Method for preparing chiral poly-fluorene helical nano-fibers

A nanofiber and chiral technology, which is applied in the field of preparing chiral polyfluorene helical nanofibers by solvent chiral transfer method, can solve the problems of complex chiral monomers, complex manufacturing process, limitations, etc., and overcome the high price and overcoming Effects with complex synthesis steps and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Synthesis of 9,9-dioctylfluorene polymer

[0044]

[0045] 2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)-9,9-di-n-octylfluorene (170.70 mg, 0.311 mmol), 2, 7-dibromo-9, 9-di-n-octylfluorene (200 mg, 0.311 mmol), tetrakis (triphenylphosphine) palladium (10.2 mg, 0.00883 mmol), tetrahydrofuran 4.5 mL and 2M Add 3.0 mL of potassium carbonate aqueous solution to the polymerization tube with a stirrer in turn, carry out the Suzuki condensation reaction at 80 °C for 72 h, pour the reactant into 500 mL of methanol / water (10:1, v / v) mixed solvent for precipitation, and suction filter After extraction with acetone and drying in a vacuum oven, the 9,9-dioctylfluorene polymer PF8 was obtained with a yield of 53.5%, a molecular weight of 29880 g / mol, and a molecular weight distribution index of 2.42. By controlling the condensation conditions, 9,9-dioctylfluorene polymers with different molecular weights can be obtained.

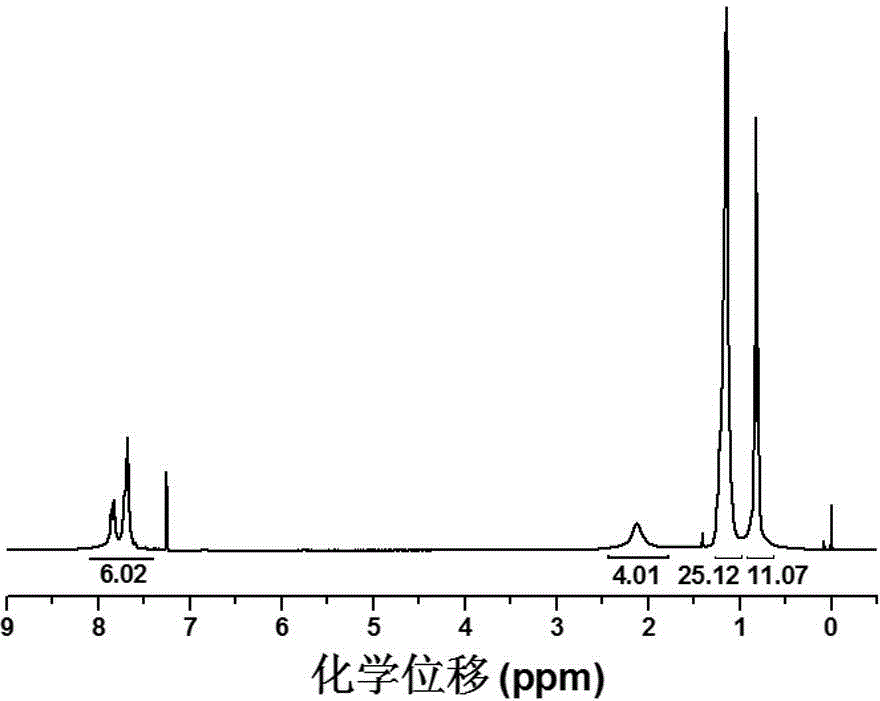

[0046] attached figure 1 For the NMR spectr...

Embodiment 2

[0056] Example 2 Preparation of 9, 9-dioctylfluorene polymer chiral helical nanofibers

