A method for treating sewage by using a biological fluidized bed

A technology of biological fluidized bed and fluidized bed reactor, which is applied in biological water/sewage treatment, chemical instruments and methods, special compound water treatment, etc. It can solve the problem that the filler is not easy to form film, the service life of the filler is short, and the start-up time is long. and other problems, to achieve the effects of easy microbial growth and film formation, prolonging the operating life and improving the quality of effluent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

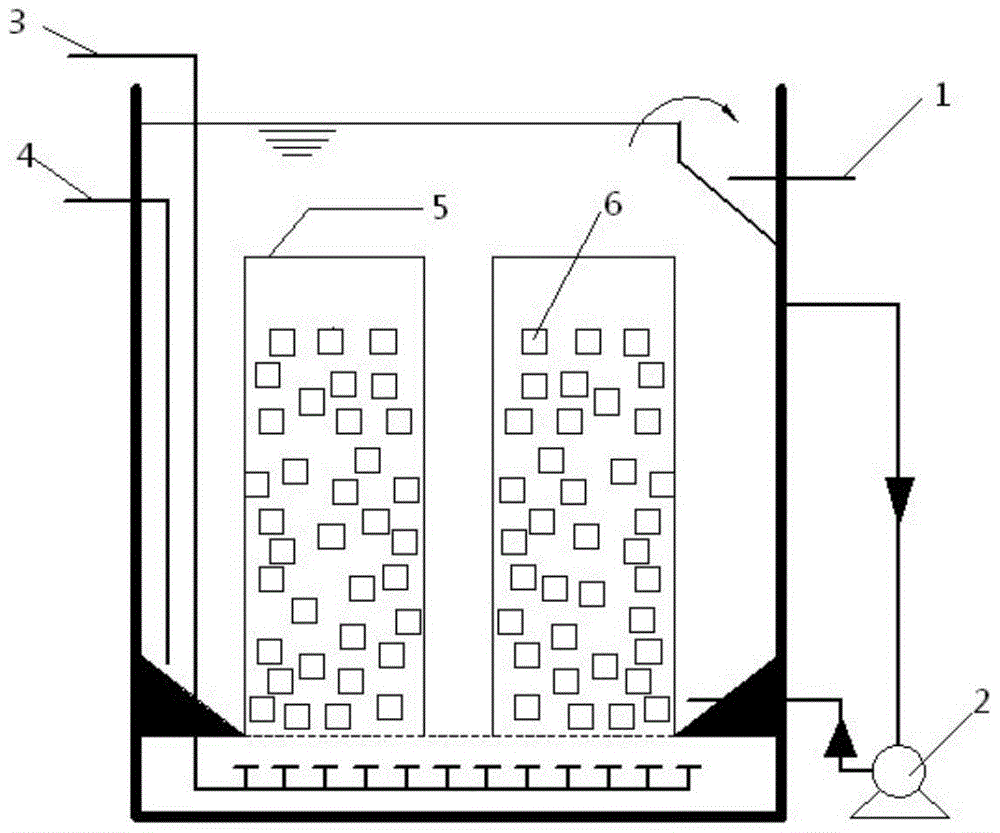

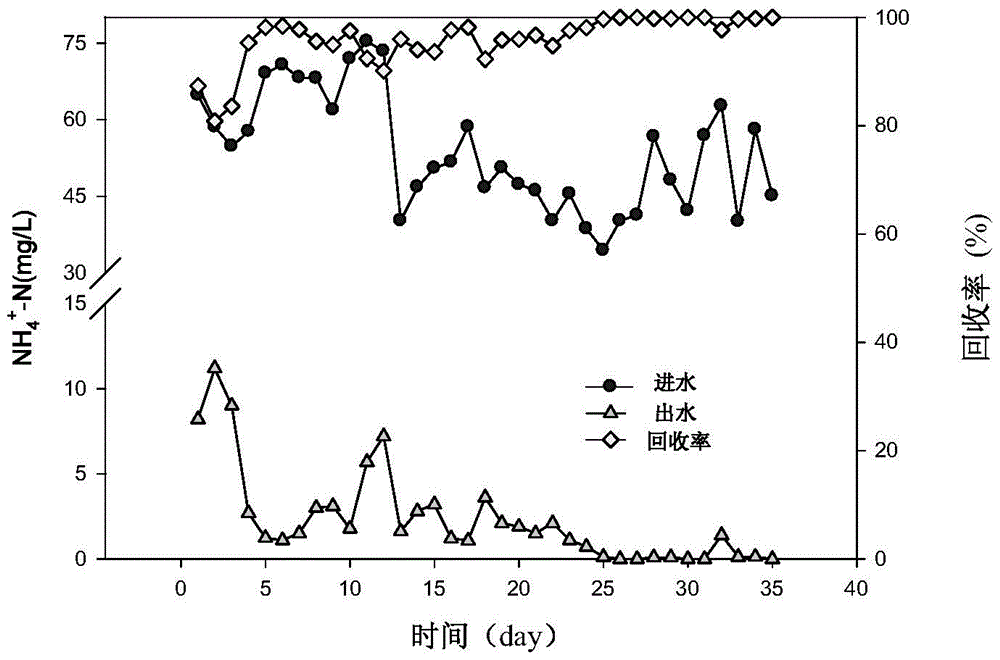

[0035] Example 1 Treatment of Domestic Sewage

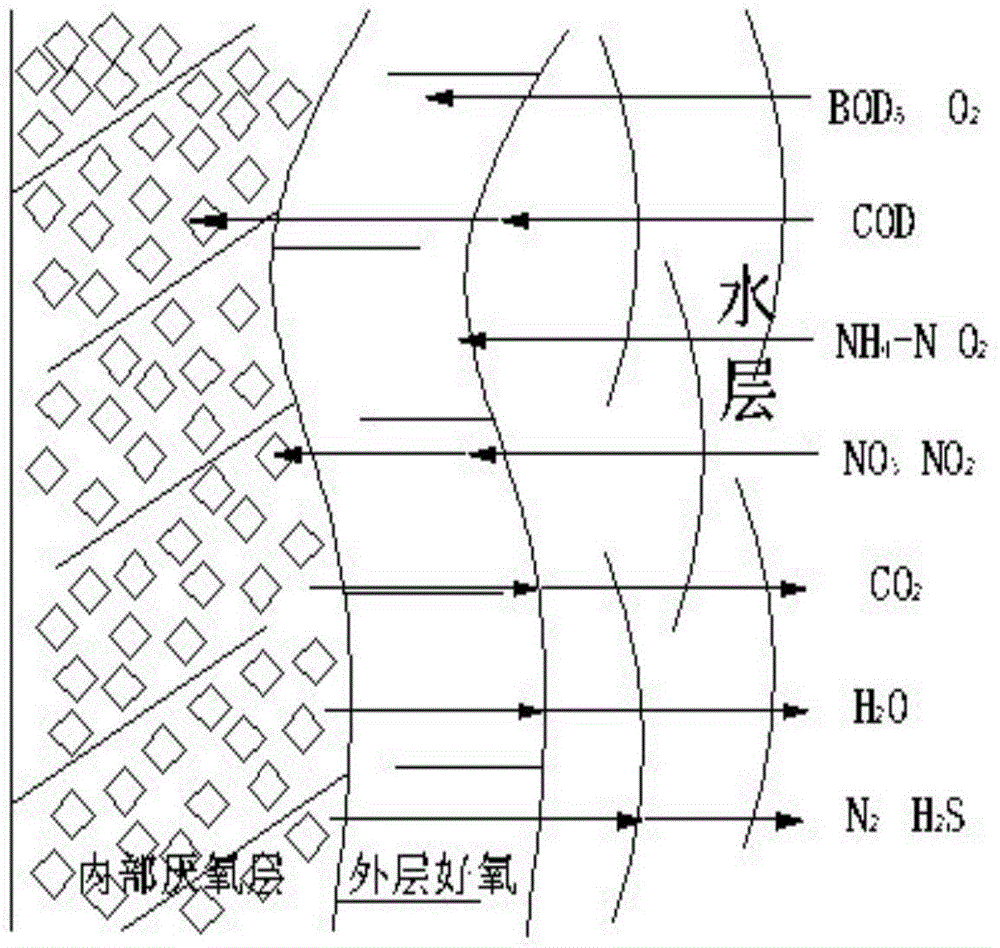

[0036] The sewage treatment capacity is 60L / d. Before treatment, the influent COD is 200mg / L~300mg / L, ammonia nitrogen is 30mg / L~60mg / L, total nitrogen is 40mg / L~70mg / L, and the reactor volume is 15L. Time 10h. Add 10% polyurethane sponge filler into the reactor, the filler size is 2.5×2.5×2.5cm, and the pore size is 15PPI. Inoculate 0.3% microbial agent, turn on the external circulation pump for water intake operation, control the dissolved oxygen in the reactor at 0.2mg / L~1.0mg / L in the early stage, and increase the aeration after 3 weeks of operation to control the dissolved oxygen at 2.0mg / L~ 3.0mg / L operation for 4 weeks, the treatment system is stable, the effluent COD is below 50mg / L, the ammonia nitrogen is below 2mg / L, and the total nitrogen is below 10mg / L.

[0037] As a control, the domestic sewage treatment experiment was carried out by using PVA ring filler instead of polyurethane sponge filler. The experimental res...

Embodiment 2

[0038] Example 2 Treatment of sewage in printing and dyeing industrial parks

[0039] The wastewater treatment is combined with the two-stage A / O process, in which the O pool adopts biological fluidized bed technology. The volume of the primary O1 pool reactor is 16m 3 , reaction residence time 8h, secondary O2 pool reactor volume 32m 3 , residence time 16h. Add 30% polyurethane sponge filler to the reactor and fix it with a grid frame. The packing specification is 5×5×5cm, and the pores are 10PPI. Inoculation of activated sludge (SV 30 ), so that SV 30 20%, and 0.3% of microbial agent after inflow operation, pre-aeration control dissolved oxygen O1 pool is 0.2mg / L~1.0mg / L, O2 pool is 0.2mg / L~1.0mg / L, run 4 After one week, increase the aeration rate so that the dissolved oxygen O1 