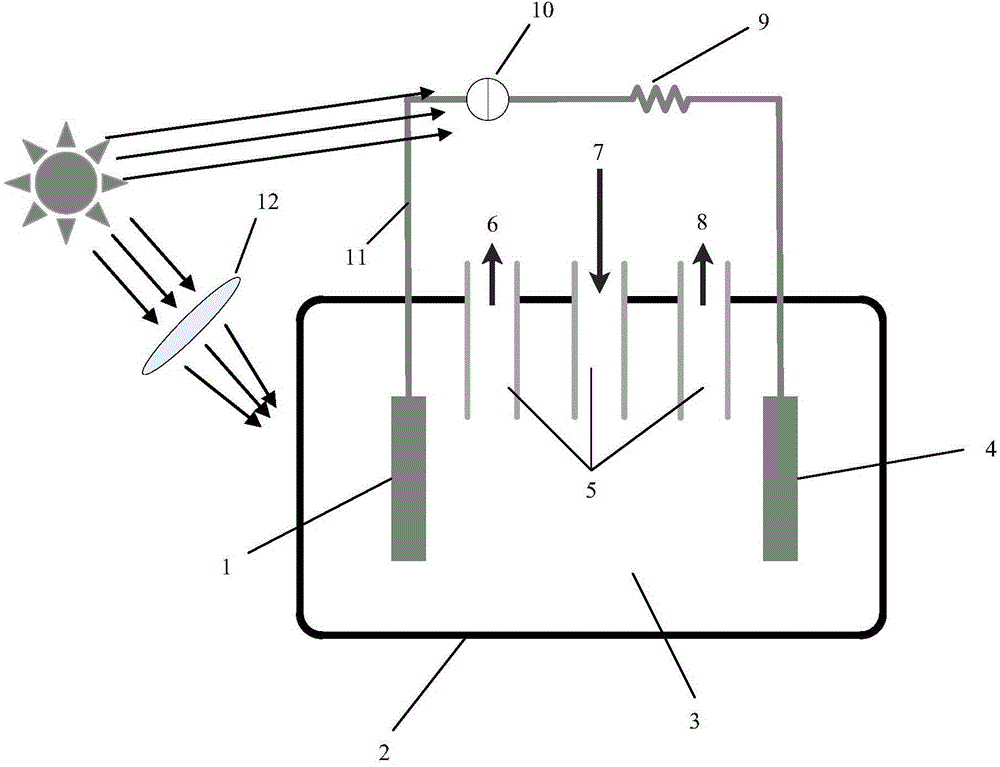

Embodiment 1

[0051] 20g Li respectively 2 CO 3 , 20g Na 2 CO 3 , 20g K 2 CO 3 and 45.09g KOH were ground and pulverized in a mortar and mixed evenly, and transferred into a corundum crucible; respectively, the surface area was 30cm 2 The nickel sheet and iron wire are used as anode and cathode, the reaction is not limited by the size of the electrode area, and the larger the area is beneficial to the reaction; adjust the spot size of the Fresnel lens to keep the temperature constant at 650°C; adjust the rheostat of the solar panel circuit to make the current Constantly 2A. After reacting for 1 hour, the synthesis gas content (volume percentage) in the generated gas is: 89.72% H 2 , 6.857% CO.

Embodiment 2

[0053] 20g Li respectively 2 CO 3 , 20g Na 2 CO 3 , 20g K 2 CO 3 and 51.63g Ba(OH) 2 Grind, pulverize and mix evenly in a mortar, transfer it into a corundum crucible; 2 The nickel-chromium alloy wire and iron wire are used as the anode and cathode; the concentration ratio of the reflective concentrator is adjusted to keep the temperature constant at 750°C; the rheostat of the solar panel circuit is adjusted to keep the current constant at 2A. After reacting for 1 hour, the synthesis gas content (volume percentage) in the generated gas is: 85.67% H 2 , 6.03% CO.

Embodiment 3

[0055] 30g Li respectively 2 CO 3 , 30g Na 2 CO 3 , 30g BaCO 3 , 10.18g LiOH and 33.91g ZnO were ground and pulverized in a mortar and mixed evenly, and then transferred into a high-purity nickel reactor; respectively, the surface area was 15cm 2 The nickel sheet and nickel wire are used as the anode and cathode; the spot size of the Fresnel lens is adjusted to keep the temperature constant at 600°C; the rheostat of the solar panel circuit is adjusted to keep the current constant at 1.5A. After 2 hours of reaction, the synthesis gas content (volume percentage) in the generated gas is: 83.38% H 2 , 5.81% CO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com