Catalyst system for olefin polymerization reaction

An olefin polymerization and catalyst technology, applied in the field of olefin polymerization catalyst systems, can solve problems such as different polymer properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

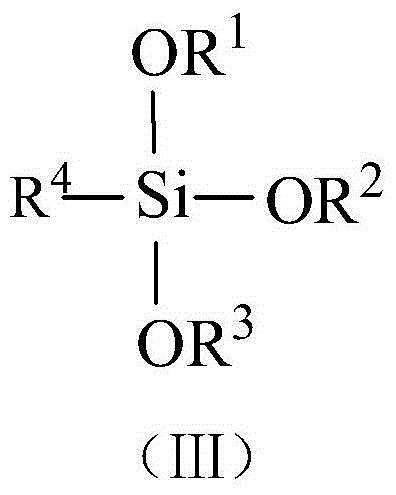

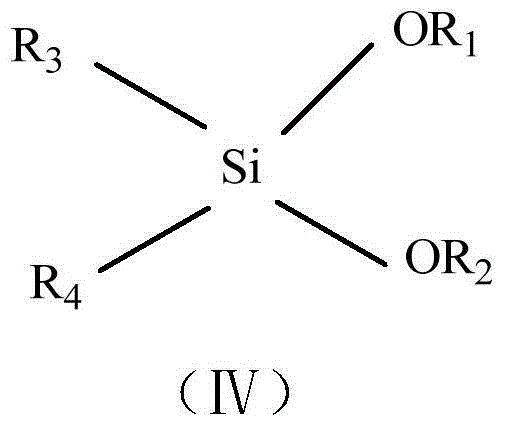

Method used

Image

Examples

Embodiment 1

[0047] 1A, preparation of titanium-containing spherical solid catalyst component A

[0048] Add 100ml of titanium tetrachloride to a 300ml stirring glass reaction bottle fully replaced by high-purity nitrogen, cool to -20°C, add spherical magnesium chloride alcoholate (see Chinese patent CN1330086A for the preparation method), and slowly raise the temperature in stages To 110°C, add 3.9mmol of diisobutyl phthalate during the heating process, and after keeping the temperature at 110°C for 0.5h, filter off the liquid, add titanium tetrachloride to treat twice, then wash with hexane five times, vacuum After drying, titanium-containing solid catalyst component A (main catalyst) was obtained.

[0049] 1B, propylene polymerization

[0050] In a 5-liter autoclave, use a nitrogen stream to purge at 70°C for 1 hour, then replace the polymerization vessel 3 times with gas-phase propylene, and introduce 5 ml of a hexane solution of triethylaluminum (triethylaluminum) under nitrogen prot...

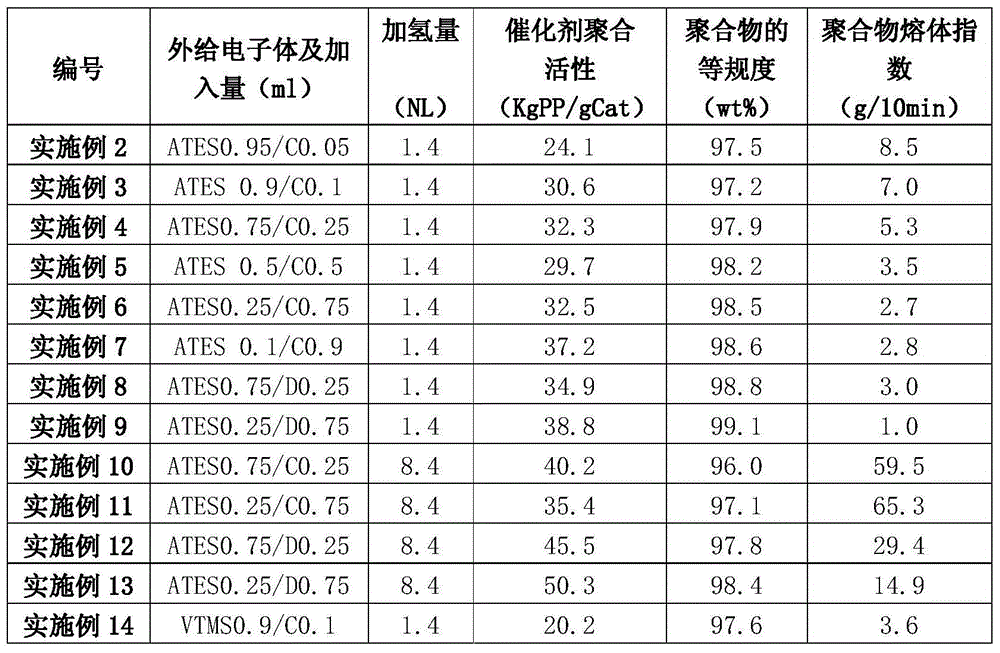

Embodiment 2~27

[0052] The solid catalyst prepared in 1A of Example 1 was polymerized according to the method of propylene polymerization in 1B of Example 1, with different amounts of hydrogenation and different additions of external electron donors. The composite external electron donor added during polymerization is a hexane solution of alkene-based trihydrocarbyloxysilane and hydrocarbyl dihydrocarbyloxysilane. The polymerization and test results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com