Polyglycolic acid resin composition, and method for producing same

A technology of resin composition and polyglycolic acid, which is applied in the field of polyglycolic acid resin composition, can solve the problems of molecular weight reduction, difficulty in extension molding, etc., and achieve the effects of high-quality moldability, excellent heat resistance, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

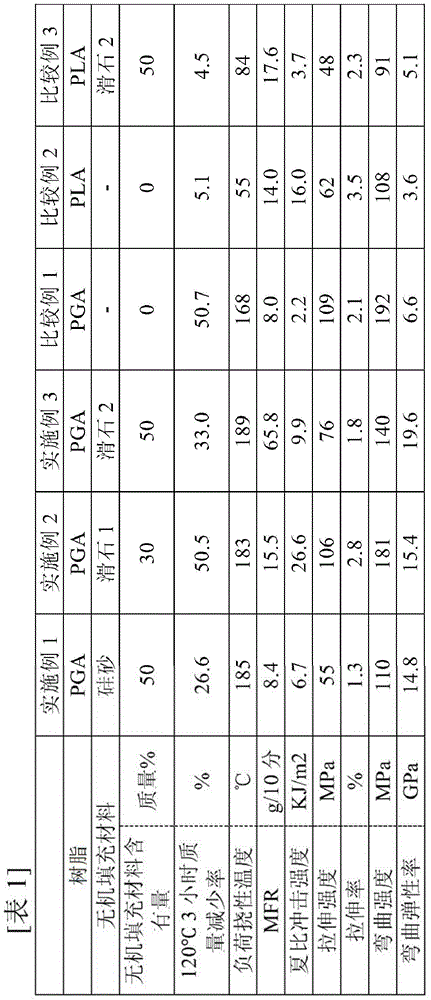

[0126] From the main supply port, PGA small particles are supplied to a two-screw extruder with a diameter (D) of 48 mm. The two-screw extruder is manufactured by Japan Placon Co., Ltd. The PGA small particles are manufactured by KUREHA Co., Ltd., Mw: 200 , 000, Mw / Mn: 2.2, MFR: 10g / 10 minutes, Tg: 43°C, Tm: 220°C, diameter 3mm x length 3mm, melted at a temperature of 200-240°C. In addition, as an inorganic filler, silica sand was supplied to a twin-screw extruder from a side supply port, and PGA and silica sand were melt-kneaded at a temperature of 240 to 250°C. Among them, the silica sand is: JFEmineral Co., Ltd., Sunshine silica sand, registered trademark No. 8, and the side supply port is: relative to the cylinder length (L) of the two-screw extruder, it is set at the side of the screw drive unit. From about 0.6L position. The content ratio of PGA and silica sand in the PGA composition was: 50% by mass: 50% by mass. The PGA and silica sand that have been melted and knead...

Embodiment 2

[0128] Evaluation test pieces were produced in the same manner as in Example 1 except that the inorganic filler was changed to talc, and the content ratio of PGA and talc was 70% by mass: 30% by mass. Among them, the talc is: manufactured by Nippon Talc Co., Ltd., registered trademark micro-ace L-1, with an average particle size of 5 μm, a moisture content of 0.2%, and an apparent density of 0.15 g / cm 3 , hereinafter referred to as "Talc 1". The test results of the prepared evaluation test piece at 120°C for 3 hours, mass reduction rate, load deflection temperature, MFR, Charpy impact strength, tensile strength and elongation ratio, flexural strength and flexural modulus are shown in Table 1 . In addition, after the evaluation test piece of the PGA composition was buried in the soil at a temperature of 60°C for two months, it was dug out for visual judgment, and it was found that the evaluation test piece was completely damaged, so it was judged that the PGA composition had b...

Embodiment 3

[0130] In addition to changing the inorganic filler to talc, the method of supplying the inorganic filler, talc 2, to the twin-screw extruder is as follows: 30% by mass of the total amount of talc from the main supply port, 70% by mass of the total amount of talc from Evaluation test pieces were produced in the same manner as in Example 1 except that the side supply ports were provided separately. Among them, the talc is: manufactured by Nippon Talc Co., Ltd., Shimugon average particle size 8 μm, moisture content 0.2%, apparent density 0.29 g / cm 3 , hereinafter also referred to as "Talc 2". The test results of the prepared evaluation test piece at 120°C for 3 hours, mass reduction rate, load deflection temperature, MFR, Charpy impact strength, tensile strength and elongation ratio, flexural strength and flexural modulus are shown in Table 1 . In addition, after the evaluation test piece of the PGA composition was buried in the soil at a temperature of 60°C for two months, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com