Method for preparing 1,3-diglyceride through enzymolysis

A technology of diglyceride and enzymatic hydrolysis, which is applied in 1 field, can solve the problems of difficult large-scale production by direct esterification method, low purity of 1,3-DAG, complicated purification process, etc., so as to improve the 2-position selection tendency, The effect of cheap reaction raw materials and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

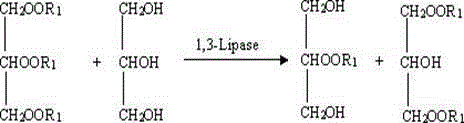

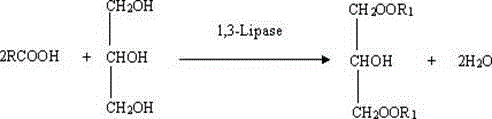

Method used

Image

Examples

Embodiment 1

[0047]1. Mix 1000g soybean oil with 100g water, add 100g ethanol; homogenize at a high speed of 5000rpm for 20min to prepare an emulsion;

[0048] 2. Heat the emulsion to 70°C and keep it at a constant temperature, and adjust the pH of the emulsion to 7.0 with hydrochloric acid or sodium hydroxide;

[0049] 3. Add 20g of Candida antarctica lipase A;

[0050] 4. After 22 hours of reaction, the reaction ends;

[0051] 5. The reaction system was centrifuged, and the oil phase was molecularly distilled to separate monoglyceride and NEFA, diglyceride and triglyceride; the proportion of 1,3-diglyceride in the diglyceride phase was 83%.

Embodiment 2

[0053] 1. Mix 1000g soybean oil with 100g water, add 0.98g gluconic acid; homogenize at a speed of 5000rpm for 20min at high speed to prepare an emulsion;

[0054] 2. Heat the emulsion to 70°C and keep it at a constant temperature, and adjust the pH of the emulsion to 7.0 with sodium hydroxide or hydrochloric acid;

[0055] 3. Add 20g of Candida antarctica lipase A;

[0056] 4. After 19 hours of reaction, the reaction ends;

[0057] 5. The reaction system was centrifuged, and the oil phase was molecularly distilled to separate monoglyceride and NEFA, diglyceride and triglyceride; the proportion of 1,3-diglyceride in the diglyceride phase was 79%.

Embodiment 3

[0059] 1. Mix 1000g soybean oil with 100g water, add 100g ethanol and 0.98g gluconic acid; homogenize at a speed of 5000rpm for 20min at high speed to prepare an emulsion;

[0060] 2. Heat the emulsion to 70°C and keep it at a constant temperature, and adjust the pH of the emulsion to 7.0 with sodium hydroxide or hydrochloric acid;

[0061] 3. Add 20g of Candida antarctica lipase A;

[0062] 4. After 17 hours of reaction, the reaction ends;

[0063] 5. The reaction system was centrifuged, and the oil phase was molecularly distilled to separate monoglyceride and NEFA, diglyceride and triglyceride; the proportion of 1,3-diglyceride in the diglyceride phase was 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com