A kind of plant type formaldehyde scavenger and preparation method

A formaldehyde scavenger, plant-based technology, applied in the field of plant-based formaldehyde scavenger and preparation, can solve problems such as affecting health, secondary pollution of ammonia gas, inability to remove formaldehyde, etc., achieving long action time, increasing reaction speed, reducing The effect of reaction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

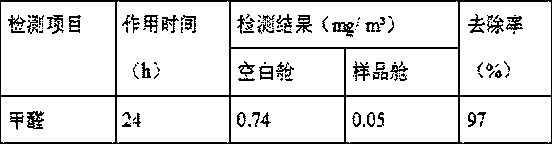

Image

Examples

Embodiment 1

[0011] The plant-type formaldehyde scavenger is composed of the following materials: in parts by weight, 10 parts of ethylene urea, 8 parts of chlorogenic acid, 2 parts of glycine, 1 part of menthol, 1 part of anthocyanin, 2 parts of citric acid, 2 parts of osmotic acid Agent JFC, 1.5 parts of triethanolamine, 3 parts of tartaric acid, 2 parts of sodium chloride, 10 parts of ethanol, 150 parts of deionized water.

[0012] Its preparation method comprises the following steps:

[0013] 1. Place 1 part of menthol and 10 parts of ethanol in the first reactor, heat to 35-45 ° and stir to generate an intermediate solution;

[0014] 2. Put 10 parts of ethylene urea, 8 parts of chlorogenic acid, 2 parts of glycine, 2 parts of penetrant JFC, 1.5 parts of triethanolamine, 3 parts of tartaric acid, 2 parts of sodium chloride and 150 parts of deionized water in the second reactor , stirring at a temperature of 25-30°;

[0015] 3. After the components of the second reactor are completely...

Embodiment 2

[0017] The plant-type long-acting formaldehyde scavenger consists of the following materials: in parts by weight, 13 parts of ethylene urea, 10 parts of chlorogenic acid, 4 parts of glycine, 2 parts of menthol, 2 parts of anthocyanins, 4 parts of citric acid, 4 parts of Parts of penetrant JFC, 2 parts of triethanolamine, 4 parts of tartaric acid, 4 parts of sodium chloride, 12 parts of ethanol, 180 parts of deionized water. The preparation method and usage method are the same as in Example 1.

Embodiment 3

[0019] The plant-type formaldehyde scavenger is composed of the following substances: in parts by weight, 15 parts of ethylene urea, 9 parts of chlorogenic acid, 5 parts of glycine, 0.5 part of menthol, 0.5 part of anthocyanin, 5 parts of citric acid, and penetrant JFC3 0.5 parts of triethanolamine, 2 parts of tartaric acid, 3 parts of sodium chloride, 11 parts of ethanol, and 160 parts of deionized water. The preparation method and usage method are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com