Breast injection medicament for resisting cow mastitis and preparation method thereof

A mastitis and breast technology, applied in the direction of anti-inflammatory agents, antibacterial drugs, pharmaceutical formulas, etc., can solve the problems of low cure rate of dairy cow mammary gland diseases, residual time of drugs, and affecting milk quality, etc., to reduce body weight The effect of increasing the number of cells, less residue, and improving the cure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

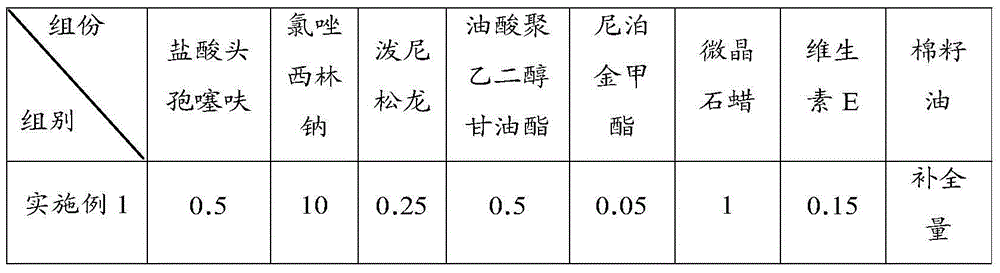

[0033] In this example, the specific dosage of the raw materials for producing 100 ml of the udder injection agent for cow mastitis is prepared according to the following table 1. The specific preparation method is: heating 30-35% of the total amount of cottonseed oil, and then the oil Acid macrogol glyceride, methyl paraben, microcrystalline paraffin and vitamin E are added to cottonseed oil and stirred evenly until they are completely dissolved to form the first mixture, and then the three major ingredients ceftiofur hydrochloride, cloxacillin sodium, prednisolone and 10-20% of the total amount of cottonseed oil are mixed and stirred evenly to form the second mixture, then the first mixture and the second mixture are mixed and stirred evenly, then the remaining cottonseed oil is added and emulsified for a period of time After cooling, subpackage, each 10ml.

[0034] Table 1 raw material consumption

[0035] Unit: g

[0036]

[0037] The udder injection medicament of thi...

Embodiment 2

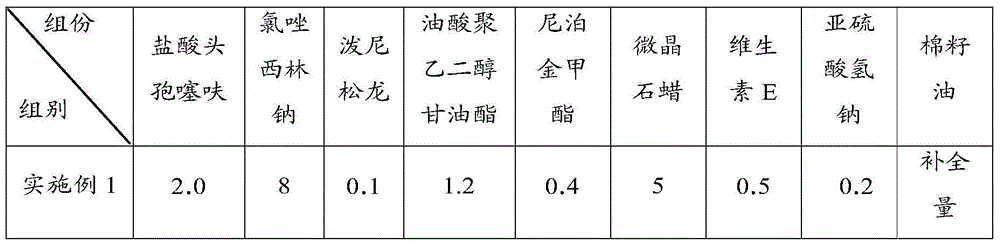

[0042] In this example, the specific amount of raw materials for the udder injection of 100 ml of dairy cow mastitis is formulated according to the following table 2. The specific preparation method is: 30-35% of the total amount of cottonseed oil is mixed at 60-70 ° C. Under heating, then these additives of macrogol glycerol oleate, methylparaben, microcrystalline paraffin, vitamin E and sodium bisulfite are added to the cottonseed oil at a rate of 200-300rad / min Stir evenly until the first mixture is completely dissolved, then mix and stir 10-20% of the three major ingredients ceftiofur hydrochloride, cloxacillin sodium, prednisolone and the total amount of cottonseed oil to form the second mixture, and then Mix the first mixture and the second mixture at a speed of 200-300rad / min, then add the remaining cottonseed oil, stir for 30 minutes with a shear emulsifier, then cool and distribute, each 10ml.

[0043] Table 2 raw material consumption

[0044] Unit: g

[0045]

...

Embodiment 3

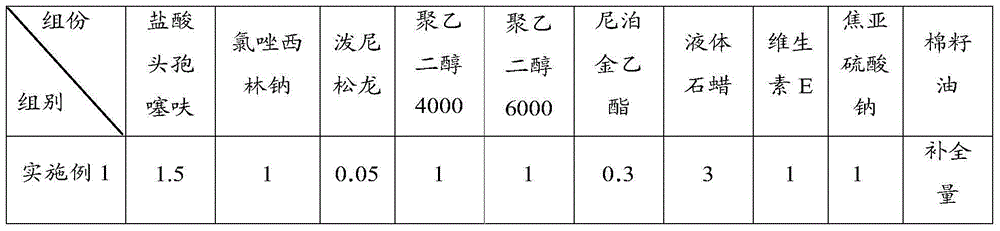

[0048] In this example, the specific dosage of the raw materials for every 100ml of milk cow mastitis injection medicine produced is formulated according to the following table 3. The specific preparation method is: 30-35% of the total amount of cottonseed oil is mixed at 60-70°C Under heating, then several additives such as polyethylene glycol 4000, polyethylene glycol 6000, ethyl paraben, liquid paraffin, vitamin E and sodium metabisulfite are added to the cottonseed oil at a rate of 200-300rad / min Stir evenly until the first mixture is completely dissolved, then mix and stir 10-20% of the three major ingredients ceftiofur hydrochloride, cloxacillin sodium, prednisolone and the total amount of cottonseed oil to form the second mixture, and then Mix the first mixture and the second mixture at a speed of 200-300rad / min, then add the remaining cottonseed oil, stir for 30 minutes with a shear emulsifier, then cool and distribute, each 10ml.

[0049] Table 3 raw material consumpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com