Treatment method of industrial refuse landfill percolate

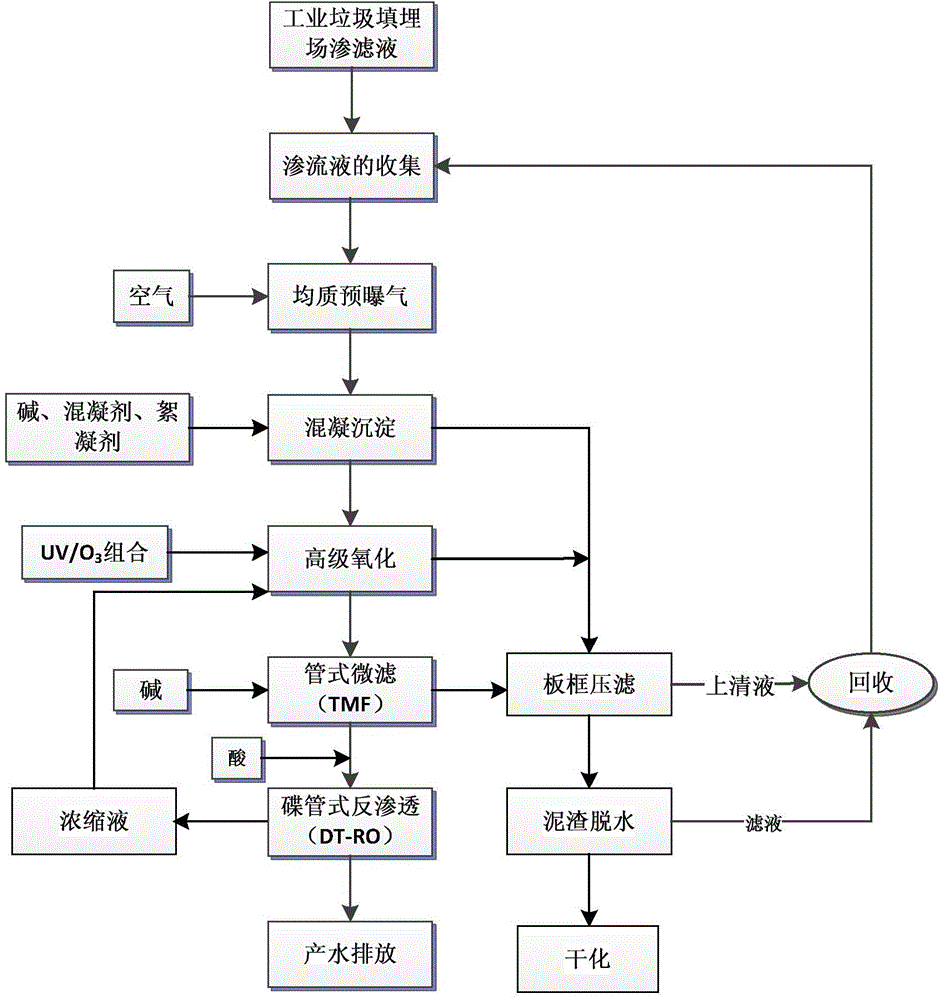

A treatment method and technology for industrial waste, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of long process flow, high concentration, high investment cost and operating cost , to achieve the effect of good treatment effect, simple process and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The combined process disclosed in the present invention is used to treat the leachate of an industrial waste landfill in an industrial waste landfill in Taizhou, Zhejiang. The leachate of the industrial waste landfill is mainly after landfilling and dismantling electrical appliances, chemical waste, leftover materials, etc. The resulting leachate, the COD concentration of the leachate before treatment is 8500mg / L, the BOD concentration is 75mg / L, and the NH 3 -N concentration is 600mg / L, suspended solids concentration (SS) concentration is 1100mg / L, total lead concentration is 5mg / L, total nickel concentration is 2.5mg / L, total zinc concentration is 1.5mg / L, total copper concentration The concentration is 12mg / L.

[0039] (1) Use a double-pipe DN150 conveying system to collect leachate from industrial waste landfills, and collect the leachate into the storage tank, and feed the leachate with a ventilation volume of 0.6m 3 / m 3 The air is pre-aerated, and then the leac...

Embodiment 2

[0045] The combined process disclosed in the present invention is used to treat the leachate of an industrial waste landfill in an industrial waste landfill in Taizhou, Zhejiang. The leachate of the industrial waste landfill is mainly after landfilling and dismantling electrical appliances, chemical waste, leftover materials, etc. The resulting leachate, the COD concentration of the leachate before treatment is 5400mg / L, the BOD concentration is 40mg / L, and the NH 3 -The concentration of N is 380mg / L, the concentration of suspended solids (SS) is 1000mg / L, the concentration of total lead is 3mg / L, the concentration of total nickel is 1.8mg / L, the concentration of total zinc is 0.8mg / L, and the concentration of total copper The concentration is 9mg / L.

[0046] (1) Use a double-pipe DN150 conveying system to collect leachate from industrial waste landfills, and collect the leachate into the storage tank, and feed the leachate with a ventilation volume of 0.75m 3 / m 3 The air i...

Embodiment 3

[0052] The combined process disclosed in the present invention is used to treat the leachate of an industrial waste landfill in an industrial waste landfill in Taizhou, Zhejiang. The leachate of the industrial waste landfill is mainly after landfilling and dismantling electrical appliances, chemical waste, leftover materials, etc. The resulting leachate, the COD concentration of the leachate before treatment is 6000mg / L, the BOD concentration is 55mg / L, and the NH 3 -N concentration is 520mg / L, suspended solids concentration (SS) concentration is 900mg / L, total lead concentration is 8mg / L, total nickel concentration is 3.5mg / L, total zinc concentration is 5mg / L, total copper concentration It is 17mg / L.

[0053] (1) Use a double-pipe DN150 conveying system to collect leachate from industrial waste landfills, and collect the leachate into the storage tank, and feed the leachate with a ventilation volume of 0.6m 3 / m 3 The air is pre-aerated; then the leachate after aeration is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com