A kind of honeycomb low-temperature denitrification catalyst and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high active temperature window, difficulty in catalyst preparation, and increased operating costs and other problems, to achieve high low-temperature activity, broaden the activity temperature window, and improve the effect of microscopic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

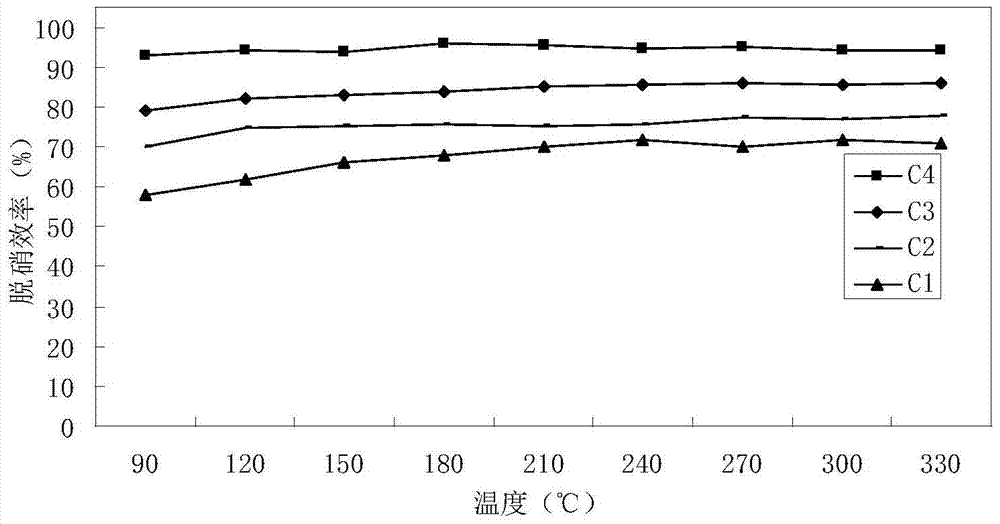

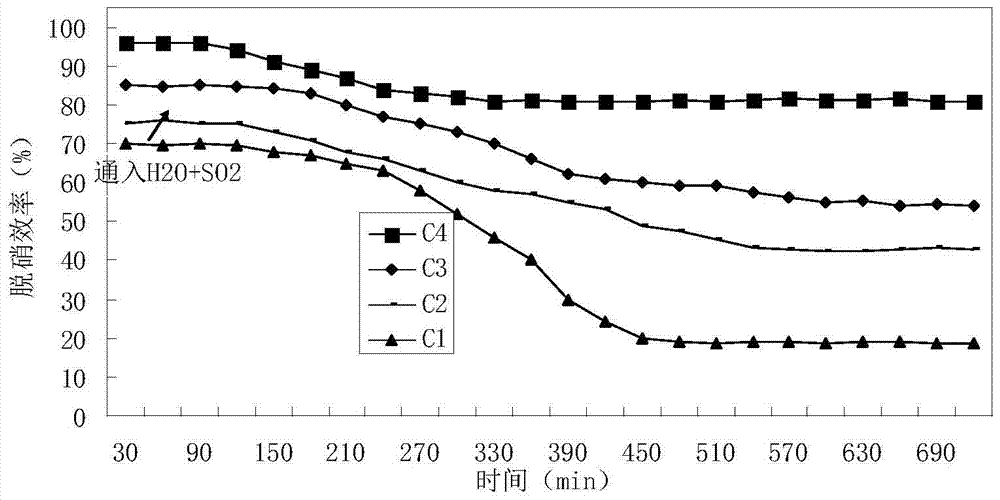

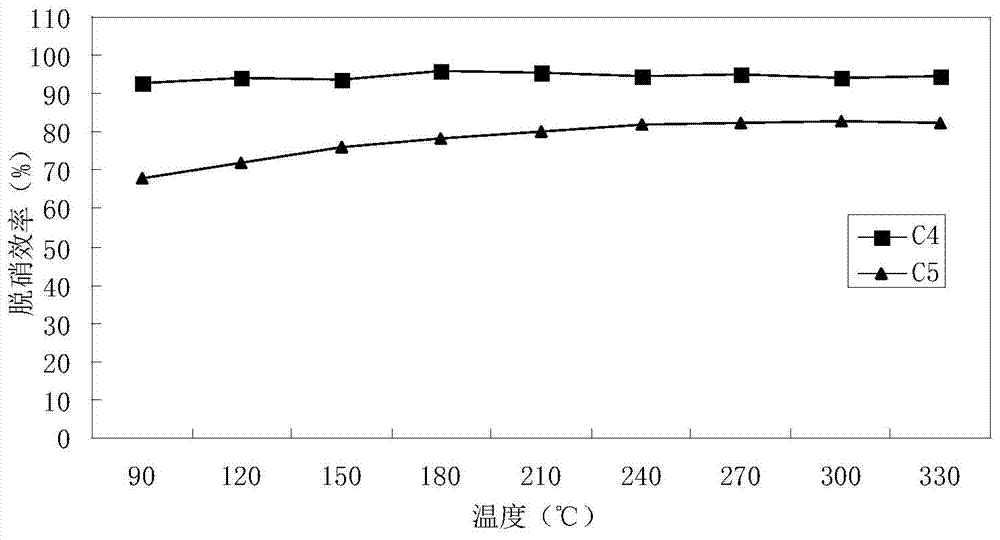

[0037] Example 1 Preparation of Catalyst C1.

[0038] Dissolve manganese acetate tetrahydrate, ferric nitrate nonahydrate, and cerium nitrate hexahydrate in 50ml deionized water to form a mixed solution, and add 20g of γ-Al to the solution 2 o 3 Powder, control the mass ratio of metal elements to carrier Mn:Fe:Ce:Al 2 o 3 =8:2:4:100. First, use a magnetic constant temperature stirrer to stir at a constant temperature of 40 ° C for 1 h, then put the sample into an ultrasonic generator for ultrasonic impregnation, the ultrasonic power is 300 W, the frequency is 30 Khz, and the impregnation time is 2 h. Then add 15g binder and make slurry, the composition of binder is: colloidal silicon dioxide 60wt%, polyvinyl alcohol 25wt% and carboxymethyl cellulose 15wt%. After stirring, put the cordierite ceramic honeycomb carrier into the slurry and impregnate it with the above ultrasonic parameters for 5 hours, then put the impregnated cordierite ceramic honeycomb carrier into a microw...

Embodiment 2

[0039] Example 2 Preparation of Catalyst C2.

[0040] The implementation steps are the same as in Example 1, other conditions remain unchanged, and the mass ratio of Mn:Fe:Ce is changed to 8:2:6 to prepare catalyst C2.

Embodiment 3

[0041] Example 3 Preparation of Catalyst C3.

[0042] The implementation steps are the same as in Example 1, other conditions remain unchanged, and the mass ratio of Mn:Fe:Ce is changed to 8:4:6 to prepare catalyst C3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com