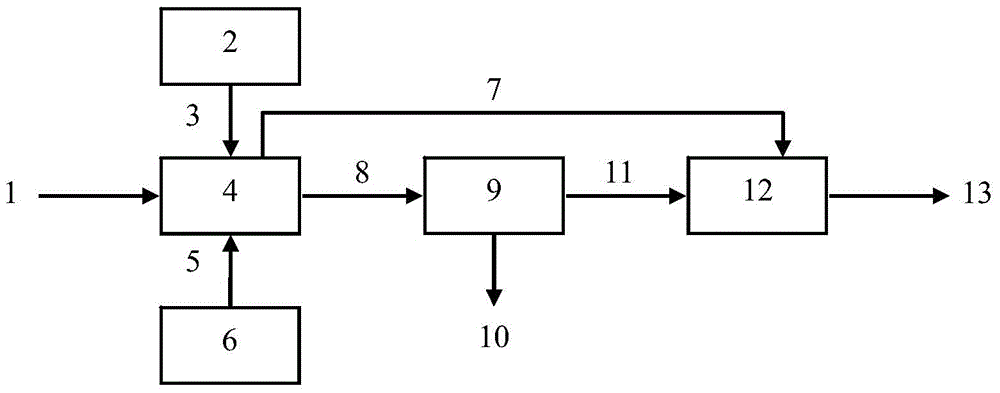

Device and method for synchronously removing ammonia nitrogen and sulfide of strong alkaline wastewater

A strong alkaline and sulfide technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of complex treatment process, increased treatment cost, increased energy consumption, etc., and achieve simple process route , reduce the accumulation of sulfide and ammonia nitrogen, and improve the effect of removing ammonia nitrogen and sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

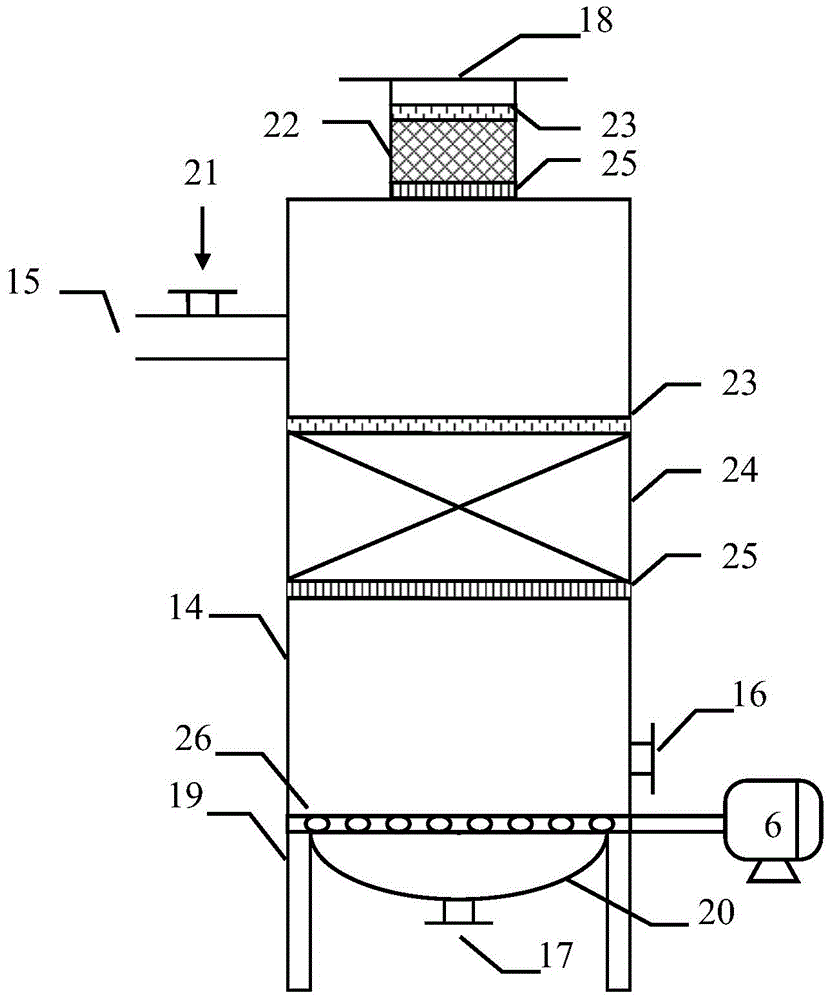

[0036] The strong alkaline ammonia nitrogen-containing and sulfide-containing wastewater 1 obtained after solid-liquid separation (pH value is 12.56, the content of sulfide is 90.5mg / L, the content of ammonia nitrogen is 100.5mg / L, and the temperature is 60°C) is sent to Into the reaction tower 4 (the volume of the reaction tower simulated under the laboratory conditions is 600mL, and the volume of the liquid added is 400mL; the reaction tower is a cylinder made of plexiglass, which has a water inlet, a water outlet, a slag outlet, and a gas outlet, etc.), Add catalyst 3 (catalyst comes from catalyst storage tank 2) from catalyst inlet 21 to reaction tower 4 while injecting water, and catalyzer is manganese sulfate, and the concentration of control manganese sulfate in reaction tower is 200mg / L, leaves standstill 15min. Then use air pump 6 to 0.250m 3 Air is continuously fed into the reaction tower at a rate of / h·L, and the air introduced is dispersed into the wastewater in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com