Compression-resistant cutting fluid

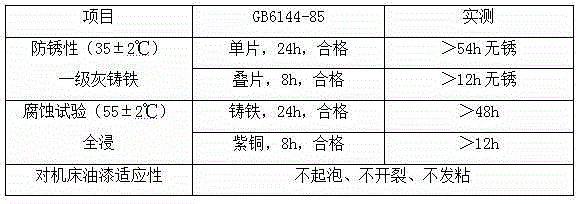

A cutting fluid and raw material technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of precipitation or stratification, oil separation, poor bacterial resistance, poor anti-rust effect, etc., and achieve good anti-rust ability and low cost , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of anti-pressure cutting fluid is characterized in that it is made up of the raw material of following weight part:

[0020] Chlorinated paraffin 4, lithium hydroxide 0.5, hexahydrophthalic anhydride 0.8, triethanolamine oleic acid soap 0.7, camphor oil 1-2, zinc naphthenate 0.5, sodium diacetate 0.8, calcium ricinoleate 1, 6-tert-butyl o-cresol 0.6, bisphenyltriazole alcohol 1, allylthiourea 0.4, oleic acid 2, dicyclohexylamine carbonate 0.4, mineral oil 5, deionized water 80, rare earth functional additive 7;

[0021] Described rare earth functional additive is made up of the following raw materials of weight part:

[0022] Lanthanum sulfate 3, octoxynol 2, sodium alkylbenzene sulfonate 2, divinylbenzene 0.2, alkenyl succinate 4, trimethylolpropane 0.7, lanolin 3, nano silicon dioxide 1-2 , deionized water 200, polyethylene glycol 400014;

[0023] Mix polyethylene glycol 4000 and lanolin into the reactor, heat and melt, adjust the temperature of the reactor t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com