Method for preparing polymer liquid crystal membrane material with biomimic structure and use of material

A technology imitating cell membranes and liquid crystal materials, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high hydrophobicity and low degree of bionics, and achieve the effects of short production cycle, reduced environmental pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

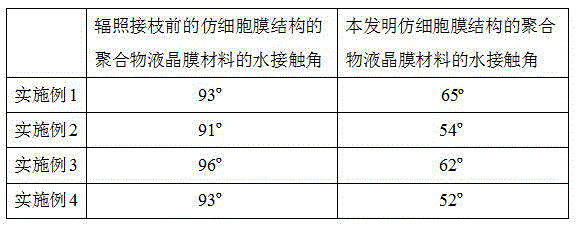

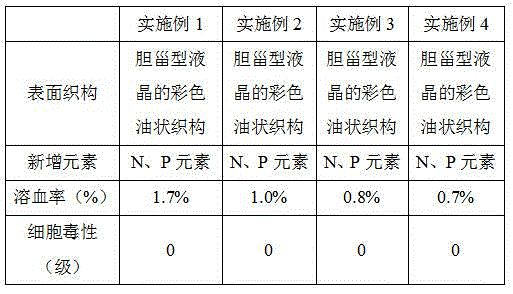

[0024] Embodiment 1, The preparation of the polymer liquid crystal membrane material of the imitation cell membrane structure of the present invention

[0025] (1) Dissolve butyl hydroxypropyl cellulose (BPC), which is in a liquid crystal state at physiological temperature, in acetone to form a homogeneous solution with a mass concentration of 1%, and spray it on a medical stainless steel sheet to form a BPC liquid crystal film;

[0026] (2) Set the area to 20cm 2 Immerse the BPC liquid crystal film in 20mL of 2wt% methacryloxyethyl phosphorylcholine and 0.02mol / L ferric sulfate solution, soak for 2h at room temperature; then irradiate with high-energy electron beams, with a total irradiation dose of 60kGy;

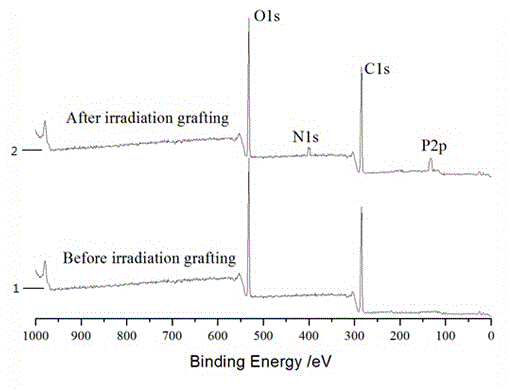

[0027] (3) Take out the irradiated liquid crystal film, wash it with deionized water, and dry it in vacuum at room temperature to obtain a polymer liquid crystal film material with a cell membrane structure: the hydroxyl group of polymethacryloyloxyethylphosphorylcholin...

Embodiment 2

[0028] Embodiment 2, The preparation of the polymer liquid crystal membrane material of the imitation cell membrane structure of the present invention

[0029] (1) Dissolve hydroxypropyl cellulose octyl ester (OPC) which is in a liquid crystal state at physiological temperature in tetrahydrofuran to form a homogeneous solution with a mass concentration of 6%, and cast it on a PET base film to form an OPC liquid crystal film;

[0030] (2) At room temperature, the area is 10cm 2 Immerse the OPC liquid crystal film in 10mL of 5wt% methacryloyloxyethylphosphorylcholine and 0.05mol / L copper nitrate solution for 12h; then irradiate with high-energy electron beams, with a total irradiation dose of 20kGy;

[0031] (3) Take out the irradiated liquid crystal film, wash it with deionized water, and dry it in vacuum at room temperature to obtain a polymer liquid crystal film material with a cell membrane structure: the hydroxyl group of polymethacryloyloxyethylphosphorylcholine grafted ...

Embodiment 3

[0032] Embodiment 3, The preparation of the polymer liquid crystal membrane material of the imitation cell membrane structure of the present invention

[0033] (1) Dissolve hydroxypropyl cellulose propyl ester (PPC), which is in a liquid crystal state at physiological temperature, in acetone to form a homogeneous solution with a mass concentration of 8%, and dip-coat it on a polyurethane tube to form a PPC liquid crystal film;

[0034] (2) Set the area to 10cm 2 The PPC liquid crystal film was immersed in 20mL of 8wt% methacryloxyethyl phosphorylcholine and 0.05mol / L ferric sulfate solution, soaked at 50°C for 1h; then used 60 Co-γ rays are irradiated in a nitrogen atmosphere, and the total irradiation dose is 30kGy;

[0035] (3) Take out the irradiated liquid crystal film, wash it with deionized water, and dry it in vacuum at 40°C to obtain a polymer liquid crystal film material with a cell membrane structure: surface-grafted polymethacryloyloxyethylphosphorylcholine Hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com