Manufacturing method of molybdenum tube target

A manufacturing method and target technology, which are applied in the field of magnetron sputtering and molybdenum tube target manufacturing, can solve the problems of limiting the size of molybdenum extrusion billet, low material utilization rate, long process flow, etc., and achieve a long finished product length. , the effect of reducing energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

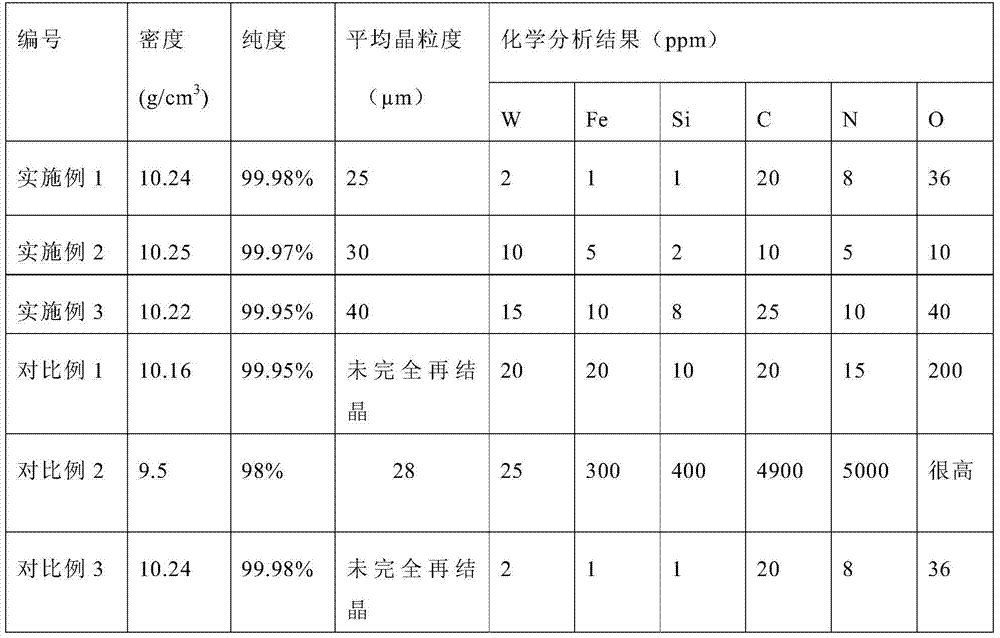

Embodiment 1

[0027] The specifications of the finished molybdenum tube target material (ie hollow cylindrical target material) prepared in this example are: the diameter of the outer circle / inner hole is 155 / 125 mm; the length is 6000 mm.

[0028] The specific preparation method is as follows:

[0029] (1) Preparation of molybdenum ingot: use Mo-1 powder with 3 μm and 99.98% purity as raw material, and load the powder

[0030] Afterwards, cold isostatic pressing at 220MPa, and after shaping, keep hydrogen at 2400°C for 12 hours

[0031] For sintering, the hydrogen flow rate is 4m 3 / h, after cooling out of the furnace, the diameter of the outer circle / inner hole is

[0032] 305 / 127mm, molybdenum tube blank with a length of 1010mm.

[0033] (2) One-time machining: According to the extrusion requirements, the above-mentioned molybdenum ingot sintered by powder is machined into a cylindrical ingot with the following inner hole and outer circle. The diameter of the outer circle / inner hole o...

Embodiment 2

[0039] The specifications of the finished molybdenum tube target (that is, the hollow cylindrical target) prepared in this example are: the diameter of the outer circle / inner hole is 73 / 60mm; the length is 1000mm

[0040] The specific preparation method is as follows:

[0041] (1) Preparation of molybdenum ingots: use 2.5μm Mo-1 powder with a purity of 99.98% as the raw material, after loading the powder

[0042] Cold isostatic pressing at 250MPa, after shaping, keep hydrogen at 2300°C for 10 hours

[0043] Line sintering, hydrogen flow rate is 3m 3 / h, after cooling out of the furnace, the diameter of the outer circle / inner hole is 125 / 57mm,

[0044] Molybdenum ingots with a length of 410mm.

[0045] (2) One-time machining: According to the extrusion requirements, the molybdenum ingot sintered by the above powder is machined into a cylindrical ingot with the following inner hole and outer circle. The diameter of the outer circle / inner hole of the ingot is 120 / 60mm, The le...

Embodiment 3

[0051] The specifications of the finished molybdenum tube target (that is, the hollow cylindrical target) prepared in this example are: the diameter of the outer circle / inner hole is 160 / 133mm; the length is 5000mm

[0052] The specific preparation method is as follows:

[0053] (1) Preparation of molybdenum ingots: use 3.5μm Mo-1 powder with a purity of 99.98% as the raw material, after loading the powder

[0054] Cold isostatic pressing at 240MPa, after shaping, heat at 2350°C for 11 hours with hydrogen

[0055] Line sintering, hydrogen flow rate is 3.5m 3 / h, after cooling out of the furnace, the diameter of the outer circle / inner hole is

[0056] 305 / 135mm, molybdenum ingot with a length of 610mm.

[0057] (2) One-time machining: According to the extrusion requirements, the powder sintered molybdenum ingot is machined into a cylindrical ingot with the following inner hole and outer circle. The diameter of the outer circle / inner hole of the ingot is 300 / 225mm, and the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com