A kind of spinning solution with hemostatic function and preparation method thereof

A spinning liquid and functional technology, applied in the spinning field, can solve the problems of difficult control of oxidation degree, environmental pollution, and volatile solvent, and achieve good hemostatic performance, low price, and good wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

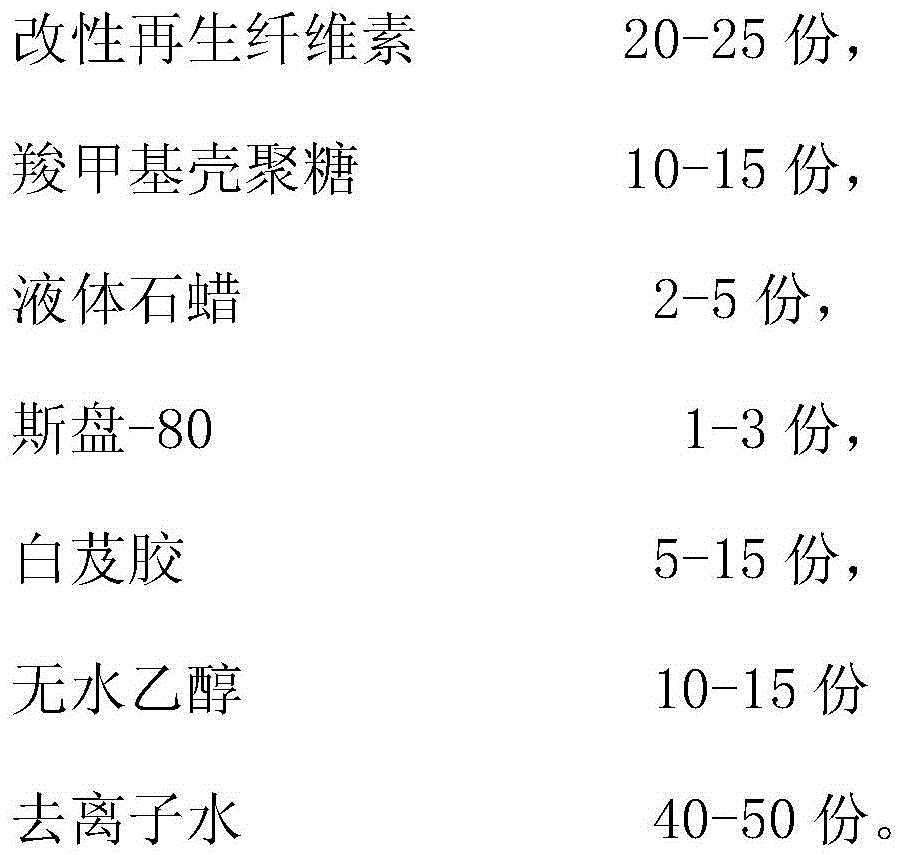

[0028] A spinning solution with hemostatic function, in parts by weight, comprising the following components:

[0029]

[0030] Its preparation method comprises the following steps:

[0031] (1) Mix and stir 4 parts of sodium stearate, 2 parts of acetic acid and deionized water evenly, add 20 parts of regenerated cellulose fiber knitted fabric, continue stirring, add ammonia water to adjust the pH to 10, ultrasonicate for 2 hours at 400W power, add excess Ethanol, obtain mixed dispersion liquid;

[0032] (2) Transfer the mixed dispersion obtained in step (1) to an autoclave, and react at 80°C for 30 minutes. After the reaction, cool the mixed dispersion to room temperature, filter, and wash with absolute ethanol until neutral to obtain modified regeneration cellulose;

[0033] (3) Mix and stir 2 parts of liquid paraffin, 1 part of Span-80 and deionized water evenly, ultrasonicate for 20 minutes at a power of 300W, continue to add modified regenerated cellulose, 10 parts o...

