Nail-free glue and preparation method thereof

A technology of nail-free glue and formula, which is applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve problems affecting construction operations, high internal stress of glue, and strong odor, etc., and achieve good application and promotion prospects. The effect of wide base material and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

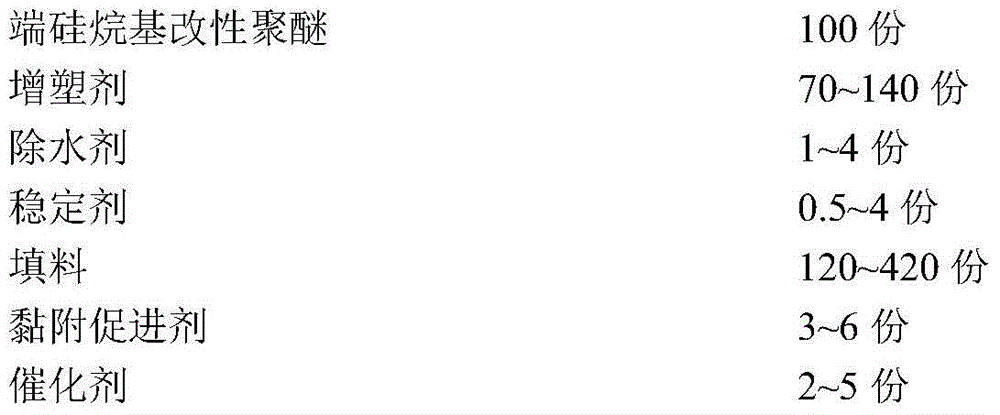

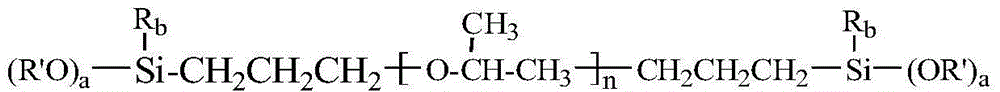

Method used

Image

Examples

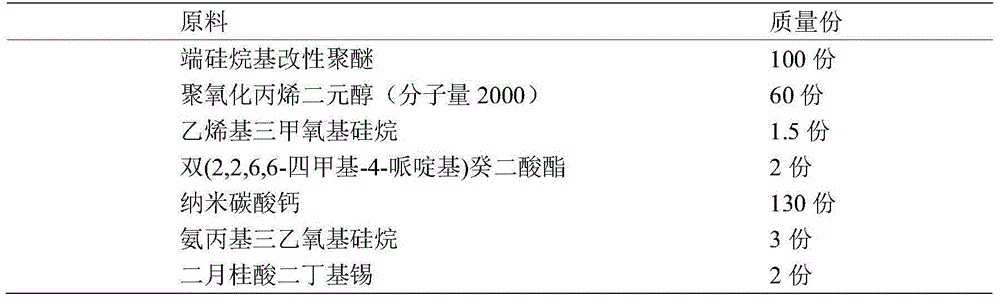

Embodiment 1

[0038] Place the nano-calcium carbonate in a constant temperature oven and dry at 120°C for 20 hours; 100 parts of silyl-terminated polyether, 80 parts of polyoxypropylene diol, bis(2,2,6,6-tetramethyl- Add 2 parts of 4-piperidinyl) sebacate into the planetary kneader, then vacuumize, continue stirring and degassing for 20 minutes; stop stirring and vacuuming, add 60 and 70 parts of nano-calcium carbonate fillers in batches, and mix well Vacuum at 100-110°C to 0.090±0.005MPa, stir and degas for 1-2 hours; reduce the temperature of the obtained high-mixture to below 50°C, fill with nitrogen, add 1.5 parts of vinyltrimethoxysilane, adhesion promotion Agent aminopropyltriethoxysilane 3 parts, mix well. Add 2 parts of catalyst dibutyltin dilaurate under the condition of nitrogen protection, and mix evenly; vacuumize, continue to mix evenly; fill with nitrogen to release the vacuum to normal pressure, and discharge the material into sub-packages to obtain nail-free glue.

[0039] ...

Embodiment 2

[0042] The preparation method of this sealant is as in Example 1.

[0043] Raw material composition and mass parts in the embodiment 2 of table 2

[0044]

Embodiment 3

[0046] The preparation method of this sealant is as in Example 1.

[0047] Raw material composition and mass parts in the embodiment 3 of table 3

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com