A non-parallel plate capacitively coupled plasma chemical vapor deposition method

A capacitive coupling and plasma technology, which is applied in the field of non-parallel plate capacitively coupled plasma chemical vapor deposition, can solve problems such as film defects and substrate damage, and achieve the effects of improving quality, reducing surface damage, and suppressing bombardment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

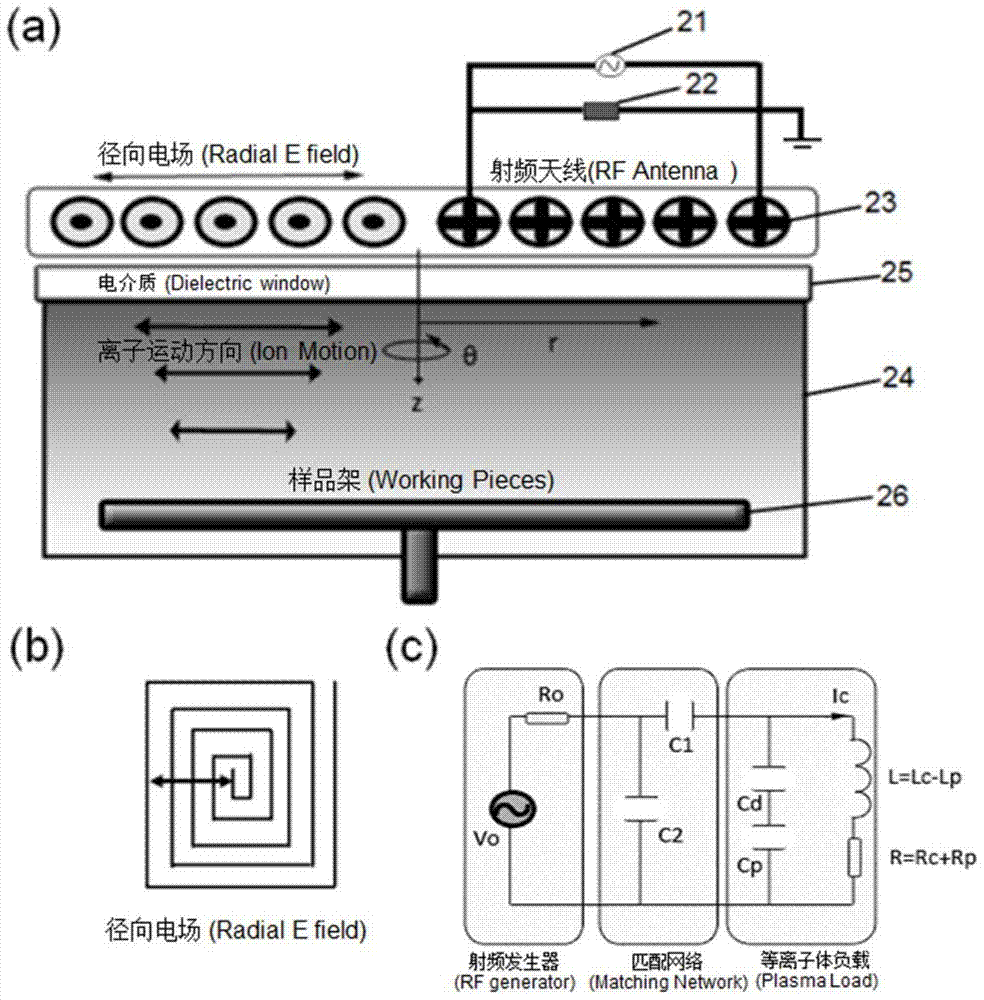

[0020] First of all, for the convenience of explanation, we define the positive z-axis direction passing through the center of the plane spiral coil and perpendicular to the downward direction of the coil, and define the r-direction as the direction perpendicular to the Z-axis. exist figure 2 In (a), when the planar coil 23 is injected with a lower frequency (500kHz) current by the radio frequency generator 21, there are two different electric fields in the discharge space at the same time, which are radial electrostatic fields ( Capacitive coupling) and the eddy electric field (inductive coupling) generated by the change of the magnetic field in the discharge space. In the non-parallel plate capacitively coupled plasma discharge mode, the RF input power is lower, resulting in lower coil current and thicker plasma shell, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com