A kind of preparation method of safflower essence capsule

The technology of safflower essence and safflower yellow pigment is applied in the field of preparation of safflower essence capsules, which can solve the problems of easy failure in production, storage and use, less extraction of safflower effective components, limiting the efficacy of effective components and the like. , to achieve the effect of improving comprehensive utilization, preventing and treating hyperlipidemia, and delaying oxidative deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

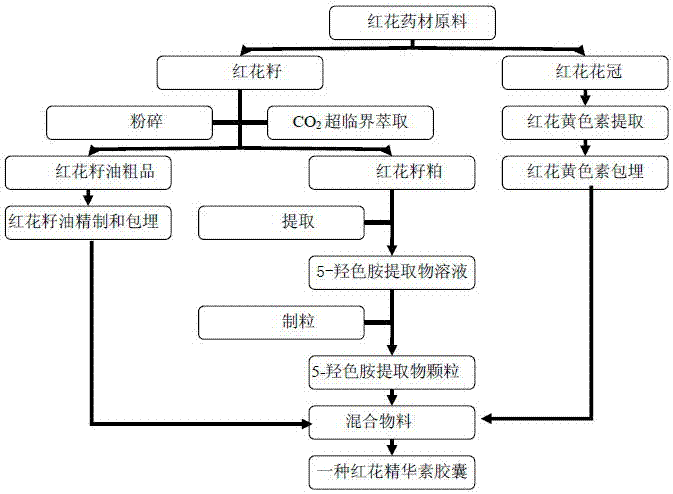

Image

Examples

Embodiment 1

[0027] Embodiments 1 to 3 are specific implementations of a method for preparing safflower essence capsules of the present invention, wherein embodiment 1 is the best embodiment.

[0028] Example 1

[0029] 1) Extraction of safflower yellow pigment: soak for 30-40 minutes according to the ratio of dry material of safflower corolla to water mass ratio of 1:20, then use ultrasonic extractor to perform ultrasonic extraction for 3 times, extraction temperature is 60-62°C, extraction time is 43-46 minutes , to obtain the extract by filtration; pass the extract through HPD-826 macroporous adsorption resin at a loading flow rate of 3BV / h, after the adsorption is completed, let the extract stand for 2 hours, and elute with distilled water at a flow rate of 6BV / h until the Molish reaction is Negative; then elute with 50% ethanol solution by volume at a flow rate of 6BV / h, collect the eluate, and concentrate the eluate under reduced pressure at 50°C to a density of 1.08g / cm 3 , vacuum ...

Embodiment 2

[0036] 1) Extraction of safflower yellow pigment: Soak for 40 minutes according to the mass ratio of safflower corolla dry material to water 1:19, then use an ultrasonic extractor to perform ultrasonic extraction twice, extraction temperature is 62°C, extraction time is 43 minutes, and the extract is obtained by filtration; Pass the extract through HPD-826 macroporous adsorption resin at a loading flow rate of 3BV / h. After the adsorption is complete, let the extract stand for 3 hours, and elute with distilled water at a flow rate of 6.5BV / h until the Molish reaction is negative; The percentage concentration of 50% ethanol solution was eluted at a flow rate of 6.5BV / h, the eluate was collected, and the eluate was concentrated under reduced pressure at 50°C to a density of 1g / cm 3 , vacuum drying or freeze-drying at 45°C to obtain solid safflower yellow;

[0037] 2) Embedding of safflower yellow: weigh solid safflower yellow and β-cyclodextrin at a mass ratio of 1:7, and mix β-c...

Embodiment 3

[0043] 1) Extraction of safflower yellow pigment: Soak for 35 minutes according to the ratio of dry material of safflower corolla to water mass ratio of 1:21, then use an ultrasonic extractor to perform ultrasonic extraction for 3 times, the extraction temperature is 61°C, the extraction time is 46 minutes, and the extract is obtained by filtration; Pass the extract through HPD-826 macroporous adsorption resin at a loading flow rate of 3BV / h. After the adsorption is completed, let the extract stand for 2~3h, and elute with distilled water at a flow rate of 6BV / h until the Molish reaction is negative; then use The ethanol solution with a concentration of 50% by volume was eluted at a flow rate of 6BV / h, the eluate was collected, and the eluate was concentrated under reduced pressure at 50°C to a density of 1.04g / cm 3 , vacuum drying or freeze-drying at 45°C to obtain solid safflower yellow;

[0044] 2) Embedding of safflower yellow pigment: Weigh the solid safflower yellow pigm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com