A kind of wheat straw bio-based ion-exchange adsorption material and preparation method thereof

An ion exchange and adsorption material technology, applied in the field of natural biomass-based materials and their surface functionalization modification, can solve the problems of difficult large-scale production, self-polymerization reaction conditions, low utilization rate of monomers, etc., and achieve easy degradation. , rich sources, significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

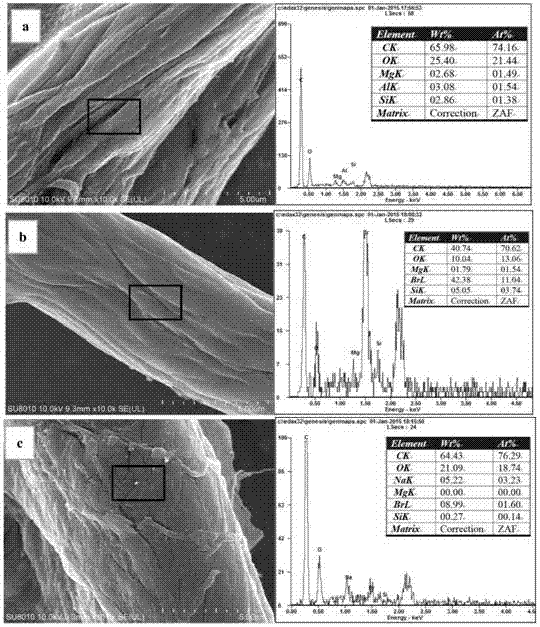

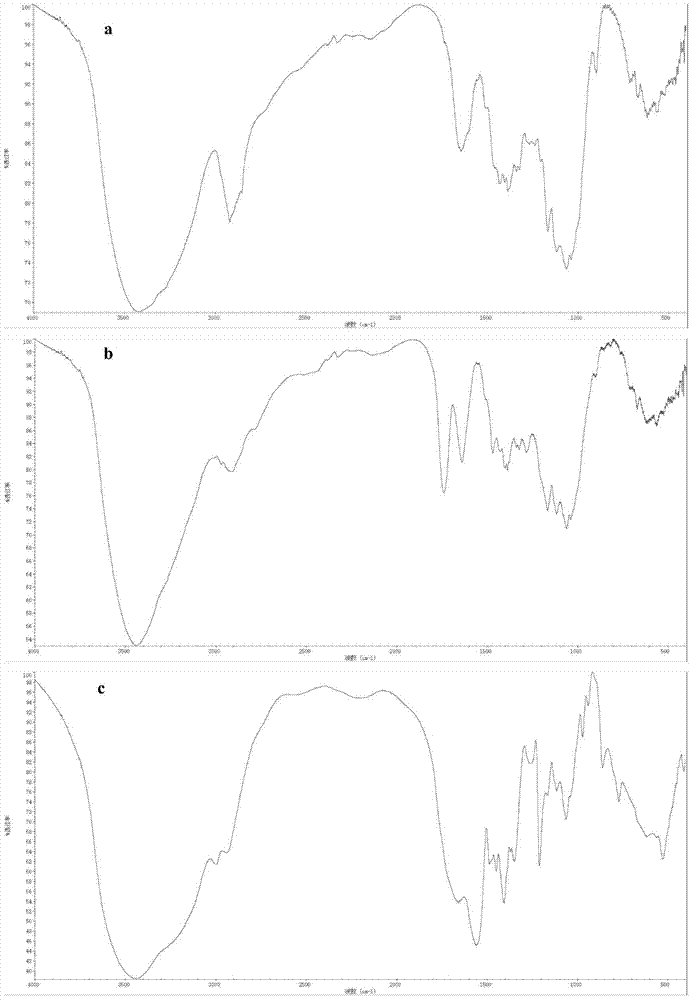

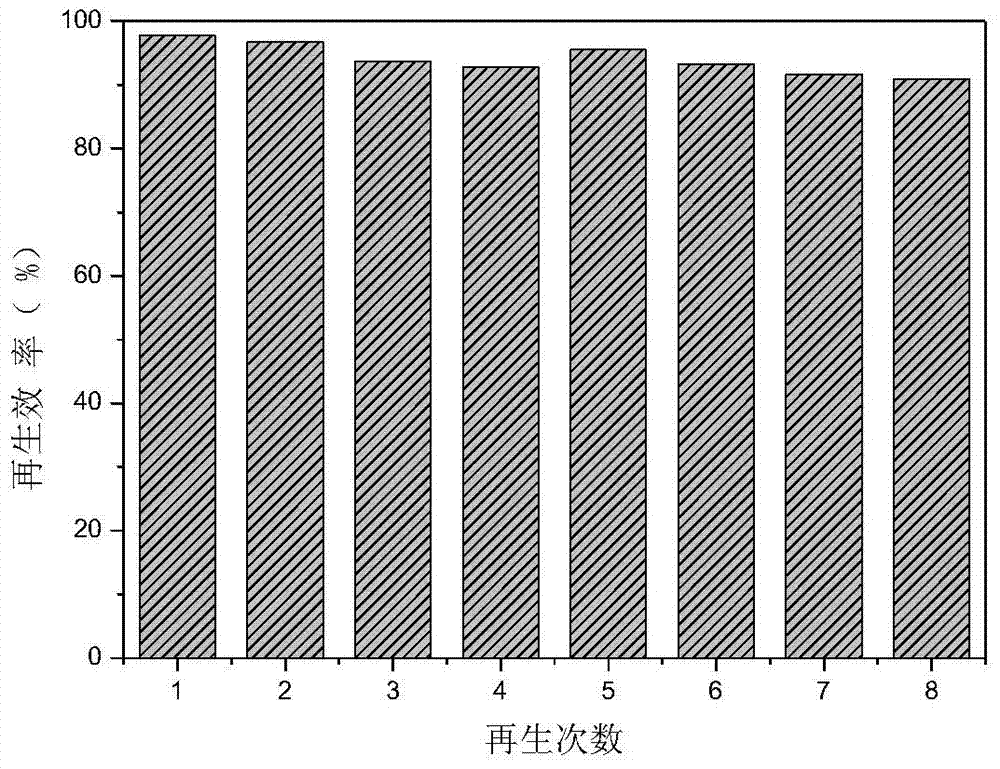

[0034] A wheat straw bio-based ion-exchange adsorption material, the preparation method of which comprises the following steps:

[0035] 1) Washing the wheat straw, drying it, placing it in a plant pulverizer, pulverizing it, and sieving through 80 meshes to obtain the wheat straw fine fiber.

[0036] 2) Immerse the wheat straw fine fibers in 15wt% NaOH solution for 24 hours, carry out decrystallization treatment, then filter and wash with water until neutral, obtain decrystallized wheat straw, dry for later use.

[0037] 3) Weigh 1g of decrystallized wheat straw into a round-bottomed flask filled with 50mL of N,N-dimethylformamide, add 4mL of bromoisobutyryl bromide and 1mL of pyridine dropwise, and stir at 60°C under magnetic stirring. React for 24 hours. After the reaction is completed, wash with tetrahydrofuran and acetone, then wash with excess deionized water and filter, and dry at room temperature to constant weight to obtain brominated wheat straw with initiator groups...

Embodiment 2

[0043] A wheat straw bio-based ion-exchange adsorption material, the preparation method of which comprises the following steps:

