Printed fixed-point growth method of two-dimensional chalcogenide crystals

A chalcogen and crystal technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1. Controllable preparation of two-dimensional chalcogen atom crystal arrays

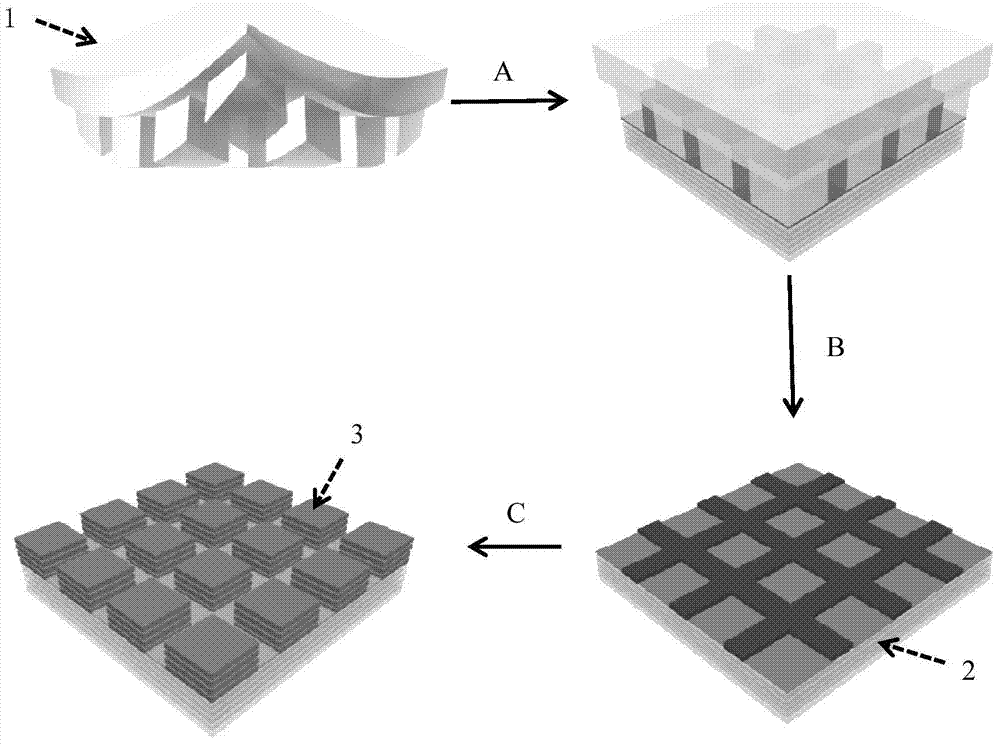

[0072] 1) will be as image 3 The array-type PDMS elastic stamp shown is soaked in ethanol liquid, and the PDMS oligomer is dissolved to form ink, which is then directly imprinted on the surface of the freshly peeled fluorophlogopite substrate with a thickness of 2 mm. The ethanol is completely volatilized by heating or vacuum drying to obtain a patterned and modified fluorophlogopite substrate.

