A normal temperature synthetic polycarboxylate high-performance water reducer and its preparation method

A synthetic polycarboxylic acid, high-performance technology, used in the field of room temperature synthetic polycarboxylic acid-based high-performance water reducer and preparation, can solve the problems of cumbersome production process, inefficient energy, unsafe, etc., to simplify the process, improve the Efficiency and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

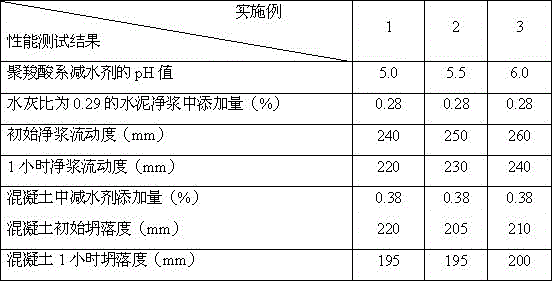

Examples

Embodiment 1

[0053] A room temperature synthetic polycarboxylate high-performance water reducer, composed of isopentenol polyoxyethylene ether 100, acrylic acid 10, methacrylic acid 0, propylene sulfonate sodium 0, methacrylic sodium sulfonate 0, hydrogen peroxide 1.1 , ammonium persulfate 0.5, L-ascorbic acid 0.16, sodium dithionite 0.16, thioglycolic acid 0, mercaptopropionic acid 0, sodium hydroxide 10 and water 110.

[0054] The synthesis steps of the water reducer are as follows:

[0055] (1) Take isopentenol polyoxyethylene ether, acrylic acid, methacrylic acid, sodium propylene sulfonate, sodium methacrylate sulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, sodium dithionite, Thioglycolic Acid, Mercaptopropionic Acid, Sodium Hydroxide and Water.

[0056](2) Put isopentenol polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium propylene sulfonate, sodium methacrylate sulfonate and water accounting for 20% of the total water consumption into the poly...

Embodiment 2

[0062] A room temperature synthetic polycarboxylate high-performance water reducer, composed of 100 prenol polyoxyethylene ether, 15 acrylic acid, 3 methacrylic acid, 3 propylene sulfonate sodium, methacrylic sodium sulfonate 3, hydrogen peroxide 1.6 , ammonium persulfate 2.0, L-ascorbic acid 0.20, sodium dithionite 0.23, mercaptoacetic acid 0.3, mercaptopropionic acid 0.2, sodium hydroxide 14 and water 150.

[0063] The synthesis steps of the water reducer are as follows:

[0064] (1) Take isopentenol polyoxyethylene ether, acrylic acid, methacrylic acid, sodium propylene sulfonate, sodium methacrylate sulfonate, hydrogen peroxide, ammonium persulfate, L-ascorbic acid, sodium dithionite, Thioglycolic Acid, Mercaptopropionic Acid, Sodium Hydroxide and Water.

[0065] (2) Put isopentenol polyoxyethylene ether, hydrogen peroxide, ammonium persulfate, sodium propylene sulfonate, sodium methacrylate sulfonate and water accounting for 20% of the total water consumption into the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com