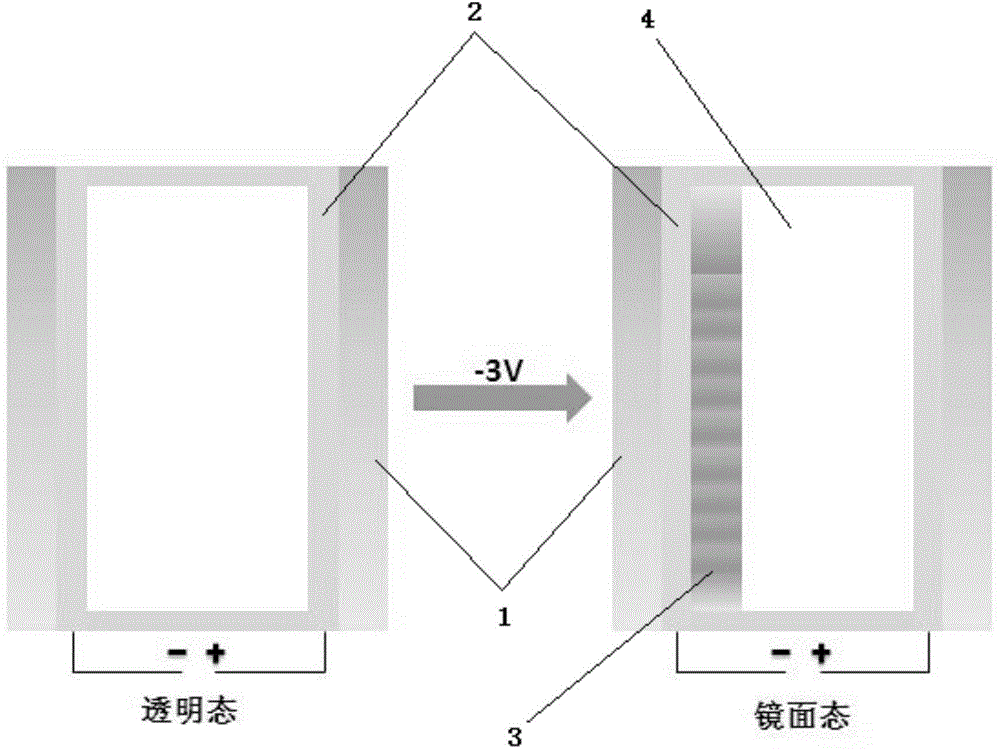

Method for preparing flexible adhesive electrochromic device capable of being switched between mirror state and transparent state

An electrochromic device and mutual conversion technology, which can be used in instruments, nonlinear optics, optics, etc., can solve the problems of complex preparation, high cost, fragile electrochromic smart windows, etc., and achieve a simple preparation method, easy operation, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific Embodiment 1: In this embodiment, the preparation method of the flexible and stickable electrochromic device that can be transformed between the mirror state and the transparent state is carried out according to the following steps:

[0023] 1. Cut the ITO / PET film according to the needs, and then ultrasonically clean it in acetone, methanol and ultrapure water, each cleaning time is 10-20 minutes, and then dry it with nitrogen to obtain a flexible substrate;

[0024] 2. Add calcium hydride to dimethyl sulfoxide, heat and reflux for 6-8 hours, and distill under reduced pressure under nitrogen to obtain dry dimethyl sulfoxide, which is sealed and stored under nitrogen protection;

[0025] 3. Dissolve silver nitrate, cupric chloride and tetra-n-butylammonium bromide in the dry dimethyl sulfoxide obtained in step 2 to prepare an electrolyte. The concentration of silver nitrate in the electrolyte is 10-100mM, and copper chloride The concentration of tetra-n-butylam...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mass fraction of calcium hydride in dimethyl sulfoxide in step 2 is 0.4% to 1%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: the dimethyl sulfoxide obtained after drying under reduced pressure is put into molecular sieves for sealed storage. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com