Cutting wire for low-magnesium unidirectional wire running and manufacturing method thereof

A cutting line, one-way technology, applied in the direction of electrode manufacturing, manufacturing tools, electric processing equipment, etc., can solve the problems of high manufacturing cost, immobile cutting, and fast electric corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

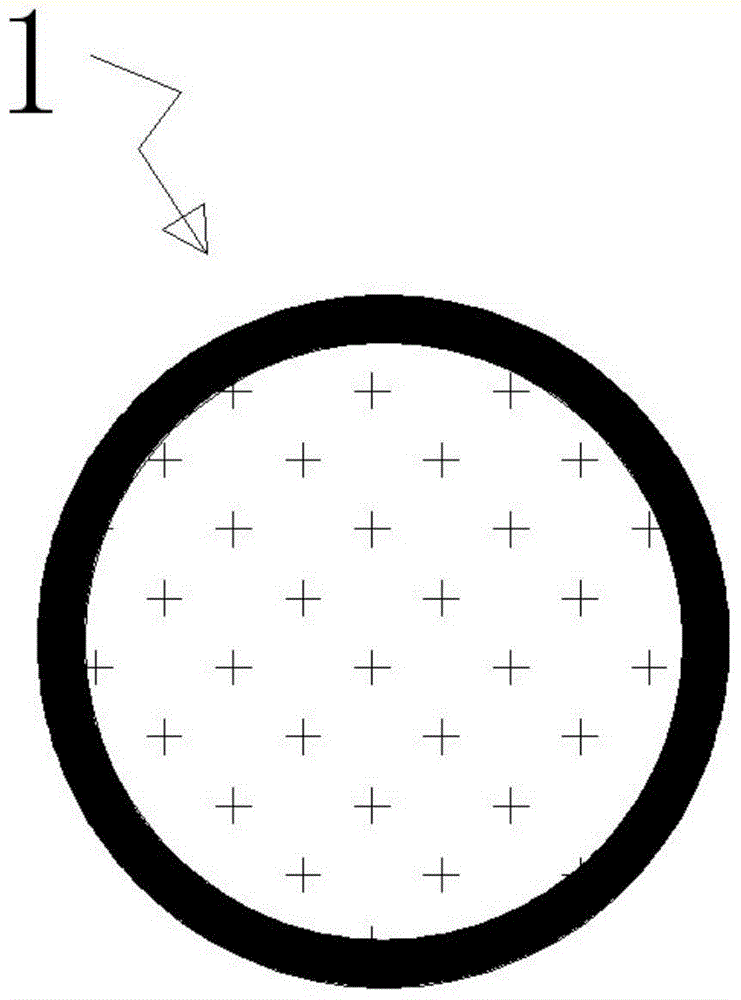

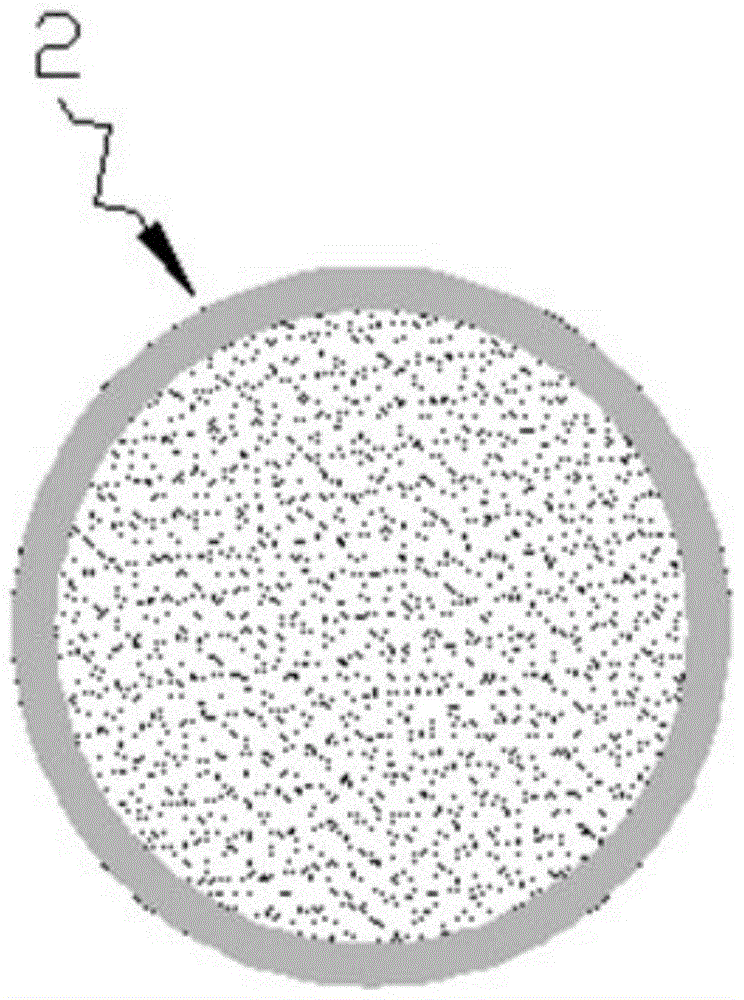

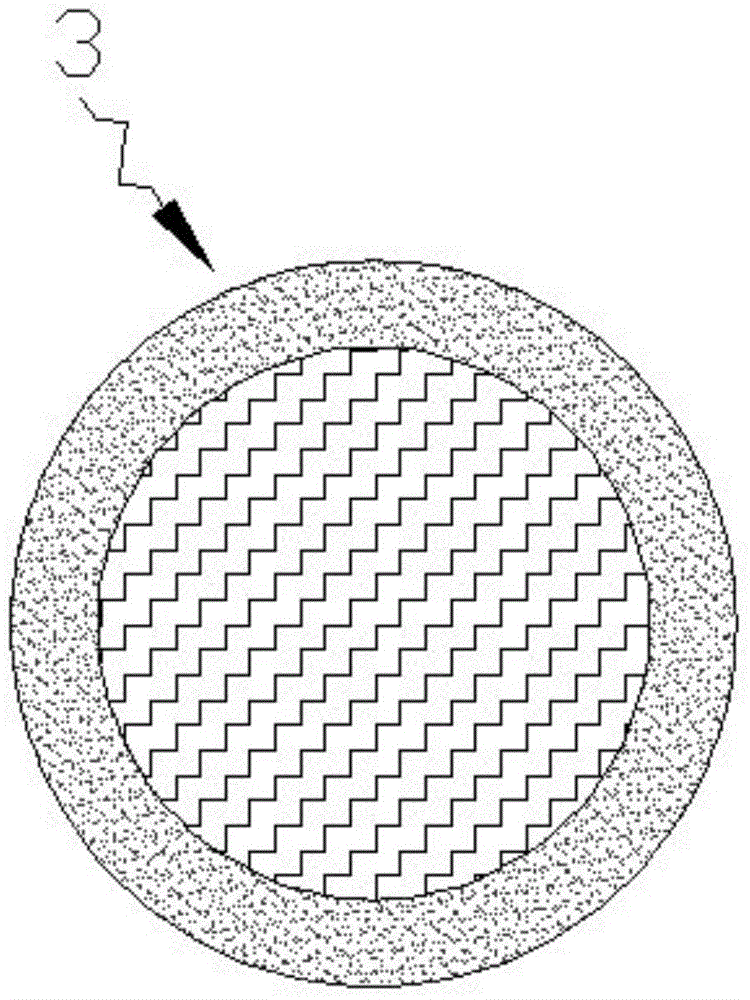

Image

Examples

Embodiment 1

[0052] 1. Manufacture the cutting wire A with a cutting wire diameter of 0.25mm according to the present invention. The core material alloy is composed of: copper: 84.0wt%, magnesium: 0.16wt%, boron: 0.012wt%, rare earth: 0.0012wt%, and the content of other elements is 0.5wt%, other elements are iron and phosphorus, the content of unavoidable impurity elements is less than 0.5wt%, and the rest is zinc; the surface metal is: copper: 37.0wt%, oxygen: 0.01-3.0wt%, magnesium: 0.09wt%, rare earth: 0.0006wt%, unavoidable impurity element content is less than 0.5%wt, and the rest is zinc.

[0053]Step 1. The raw materials are copper, magnesium and boron purchased in the market. After being selected and processed by the laboratory, after passing the test, the proportioning is carried out according to the requirements of the core material composition (wherein boron can be made into an intermediate alloy and added), and the prepared material is transported to The smelting site is smelte...

Embodiment 2

