Plant transplanting nutrient paper and preparation method thereof

A plant nutrient solution and nutrient paper technology, which is applied in the field of plant transplantation, can solve the problems of poor sustainability of nutrient solution input and poor biodegradability of polymer hanging needle bags, and achieve good sustainability and high survival rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

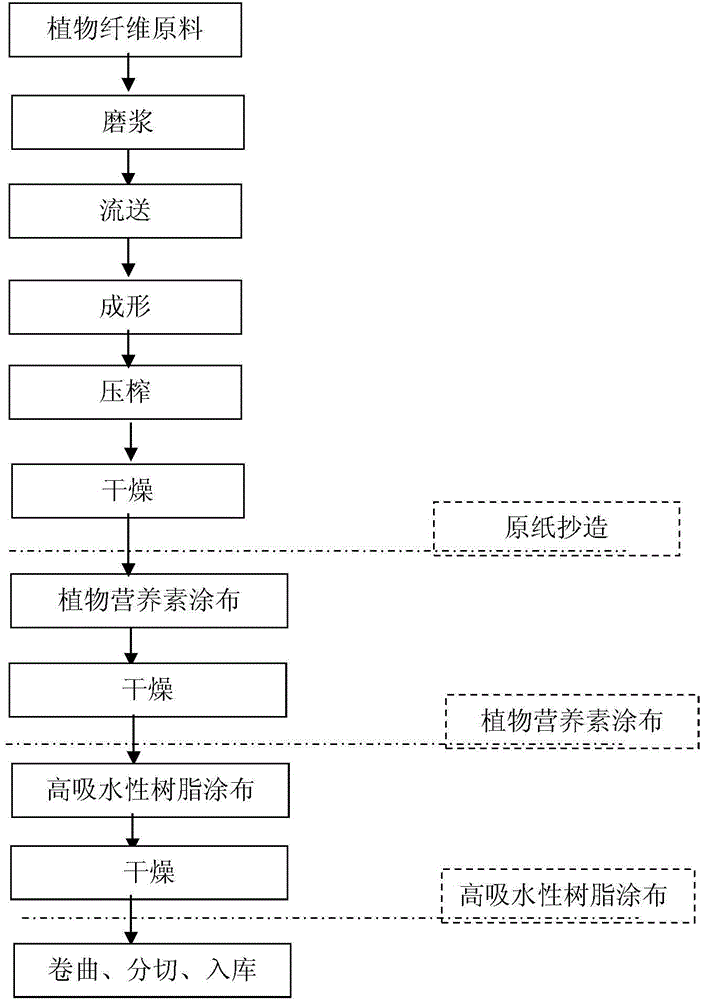

Method used

Image

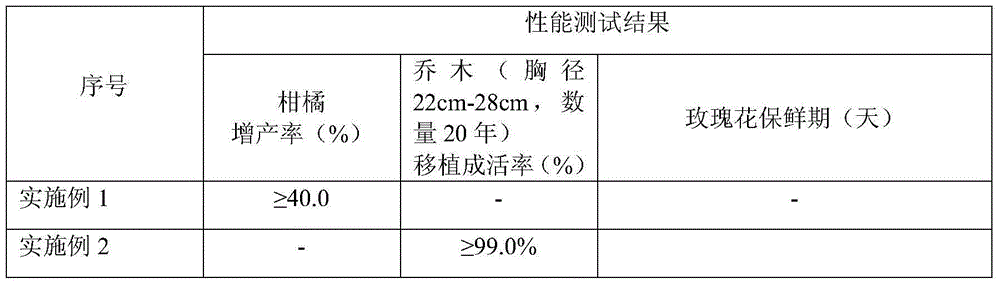

Examples

Embodiment 1

[0027] (1) Use chemical pulp and waste paper pulp to make fiber paper, the air permeability of the finished paper is 4.5μm / Pa·s; the bursting index is 2.4kpa·m 2 / g; wet tensile strength 0.32kN / m; quantitative 60g / m 2 ;

[0028] (2) Coating the fiber paper in step (1) with plant nutrient solution, the impregnating solution formula is 8 parts of nutrients such as urea, ammonium sulfate, potassium sulfate, manganese sulfate, magnesium sulfate, ferrous sulfate, copper sulfate, zinc sulfate , 1 part of fungicide, 1 part of anti-water agent, dry.

[0029] (3) Spray the fiber paper impregnated with nutrient solution in step (2) with 30g / m of superabsorbent resin 2 , The superabsorbent coating contains 100 parts of cellulose-modified hydrogel-polyacrylamide, 2 parts of dispersant; 12 parts of adhesive (starch: carboxylated styrene-butadiene latex=2:5), 2 parts of bactericide and 3 parts of water-resistant agent ,dry.

Embodiment 2

[0031] (1) Use chemical pulp and waste paper pulp to make fiber paper, the air permeability of the finished paper is 4.8μm / Pa·s; the bursting index is 2.5kpa·m 2 / g; wet tensile strength 0.30kN / m; quantitative 60g / m 2 ;

[0032] (2) Firstly, the fiber paper in step (1) is coated with 20g / m of phytonutrients 2 , The coating formula includes 100 parts of pigment (light calcium carbonate: diatomaceous earth: bentonite = 80:10:10), 10 parts of adhesive (starch: carboxylated styrene-butadiene latex = 2:5), urea, superphosphate, 10 parts of nutrients such as manganese sulfate, ferrous sulfate, copper sulfate, zinc sulfate, etc., 3 parts of dispersant, 1 part of fungicide, 1 part of anti-water agent, dry.

[0033] (3) Spray the fiber paper impregnated with nutrient solution in step (2) with 20g / m of superabsorbent resin 2 , The superabsorbent coating contains 100 parts of cellulose-modified hydrogel-polyacrylamide, 2 parts of dispersant; 12 parts of adhesive (starch: carboxylated ...

Embodiment 3

[0035](1) Use chemical pulp and waste paper pulp to make fiber paper, the air permeability of the finished paper is 5.2μm / Pa·s; the bursting index is 3.0kpa·m 2 / g; wet tensile strength 0.50kN / m; quantitative 45g / m 2 ;

[0036] (2) Spray the fiber paper in step (1) with superabsorbent resin 15g / m 2 , the superabsorbent coating contains cellulose modified hydrogel, hemicellulose modified hydrogel, 100 parts of polyacrylamide, 3 parts of dispersant; 10 parts of adhesive (starch: carboxylated styrene-butadiene latex=5:5), 1 part of fungicide and 5 parts of anti-water agent, dry.

[0037] (3) Firstly, the fiber paper base in step (2) is coated with 20g / m of phytonutrients 2 , The coating formula includes 100 parts of pigment (light calcium carbonate: diatomaceous earth: bentonite = 80:10:10), 10 parts of adhesive (starch: carboxylated styrene-butadiene latex = 2:5), urea, superphosphate, Potassium chloride, copper sulfate, zinc sulfate and other nutrients 1 part, dispersant 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com