Short SiC fiber/SiO2 aerogel composite material and preparation method thereof

A technology of silicon carbide fiber and composite material, which is applied in the field of short silicon carbide fiber/SiO2 airgel composite material and its preparation, can solve the problems of poor high temperature stability, low airgel strength, and high cost, and achieve low cost and thermal conductivity The effect of low coefficient and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

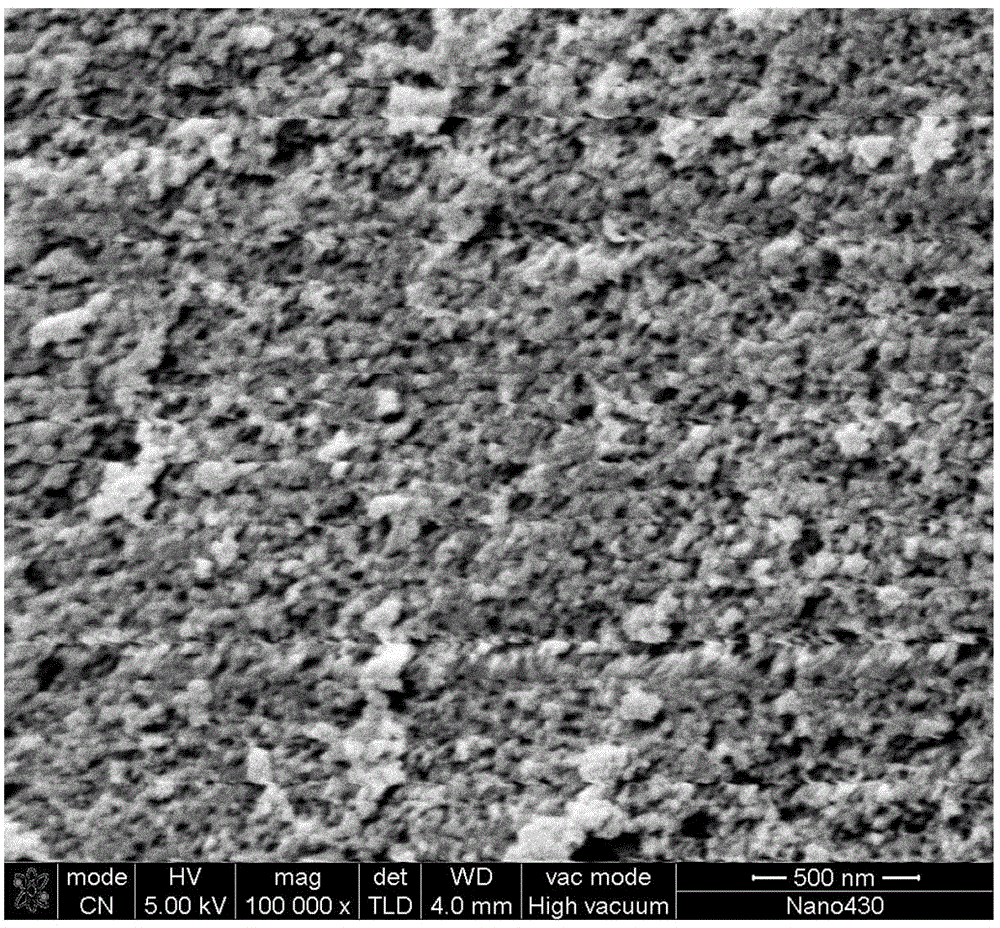

Embodiment 1

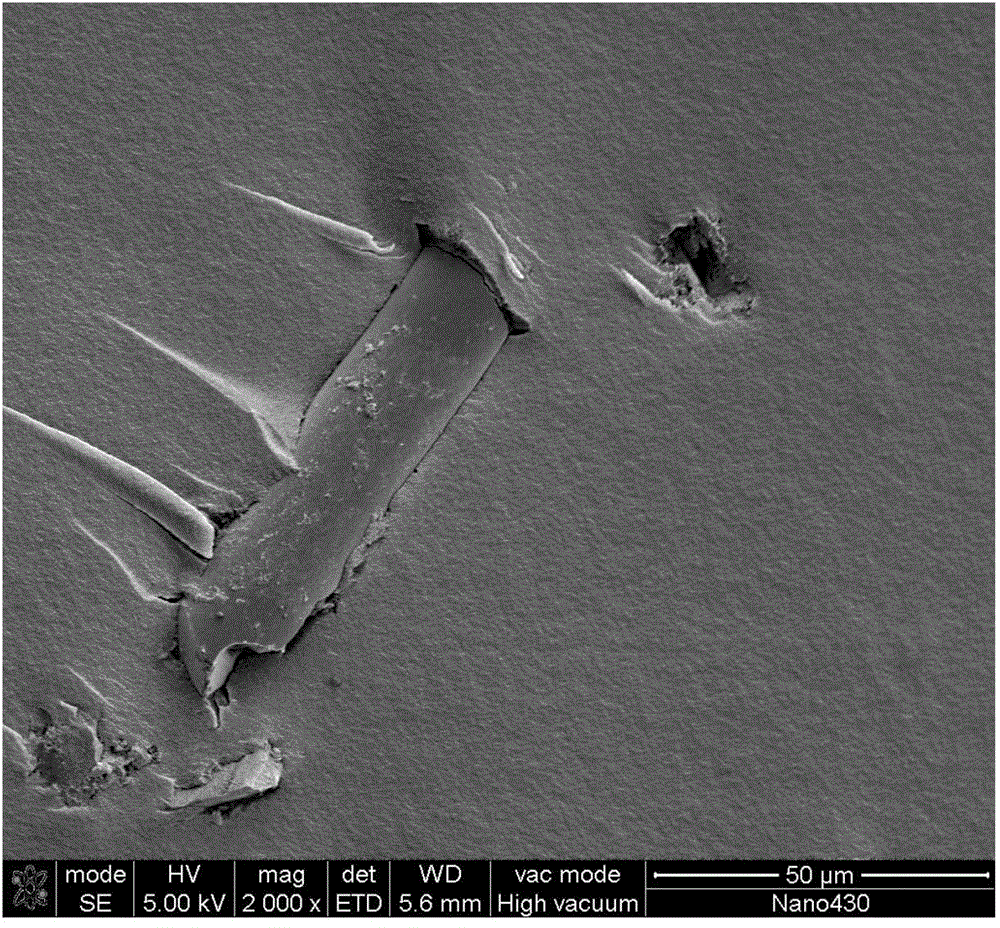

[0021] 1) Cut and grind long SiC fibers into short fibers with a diameter of 8-15um and a length of less than 1mm;

[0022] 2) Mix silica sol, ethanol, water and hexamethyldisiloxane in a molar ratio of 1:4:6:0.05 and stir evenly, add 0.5mol / l hydrochloric acid to adjust the pH to 2.5, stir for 20min, then add 0.1 mol / l ammonia water, adjust the pH to 5.0, stir for 60 min, and mix evenly to obtain a silica sol.

[0023] 3), get the short SiC fiber in step 1) (accounting for SiO 2 The mass percentage of sol is 5%) adding SiO 2 The sol was mixed and stirred evenly, and after standing for 9 minutes, the gel was aged, and the surface was modified (hexamethyldisiloxane modifier) and solvent exchanged with ethylene glycol and methanol (each 24 hours).

[0024] 4) Drying under normal pressure at 60°C (2h) and 80°C (2h) respectively to obtain short SiC fiber-composite silica airgel composite materials.

[0025] After testing, it was found that the density of the material is 0.2g / ...

Embodiment 2

[0027] 1) Cut and grind long SiC fibers into short fibers with a diameter of 8-15um and a length of less than 1mm;