Embodiment 2

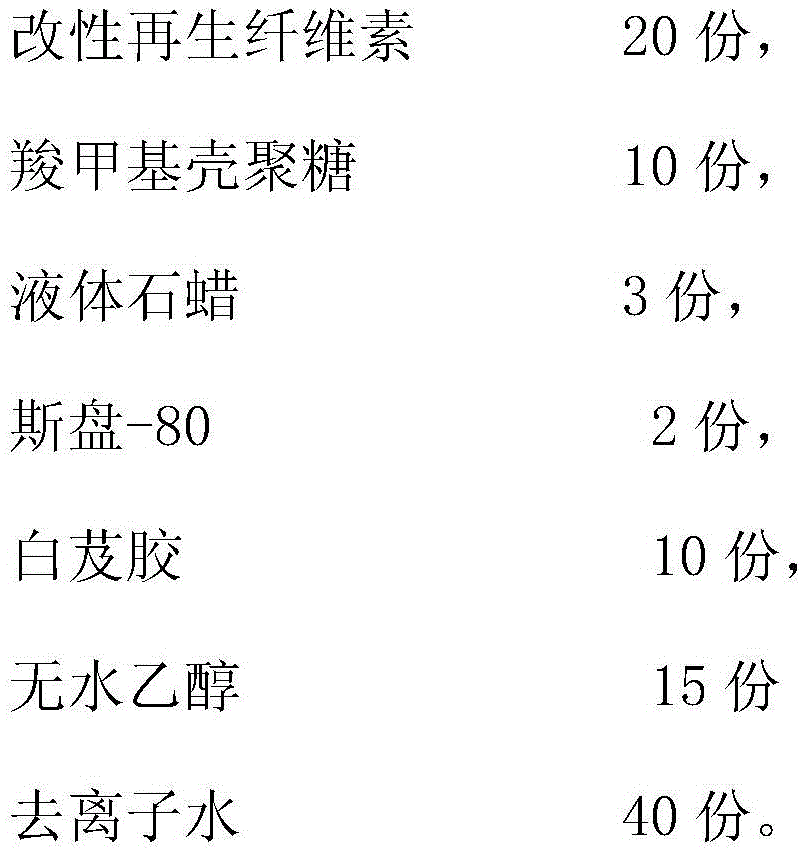

[0035] A spinning solution with hemostatic function, in parts by weight, comprising the following components:

[0036]

[0037] Its preparation method comprises the following steps:

[0038] (1) Mix and stir 6 parts of sodium stearate, 3 parts of acetic acid and deionized water evenly, add 25 parts of regenerated cellulose fiber knitted fabric, continue stirring, add ammonia water to adjust the pH to 11, ultrasonicate for 3 hours at 400W power, add excess Ethanol, obtain mixed dispersion liquid;

[0039] (2) Transfer the mixed dispersion obtained in step (1) to an autoclave, and react at 100°C for 120 minutes. After the reaction, cool the mixed dispersion to room temperature, filter, and wash with absolute ethanol until neutral to obtain modified regeneration cellulose;

[0040] (3) Mix and stir 5 parts of liquid paraffin, 3 parts of Span-80 and deionized water evenly, ultrasonicate for 30 minutes at a power of 500W, continue to add modified regenerated cellulose, 15 part...

Embodiment 3

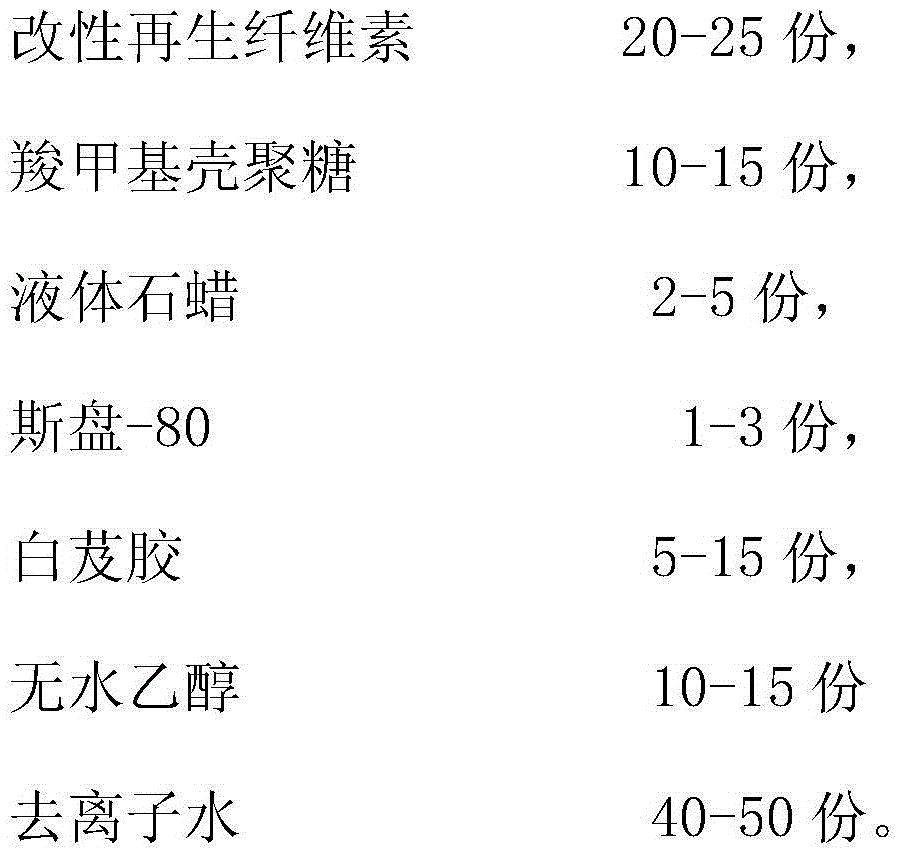

[0042] A spinning solution with hemostatic function, in parts by weight, comprising the following components:

[0043]

[0044] Its preparation method comprises the following steps:

[0045] (1) Mix and stir 4 parts of sodium stearate, 2 parts of acetic acid and deionized water evenly, add 21 parts of regenerated cellulose fiber knitted fabric, continue stirring, add ammonia water to adjust the pH to 10, ultrasonicate at 400W for 2.1 hours, add Excessive ethanol, obtain mixed dispersion liquid;

[0046] (2) Transfer the mixed dispersion obtained in step (1) to an autoclave, and react at 83°C for 40 minutes. After the reaction, cool the mixed dispersion to room temperature, filter, and wash with absolute ethanol until neutral to obtain modified regeneration cellulose;

[0047] (3) Mix and stir 3 parts of liquid paraffin, 2 parts of Span-80 and deionized water evenly, ultrasonicate for 22 minutes at a power of 330W, continue to add modified regenerated cellulose, 11 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com