Ag alloy heat-insulating film and preparation method thereof

A heat-insulating film and alloy technology, applied in chemical instruments and methods, metal layered products, synthetic resin layered products, etc., can solve the problems of easy oxidation of metal Ag film, low production efficiency, low deposition rate, etc., and achieve good results. Spectral selective transmittance, high production efficiency, and high infrared blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

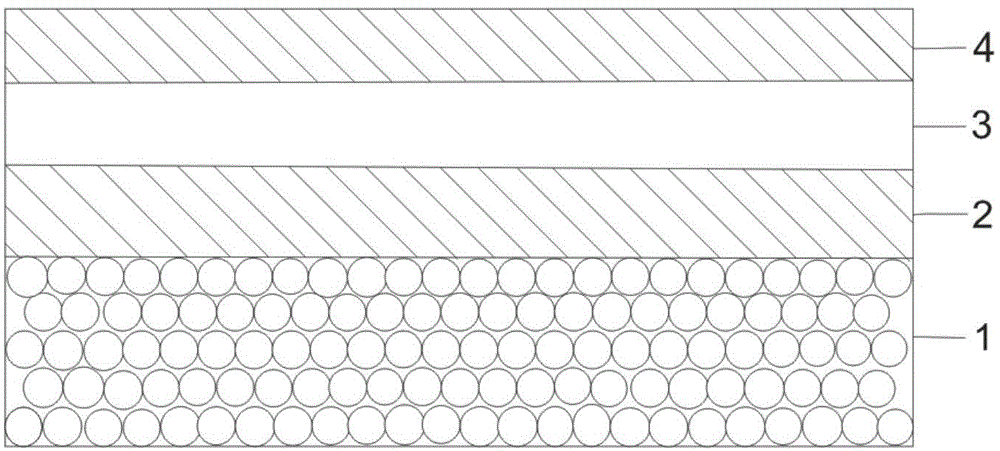

[0035] Select the substrate PET with a thickness of 100 μm, and use a roll-to-roll magnetron sputtering coating machine equipped with a magnetron sputtering medium-frequency twin target. When the substrate PET passes through several coating areas with good airtight isolation with the coating roller rotation On its other side, nickel-chromium alloy (Ni80%Cr20%) with a thickness of 0.2nm, silver-copper alloy (Ag92.5%Cu7.5%) with a thickness of 5nm and nickel-chromium alloy with a thickness of 0.2nm ( Ni80%Cr20%) three-layer film, namely the Ag alloy heat insulation film.

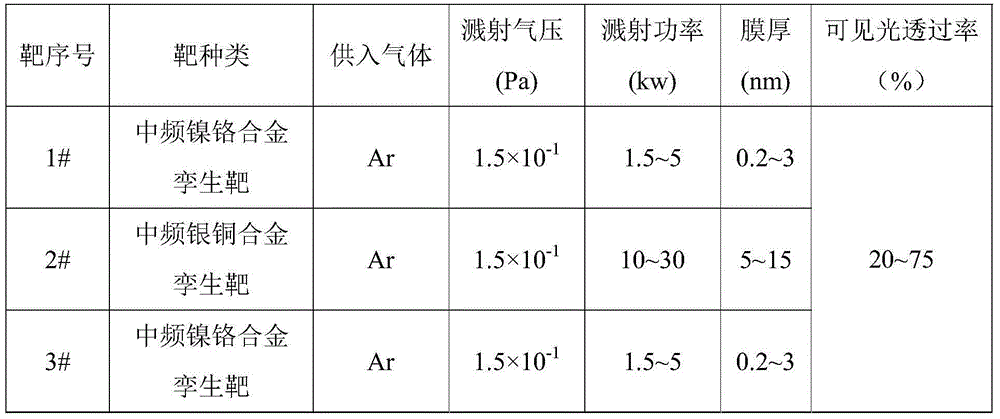

[0036] In this embodiment, a winding magnetron sputtering multi-target coating machine is used, and the specific process parameters are listed in the following table:

[0037]

Embodiment 2

[0039] Select the substrate PET with a thickness of 13 μm, and use a roll-to-roll magnetron sputtering coating machine equipped with a magnetron sputtering intermediate frequency twin target. When the substrate PET passes through several coating areas with good airtight isolation with the coating roller On the other side, nickel-chromium alloy (Ni80%Cr20%) with thickness of 3nm, silver-copper alloy (Ag92.5%Cu7.5%) with thickness of 15nm and nickel-chromium alloy with thickness of 3nm (Ni80% Cr20%) three-layer film, namely Ag alloy heat insulation film.

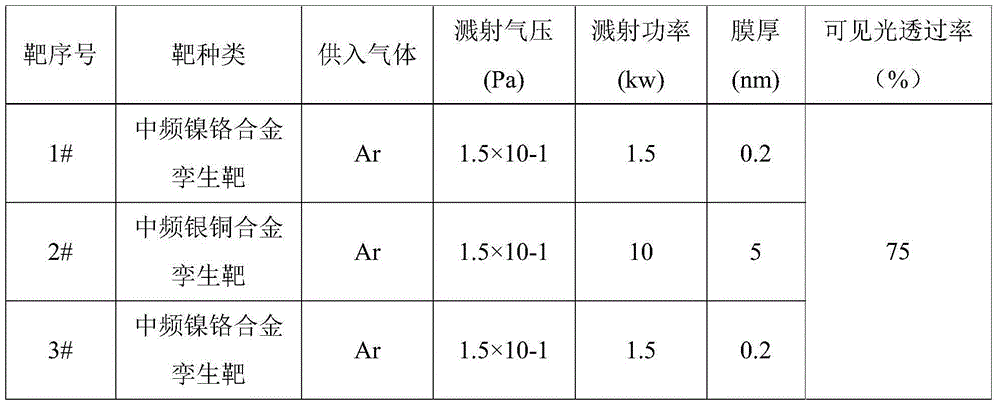

[0040] In this embodiment, a winding magnetron sputtering multi-target coating machine is used, and the specific process parameters are listed in the following table:

[0041]

Embodiment 3

[0043] Select the substrate PET with a thickness of 80 μm, and use a roll-to-roll magnetron sputtering coating machine equipped with a magnetron sputtering intermediate frequency twin target. When the substrate PET rotates with the coating roller and passes through several coating areas with good airtight isolation , on the other side, successively plate nickel-chromium alloy (Ni80%Cr20%) with a thickness of 1nm, silver-copper alloy (Ag92.5%Cu7.5%) with a thickness of 8nm and nickel-chromium alloy (Ni80%Cu7.5%) with a thickness of 1nm Cr20%) three-layer film, namely Ag alloy heat insulation film.

[0044] In this embodiment, a winding magnetron sputtering multi-target coating machine is used, and the specific process parameters are listed in the following table:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com