Disperse blue 56 primary nitrification and refining mother liquor wastewater treatment method

A treatment method, disperse blue technology, applied in natural water body treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of no public treatment methods, etc., to increase added value, simple process flow, economical treatment cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

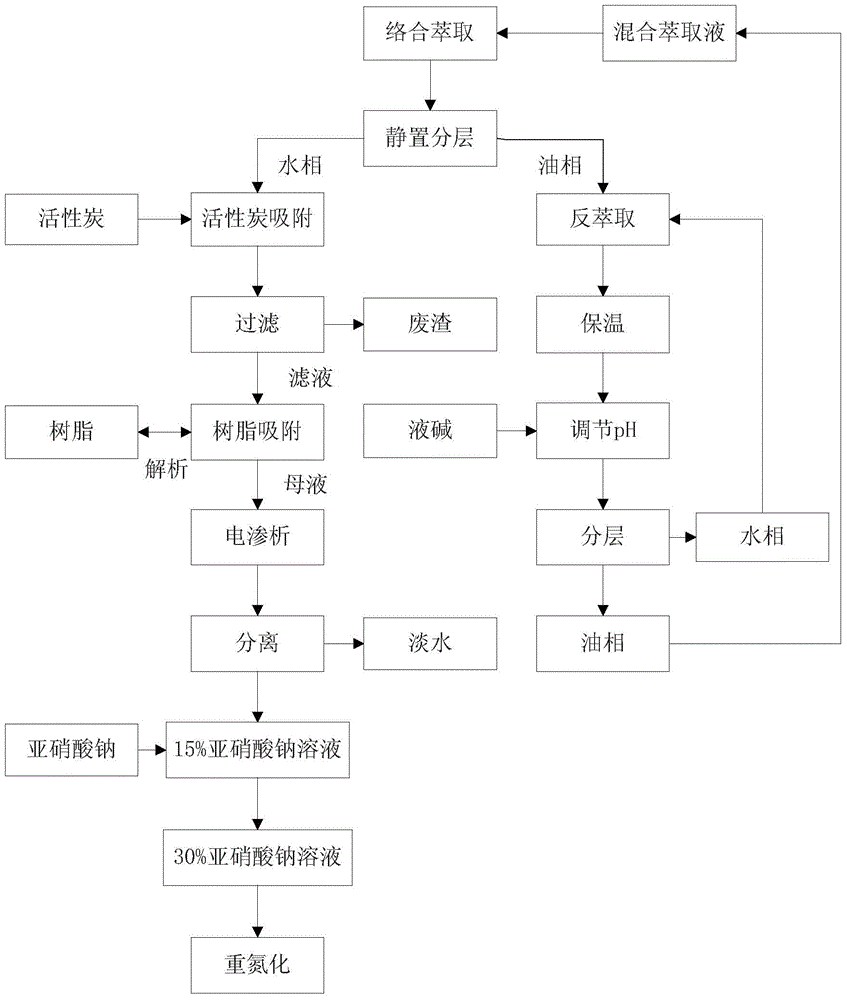

Method used

Image

Examples

Embodiment 1

[0038] After preliminary filtration of Disperse Blue 56 primary nitrification refining mother liquor wastewater, the measured pH is 11.42, COD is about 275000mg / L, based on the quality of wastewater, it contains 1.2% sodium nitrite, 0.1% sodium sulfite, and 0.02% sodium sulfate.

[0039] (1) Complex extraction: Mix 300 mL of extractant {extractant is trioctylamine: sulfonated kerosene = 1:2 (volume ratio)} with 100 mL of waste water and stir evenly, and pass nitrogen oxide NO x Adjust the pH of the gas to 3, aerate for 1 hour and then stand for 0.5 hours to separate the oil phase I and the water phase I.

[0040] After the reaction, the color of the oil phase I was deep red and black, and the water phase I was a red transparent clear liquid. The COD of the water phase I = 1600 mg / L, based on the mass of the water phase I, the content of sodium nitrite is 7%, the content of sodium nitrate is 0.1%, and the content of sodium sulfate is 0.03%.

[0041] (2) Back extraction: add 10% sodium...

Embodiment 2

[0060] After preliminary filtration of Disperse Blue 56 primary nitrification refining mother liquor wastewater, the measured pH is 11.3, COD is about 279050mg / L, based on the quality of the wastewater, it contains 1.2% sodium nitrite, 0.1% sodium sulfite, and 0.02% sodium sulfate.

[0061] (1) Complex extraction: Mix 300mL of extractant {extractant is trioctylamine: sulfonated kerosene = 1:2 (volume ratio)} with 100mL of waste water and stir evenly, then pass SO 2 The gas was adjusted to pH 2.5, reacted at room temperature for 1 hour and then allowed to stand for 0.5 hour to obtain oil phase I and water phase I by layering.

[0062] After the reaction, the color of the oil phase I was deep red and black, and the water phase I was a reddish transparent clear liquid. The COD of the water phase I=603mg / L, based on the mass of the water phase I, the sodium nitrite content is 7%, the sodium nitrate content is 0.1%, and the sodium sulfate content is 0.02%.

[0063] (2) Back extraction: Ad...

Embodiment 3

[0082] After preliminary filtration of Disperse Blue 56 primary nitrification and refining mother liquor wastewater, the measured pH is 11.3 and COD is about 279050mg / L. Based on the quality of the wastewater, it contains 0.8% sodium nitrite, 0.1% sodium sulfite, and 0.8% sodium sulfate.

[0083] (1) Complexation extraction: Mix 300 mL of extractant {extractant is trioctylamine: sulfonated kerosene = 1:2 (volume ratio)} with 100 mL of wastewater, and use Disperse Blue 56 for secondary nitrification wastewater (containing about 25 sulfuric acid). %) Adjust its pH to 2.5, stir and react at room temperature for 0.5 hours and then stand for 0.5 hours to obtain oil phase I and water phase I by layering.

[0084] After the reaction, the color of the oil phase I was deep red and black, and the water phase I was a reddish transparent clear liquid. The COD of the water phase I = 321 mg / L, based on the mass of the water phase I, the sodium nitrite content is 0.2%, the sodium nitrate content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com