All-steel radial tyre and preparation method thereof

A technology for all-steel radial tires and tire blanks, which is applied in the field of tire manufacturing, can solve the problems of difficulty in unwinding the wrapping cloth, low production efficiency, and inability to unwind the adhesion, and achieve the effects of moderate viscosity, improved production efficiency, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For the convenience of description, the all-steel radial tire of the present invention and the preparation method thereof will be described in detail below.

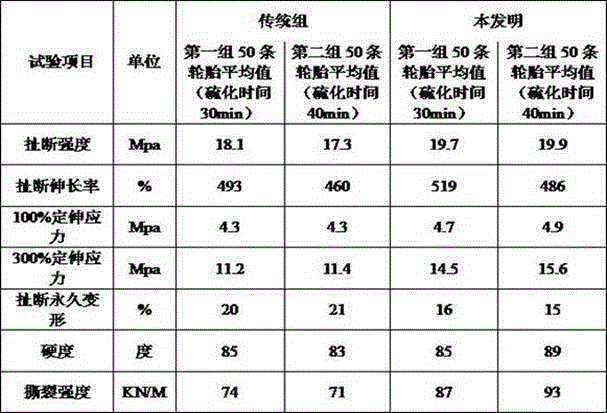

[0035] An all-steel radial tire, calculated in parts by weight, comprising 16.5 parts of styrene-butadiene resin, 10 parts of rubber powder, 3.5 parts of zinc oxide, 3.0 parts of stearic acid, 1.0 parts of rubber antioxidant RD, 10 parts of reinforcing resin, and natural rubber 100 parts of STR20, 50 parts of carbon black N375, 4.7 parts of aromatic oil, 10 parts of high styrene resin S6H, 1.0 part of microcrystalline wax, 2.74 parts of insoluble sulfur OT20, 1.0 part of rubber accelerator DZ, 1.0 part of rubber accelerator HMT, rubber Scorch retarder CTP 0.4 parts and small material 50.2 parts.

[0036] The composition of the rubber powder is obtained by smashing the waste tires and rubber products recovered by the second time, and the particle size after pulverization is 80 meshes, and metal impurities are picke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com