[0028] 2) Mix silica sol, ethanol, water and hexamethyldisiloxane in a molar ratio of 1:2:8:0.03 and stir evenly, add 0.5mol / l hydrochloric acid to adjust the pH to 3.0, stir for 25min, then add 0.1 mol / l ammonia water, adjust the pH to 5.5, stir for 50 minutes, and mix evenly to obtain a silica sol.

[0029] 3), get the short SiC fiber in step 1) (accounting for SiO 2 The mass percent of sol is 8%) adding SiO 2 The sol was mixed and stirred evenly, and after standing for 8 minutes, the gel was aged, and the surface was modified (hexamethyldisiloxane modifier) and solvent exchanged with ethylene glycol and methanol (each 24 hours).

[0030] 4) Drying under normal pressure at 60°C (2h), 80°C (2h), and 100°C (2h) respectively to obtain short SiC fiber-composite silica airgel composite materials.

[0031] After testing, it was found that the specific surface a...

Embodiment 3

[0033] 1) Cut and grind long SiC fibers into short fibers with a diameter of 8-15um and a length of less than 1mm;

[0034] 2) Mix silica sol, ethanol, water and hexamethyldisiloxane in a molar ratio of 1:6:6:0.04 and stir evenly, add 0.5mol / l hydrochloric acid to adjust the pH to 3.5, stir for 25min, then add 0.1mol / l ammonia water, adjust the pH to 6.5, stir for 50min, and mix evenly to obtain a silica sol.

[0035] 3), get the short SiC fiber in step 1) (accounting for SiO 2 The mass percent of sol is 10%) adding SiO 2 The sol was mixed and stirred evenly, and after standing for 7 minutes, the gel was aged, and the surface was modified (hexamethyldisiloxane modifier) and solvent exchanged with ethylene glycol and methanol (each 24 hours).

[0036] 4) Drying under normal pressure at 60°C (2h) and 80°C (4h) respectively to obtain short SiC fiber-composite silica airgel composite materials.

[0037] After testing, it was found that the specific surface area of the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| High temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com