Preparation method of TiAlSiN and CrAlSiN nano composite coating

A nano-composite coating and substrate technology, which is applied in the coating, metal material coating process, ion implantation plating, etc., can solve the problems of high temperature friction coefficient of TiAlN coating, coating mechanics, wear resistance decline, cutting tool cutting, etc. To solve problems such as large force, achieve the effects of excellent solid solution grains, excellent high temperature stability, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

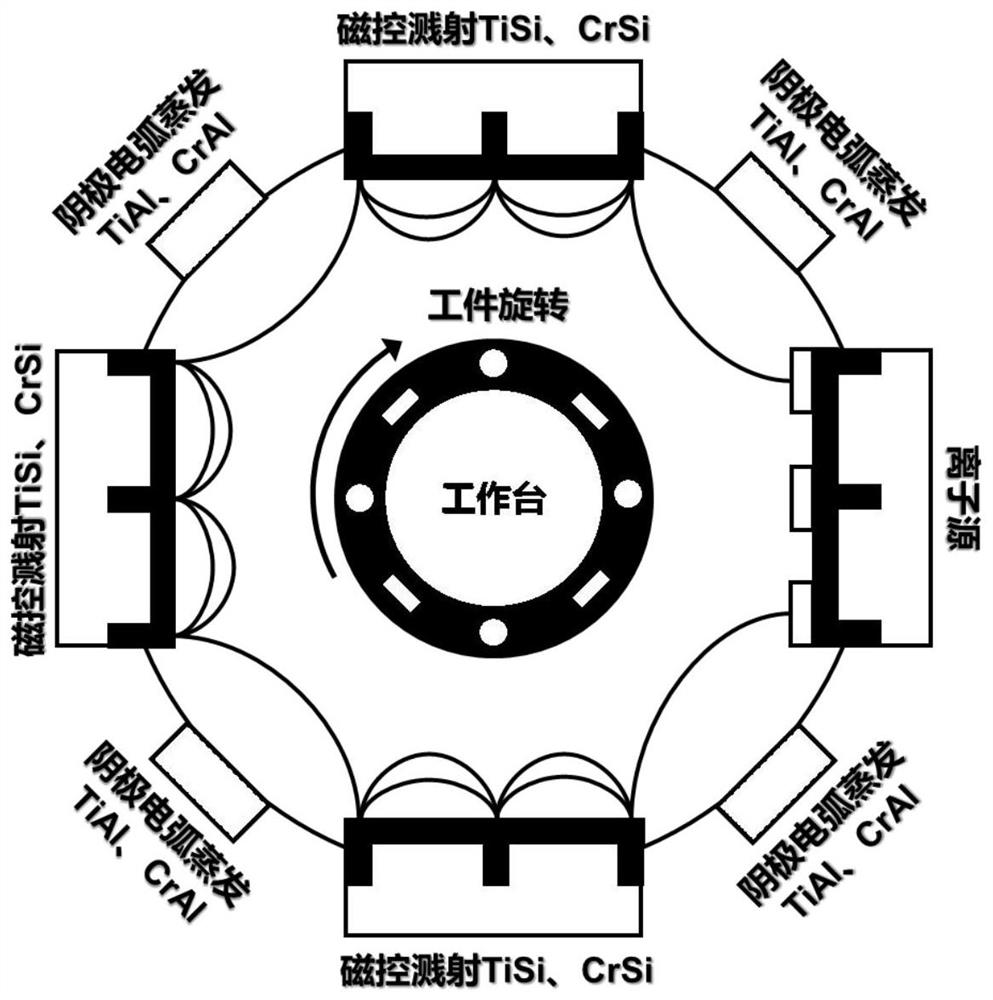

[0025] A preparation method of TiAlSiN, CrAlSiN nano composite coating, comprising the following steps:

[0026] S1: mechanically grinding, polishing and cleaning the WC-Co substrate;

[0027] S2: Using a magnetron sputtering power supply, sputter TiSi and CrSi targets in front of the WC-Co substrate; at the same time, use a cathodic arc evaporation power supply to arc evaporate TiAl and CrAl targets in front of the WC-Co substrate.

[0028] In step S2, the magnetron sputtering power supply sputters TiSi and CrSi targets, and the Si atomic ratio content in the target is 50%-100%; in step S2, the target average power density of the magnetron sputtering TiSi and CrSi targets is 5 -20 W / cm 2; In step S2, the cathodic arc evaporation power supply evaporates TiAl and CrAl targets, and the Al atomic ratio content in the target is 0-70%; in step S2, the average target current density of the cathodic arc evaporation TiAl and CrAl targets is 0.5-2A / cm 2 ; In step S2, the temperature ...