[0044] 1) Washing the wheat straw, drying it, placing it in a plant pulverizer, pulverizing it, and sieving through 80 meshes to obtain the wheat straw fine fiber.

[0045] 2) The fine fibers of wheat straw were immersed in 25wt% NaOH solution for 6 hours for decrystallization treatment, and then filtered and washed until neutral to obtain decrystallized wheat straw, which was dried for later use.

[0046] 3) Weigh 1.0 g of decrystallized wheat straw and add it to a round-bottomed flask containing 30 mL of N,N-dimethylformamide, add 3 mL of bromoisobutyryl bromide and 1 mL of pyridine dropwise, and stir at 25 The reaction was carried out at ℃ for 24 hours. After the reaction was completed, it was rinsed with tetrahydrofuran and acetone, then washed with excess deionized water and filtered, and dried at room temperature to constant weight to obtain b...

Embodiment 3

[0050] A wheat straw bio-based ion-exchange adsorption material, the preparation method of which comprises the following steps:

[0051] 1) Washing the wheat straw, drying it, placing it in a plant pulverizer, pulverizing it, and sieving through 80 meshes to obtain the wheat straw fine fiber.

[0052] 2) The fine fibers of wheat straw were immersed in 10wt% NaOH solution for 24 hours for decrystallization treatment, and then filtered and washed until neutral to obtain decrystallized wheat straw, which was dried for later use.

[0053] 3) Weigh 1g of decrystallized wheat straw into a round-bottomed flask filled with 60mL of N,N-dimethylformamide, add 6mL of bromoisobutyryl bromide and 2mL of pyridine dropwise, and stir at 40°C under magnetic stirring React for 12 hours. After the reaction is completed, wash with tetrahydrofuran and acetone, then wash with excess deionized water and filter, and dry to constant weight at room temperature to obtain brominated wheat straw with init...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com