Preparation method of spherical hollow lithium titanate/graphene composite material as lithium battery negative material

A technology of empty lithium titanate and graphene, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of decreased specific capacity, low ionic conductivity, low conductivity of lithium titanate, etc., to improve electrical conductivity, The effect of improving specific capacity and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the examples.

[0030] Example 1

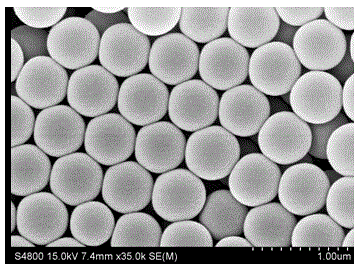

[0031] (1) Preparation of silica spheres:

[0032] Dissolve 1.6 mL of tetraethyl orthosilicate (TEOS) in 44 mL of absolute ethanol to form solution A; dissolve 10 mL of ammonia water in 44 mL of absolute ethanol to form solution B; dissolve 2 mL of tetraethyl orthosilicate Dissolve in 88 mL of absolute ethanol to form C solution.

[0033] Add solution A and solution B into the three-necked flask, and start stirring at the same time. After reacting for 30 minutes, add 8 mL of ammonia water into the three-necked flask, and after reacting for 5-10 minutes, add solution C to the system, and continue the reaction for 2 minutes. h, performing repeated centrifugation and washing with water to obtain a solid phase, that is, silica spheres.

[0034] (2) Preparation of ...

Embodiment 2

[0042] (1) Preparation of silica spheres:

[0043] Dissolve 1.6 mL of tetraethyl orthosilicate (TEOS) in 44 mL of absolute ethanol to form solution A; dissolve 10 mL of ammonia water in 44 mL of absolute ethanol to form solution B; dissolve 2 mL of tetraethyl orthosilicate Dissolve in 88 mL of absolute ethanol to form C solution.

[0044] Add solution A and solution B into the three-necked flask, and start stirring at the same time. After reacting for 30 minutes, add 8 mL of ammonia water into the three-necked flask, and after reacting for 5-10 minutes, add solution C to the system, and continue the reaction for 2 minutes. h, performing repeated centrifugation and washing with water to obtain a solid phase, that is, silica spheres.

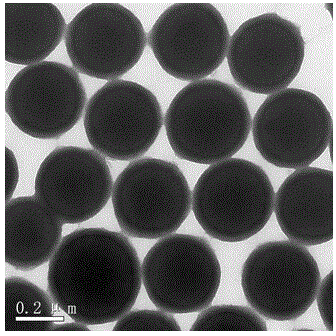

[0045] (2) Preparation of silica titania:

[0046]Mix 0.1 g of hydroxypropyl cellulose, 60 mL of absolute ethanol and 0.6 mL of deionized water to form a mixed solution.

[0047] Take 0.2 g of silica spheres and ultrasonically disperse them ...

Embodiment 3

[0053] (1) Preparation of silica spheres:

[0054] Dissolve 1.6 mL of tetraethyl orthosilicate (TEOS) in 44 mL of absolute ethanol to form solution A; dissolve 10 mL of ammonia water in 44 mL of absolute ethanol to form solution B; dissolve 2 mL of tetraethyl orthosilicate Dissolve in 88 mL of absolute ethanol to form C solution.

[0055] Add solution A and solution B into the three-necked flask, and start stirring at the same time. After reacting for 30 minutes, add 8 mL of ammonia water into the three-necked flask, and after reacting for 5-10 minutes, add solution C to the system, and continue the reaction for 2 minutes. h, performing repeated centrifugation and washing with water to obtain a solid phase, that is, silica spheres.

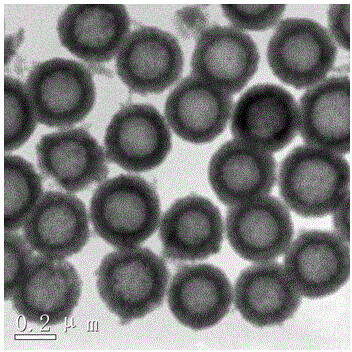

[0056] (2) Preparation of silica titania:

[0057] Mix 0.1 g of hydroxypropyl cellulose, 60 mL of absolute ethanol and 0.6 mL of deionized water to form a mixed solution.

[0058] 0.2 g of silica spheres were ultrasonically dispersed in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com