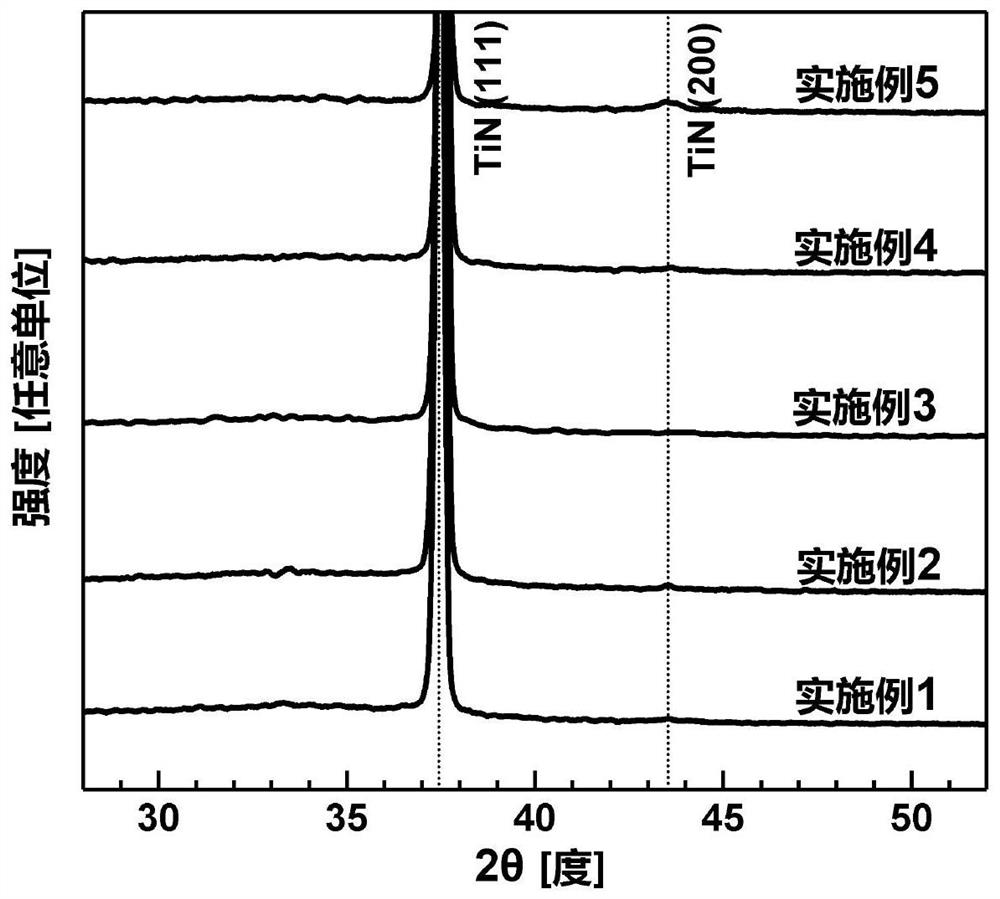

Embodiment 1

[0030] Substrate pretreatment

[0031] (1) Mechanically grinding and polishing the WC-Co substrate;

[0032] (2) Solvent cleaning treatment; first use isopropanol to ultrasonically clean for 10 minutes, then use 98% alcohol solution to ultrasonically clean for 10 minutes, take it out, and then use ultrapure water to ultrasonically clean for 3 minutes;

[0033] (3) Glow cleaning treatment: Ar gas ion source was used to clean the substrate for 30 minutes, the ambient pressure was 0.1Pa; the bias voltage of the substrate was -800V, and the frequency was 240kHz.

[0034] TiAlSiN nanocomposite coating prepared by magnetron sputtering and cathodic arc evaporation;

[0035] (1) Use the magnetron sputtering power supply to sputter the Ti50Si50 target in front of the substrate; at the same time use the cathodic arc evaporation power supply to arc evaporate the TiSi target in front of the substrate;

[0036] (2) The average power density of the magnetron sputtering Ti50Si50 target is ...

Embodiment 2

[0038] Preparation of TiAlSiN Nanocomposite Coatings by Magnetron Sputtering and Cathodic Arc Evaporation

[0039] (1) Use the magnetron sputtering power supply to sputter the Ti50Si50 target in front of the substrate; at the same time use the cathodic arc evaporation power supply to arc evaporate the TiSi target in front of the substrate;

[0040] (2) The average power density of the magnetron sputtering Ti50Si50 target is 20W / cm 2 , the average target current density of cathodic arc evaporation Ti target is 2A / cm 2 ; During the film deposition process, the substrate temperature was maintained at 600 °C, the working gas was introduced, the deposition chamber pressure was adjusted to 2.0Pa, the substrate was loaded with a negative bias voltage of -150V, and the TiAlSiN coating was deposited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com