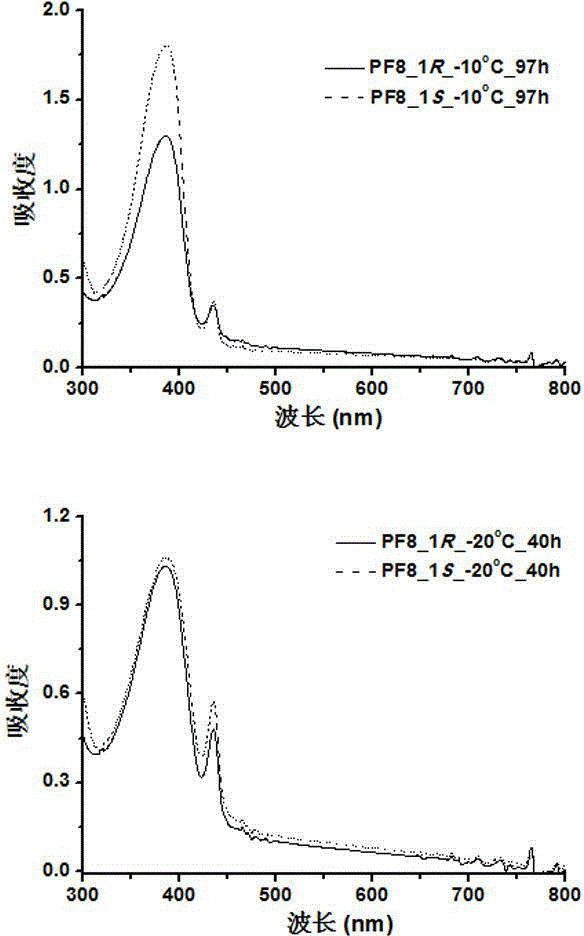

[0057] Take 9,9-dioctylfluorene polymer with a molecular weight of 40000 g / mol: Dissolve 1.0 mg of 9,9-dioctylfluorene polymer in 10 mL ( R )-(+)-limonene solvent to prepare a limonene solution with a concentration of 0.1 mg / mL; heat the prepared solution at 70°C for 4.5h until the solution is completely dissolved, and then return the solution to room temperature; the obtained PF8 / ( R )-(+)-limonene solution was placed at -20℃ for 40 h to self-assemble, and 9, 9-dioctylfluorene polymer chiral helical nanofibers were obtained.

[0058] Dissolve 1.0 mg of 9,9-dioctylfluorene polymer in 2.5 mL ( S )-(-)-limonene solvent and prepared a limonene solution with a concentration of 0.4 mg / mL; heated the prepared solution at 90°C for 3.5 h until the solution was completely dissolved, and then returned the solution to room temperature; the obtained PF8 / ( S )-(-)-limonene solution was then placed at...

Embodiment 3

[0060] Example 3 Preparation of 9, 9-dioctylfluorene polymer chiral helical nanofibers

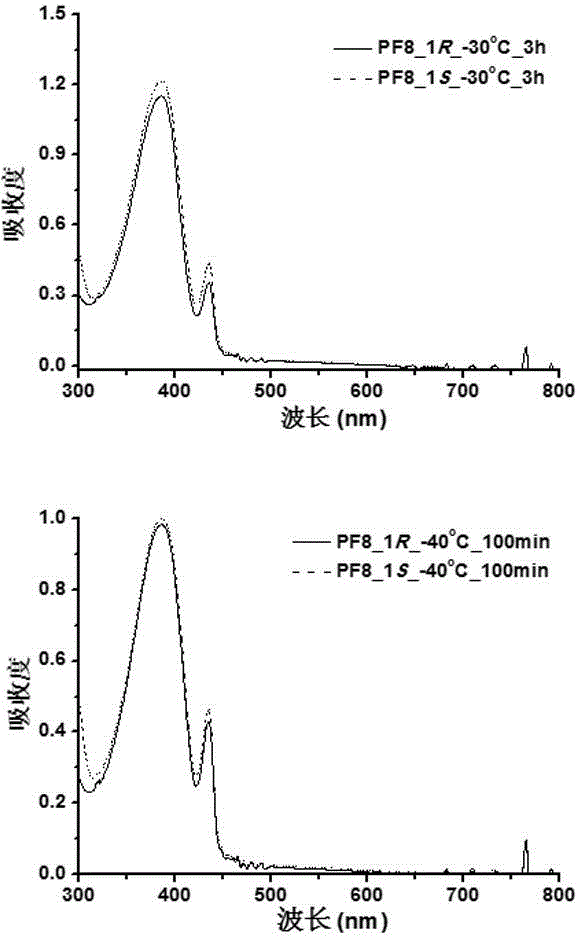

[0061] Take the 9,9-dioctylfluorene polymer of Example 1: Dissolve 1.0 mg of 9,9-dioctylfluorene polymer in 10 mL ( R )-(+)-limonene solvent to prepare a limonene solution with a concentration of 0.1 mg / mL; heat the prepared solution at 80°C for 4 h until the solution is completely dissolved, and then return the solution to room temperature; the obtained PF8 / ( R )-(+)-limonene solution was placed at -40°C for 100 min to self-assemble to obtain 9, 9-dioctylfluorene polymer chiral helical nanofibers.

[0062] Dissolve 1.0 mg of 9,9-dioctylfluorene polymer in 10 mL ( R )-(+)-limonene solvent to prepare a limonene solution with a concentration of 0.1 mg / mL; heat the prepared solution at 80°C for 4 h until the solution is completely dissolved, and then return the solution to room temperature; the obtained PF8 / ( R )-(+)-limonene solution was then placed at -30°C for 3 h to self-assemble, and 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com