Gradient functional anode for carbon-based solid oxide fuel cell and preparation method thereof

A solid oxide, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of commercialization without SOFC technology, complex system heat exchange design, prone to carbon deposition reaction, etc. Large-scale production, mature technology, and the effect of enhancing the catalytic activity of reforming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

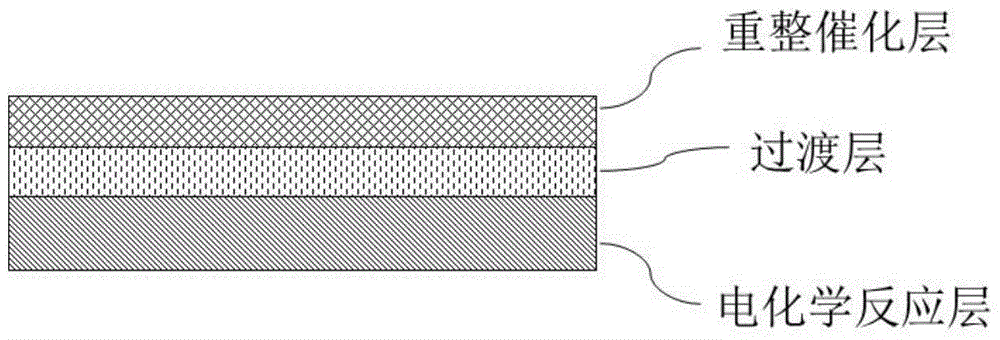

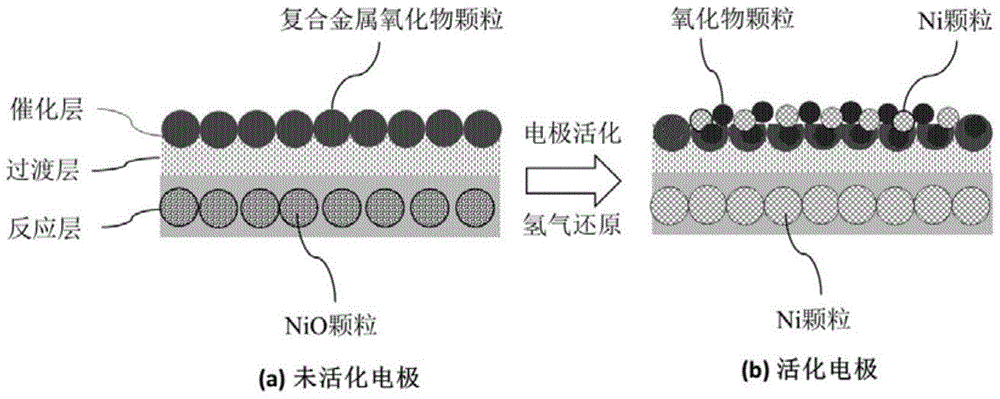

[0081] Co-sintering method for preparing functionally gradient anode

[0082] Using traditional methods to prepare a flat battery blank with an electrochemical reaction layer. The battery blank has a two-layer structure, which is an electrochemical reaction layer and an electrolyte layer. The anode electrochemical reaction layer is a mixture of NiO and YSZ (NiO and YSZ quality The ratio is 1:0.43), and the electrolyte layer material is pure YSZ. The thickness of the green electrochemical reaction layer is about 600-1500 μm, and the thickness of the electrolyte layer is about 40-60 μm. Dry naturally at room temperature in an air atmosphere.

[0083] Weigh two 5g portions of LaNi 0.4 Ti 0.6 O 3 (LNT) composite metal oxide powder and a 25g portion of YSZ electrolyte powder. One part of LNT powder is added with 4g of binder and 0.25g of starch pore former, after ball milling, the screen printing slurry for reforming catalyst layer is obtained; one part of LNT powder is fully mixed wi...

Embodiment 2

[0085] Using two-step sintering molding method to prepare functionally gradient anode

[0086] The flat battery blank with electrochemical reaction layer is prepared by traditional method, and it is ready for use after drying. The battery blank has a two-layer structure, which is an electrochemical reaction layer and an electrolyte layer. The anode electrochemical reaction layer is a mixture of NiO and SDC (the mass ratio of NiO and YSZ is 1:0.8), and the electrolyte layer material is pure SDC. The thickness of the electrochemical reaction layer is approximately 600-1500 μm, and the thickness of the electrolyte layer is approximately 40-60 μm. After drying in an air atmosphere, the battery blank is sintered at 1350°C for 4 hours to form the ceramic structure of the battery blank; it can also be sintered at 1450°C for 3 hours to form the ceramic structure of the battery blank.

[0087] Weigh two 5g portions of LaNi 0.4 Ti 0.6 O 3 (LNT) composite metal oxide powder and a 20g portion...

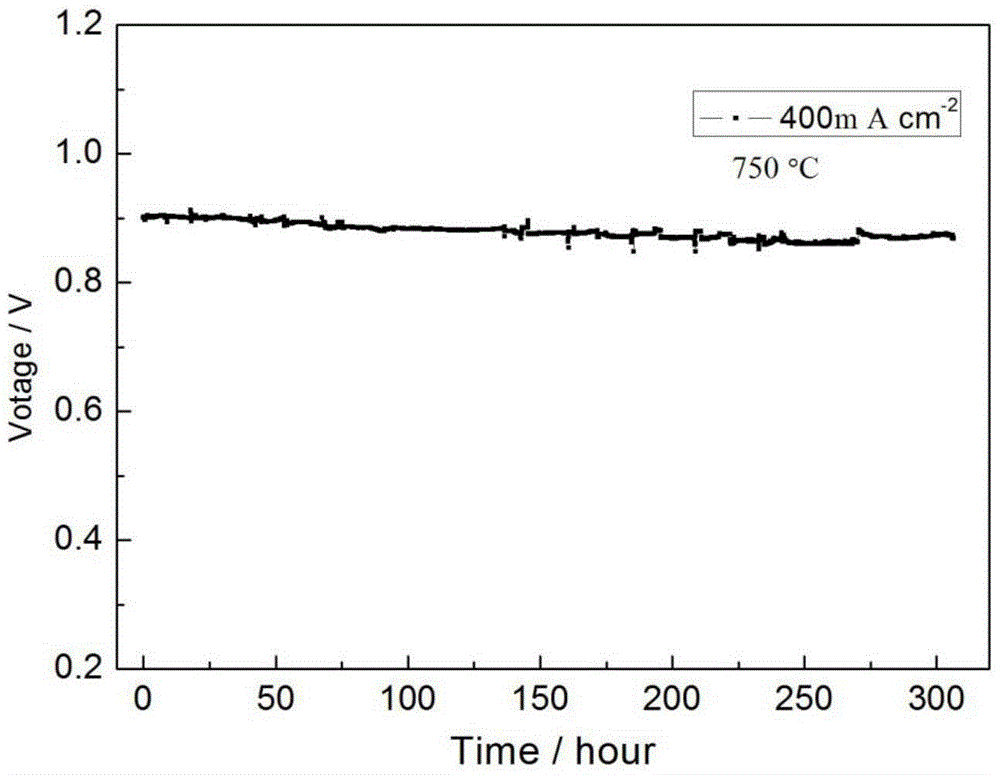

Embodiment 1-5

[0090]

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com