[0065] Manufacture the cutting wire B whose cutting wire diameter is 0.25mm according to the present invention, characterized by: copper: 81.0wt%, magnesium: 0.008wt%, boron: 0.009wt%, rare earth: 0.0017wt%, the content of other elements is 0.5wt%, Other elements are iron and phosphorus, the content of unavoidable impurity elements is less than 0.5wt%, and the rest is zinc; the surface metals are: copper: 39.0wt%, oxygen: 0.01-3.0wt%, magnesium: 0.004wt%, rare earth : 0.0008wt%, the content of unavoidable impurity elements is less than 0.5%wt, and the rest is zinc.

[0066] Step 1. The raw materials are copper, magnesium and boron purchased on the market. After testing and testing, they are selected and processed. After passing the test, the proportioning is carried out according to the requirements of the core material composition (wherein boron can be made into an intermediate alloy and added), and the prepared material is Transport to the smelting site for smelting, the sme...

Embodiment 3

[0078] 1. Manufacture the cutting wire C with a cutting wire diameter of 0.25mm in the present invention, characterized by: copper: 79.0wt%, magnesium: 0.008wt%, boron: 0.008wt%, rare earth: 0.01wt%, and the content of other elements is 0.5wt% %, other elements are iron and phosphorus, the content of unavoidable impurity elements is less than 0.5wt%, and the rest is zinc; the surface metal is: copper: 43.0wt%, oxygen: 0.0005-1.0wt%, magnesium: 0.004wt% , Rare earth: 0.005wt%, the content of unavoidable impurity elements is less than 0.5%wt, and the rest is zinc.

[0079] Step 1. The raw materials are copper, magnesium and boron purchased on the market. After testing and testing, they are selected and processed. After passing the test, the proportioning is carried out according to the requirements of the core material composition (wherein boron can be made into an intermediate alloy and added), and the prepared material is Transport to the smelting site for smelting, the smelti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com