pool is 1.0mg / L-2.0mg / L, and the O2 pool is 2mg / L-4mg / L. After 4 weeks of operation, the treatment system is stable. After treatment, wastewater COD can be reduced from 700mg / L to below 80mg / L...

Embodiment 3

[0040] Example 3 Treatment and restoration of lake and reservoir water bodies

[0041] Influent COD is 30mg / L, ammonia nitrogen is 2mg / L, total nitrogen is 3mg / L, reactor volume is 15L, and reaction residence time is 10h. Add 20% of polyurethane sponge filler into the reactor. The packing specification is 2.5×2.5×2.5cm, and the pore size is 15PPI. Inoculate the reactor with 0.2% denitrifying functional bacterial agent and a small amount of activated sludge (SV 30 10%), start the reactor, control the dissolved oxygen to 0.2mg / L~1.0mg / L, inoculate the ammonia oxidizing bacteria after running for 2 weeks, and increase the aeration rate at the same time, so that the dissolved oxygen is controlled at 1.0mg / L~2.0 mg / L, after 3 weeks of operation, the system will produce stable water. After treatment, the COD of the water will be below 20mg / L, the ammonia nitrogen will be below 1.0mg / L, and the total nitrogen will be below 1.0mg / L, meeting the Class III water standard for surface w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com