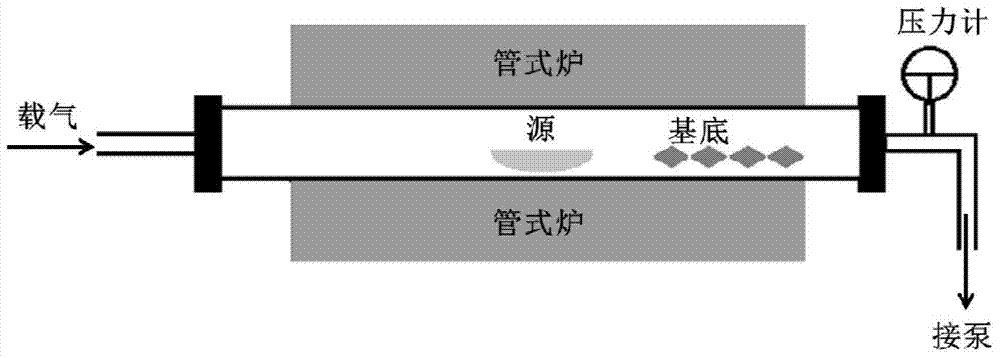

[0073] 2) The source (chalcogenide material In 2 Se 3 、 Bi 2 Se 3 , SnSe or GaSe) are ground into powder and placed in a semicircular quartz boat, placed in the center of the quartz tube, and the resulting patterned modified fluorophlogopite substrate is placed on the quartz at a distance of 7 to 16 cm from the source downstream of the airflow direction. In the tube, the deposition temperature of the patterned and modified fluorophlogopite substrate obtained in step 1) is 50-250°C lower...

Embodiment 2

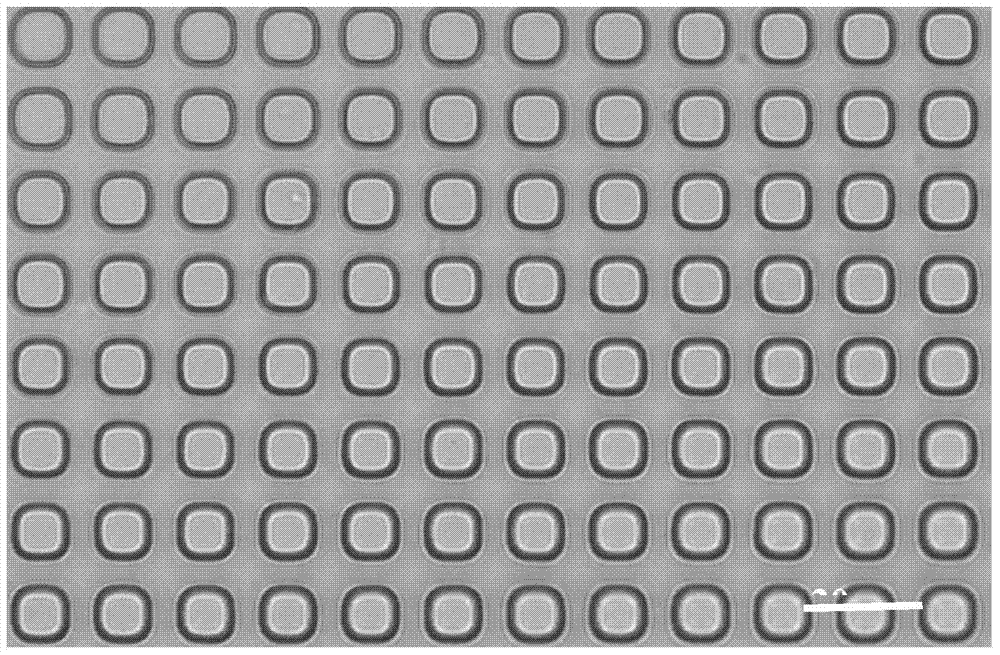

[0096] Example 2, the shape controllable preparation of two-dimensional chalcogen atom crystals

[0097] The specific operation steps of this embodiment are the same as those of Embodiment 1, except that PDMS elastic stamps with different shapes are used for growth to obtain a two-dimensional chalcogen atom crystal with the same shape as the stamp. This shows that the present invention can prepare shape-controllable two-dimensional chalcogen atom crystals. In this embodiment, the high-purity argon flow rate is 200 standard cubic centimeters per minute, and the system pressure is 6.7 kPa. In the physical vapor deposition, the growth was carried out at 490 degrees Celsius for 10 minutes.

[0098] Figure 21 is an optical microscope image of a continuous grid-like PDMS elastic stamp.

[0099] Figure 22 is to use Figure 21 The grid-like continuous Bi obtained from the stamp growth shown 2 Se 3 Optical microscope image of a 2D atomic crystal.

[0100] Figure 23 is to us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com