Anti-theft door decorated with thin wood veneer line frame and its production process

A production process and anti-theft door technology, which is applied in the field of doors and windows, can solve the problems of not being able to create high-end natural solid wood effects, steel-wood armored doors are easy to warp and deform, and density boards are easy to absorb moisture and expand and deform, so as to achieve good color and reduce manufacturing costs , The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

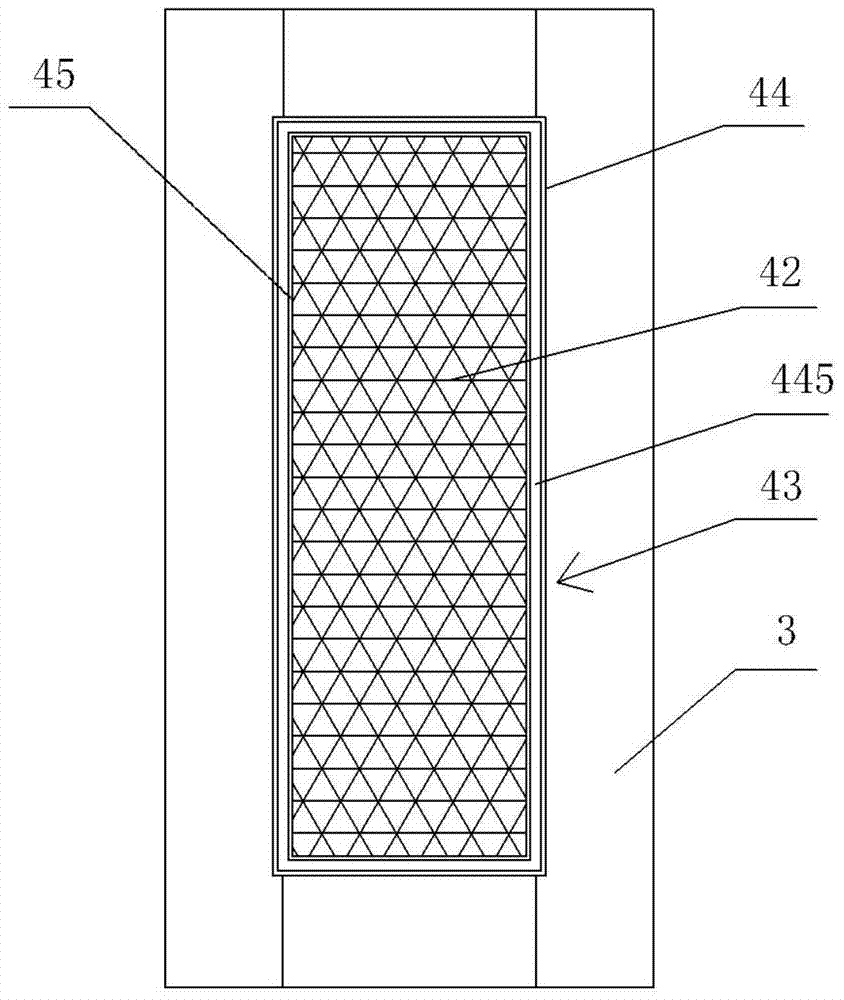

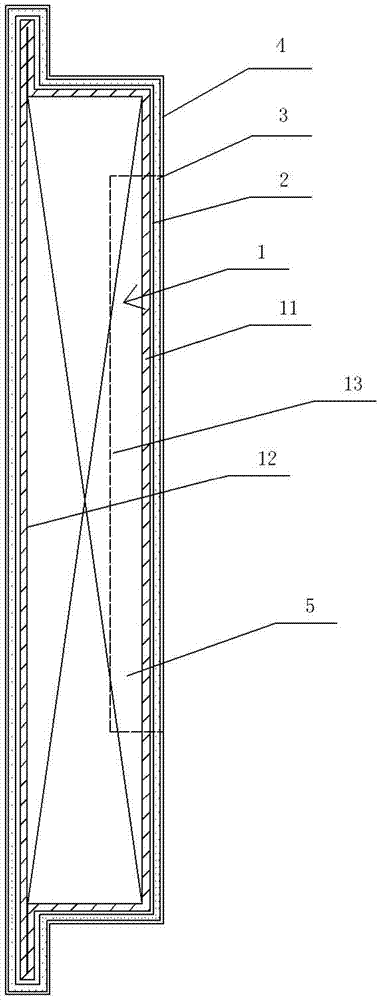

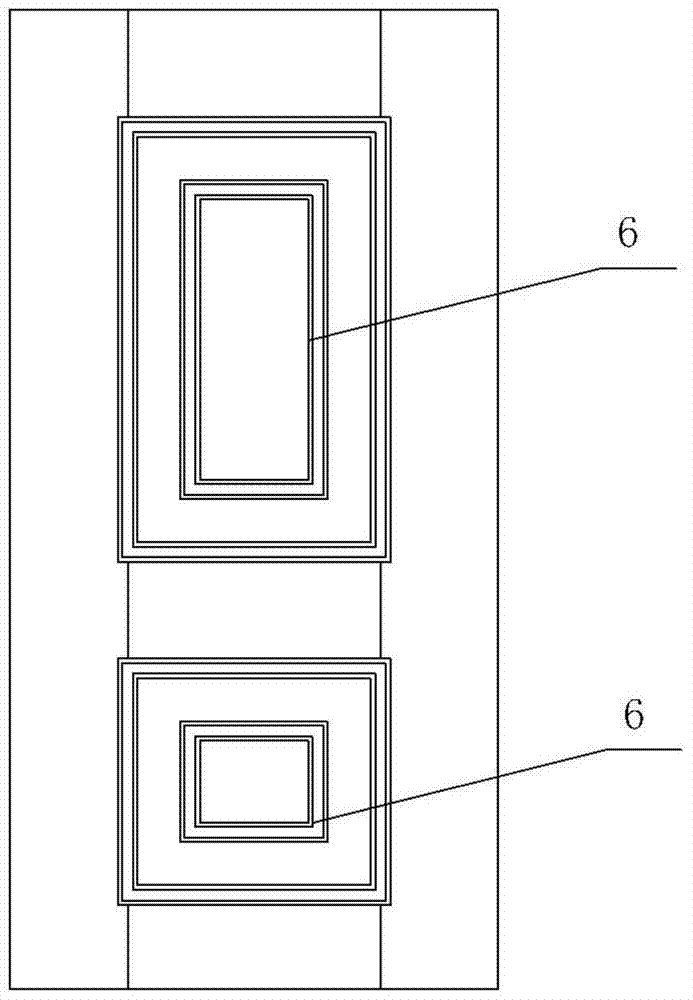

[0037] Such as figure 1 , 2 . As shown in 3, the anti-theft door is decorated with a thin wood veneer line frame, including a facade 1, and the facade is made of a steel plate. The steel plate can make the facade have strong rigidity, and at the same time reduce the wood required by the general facade. The door includes a front door 11 and a back door 12, and a filling material 13 for filling the inside is added between the front door and the back door. The surface of the facade is bonded with natural veneer 3 or recombined decorative veneer through the glue layer 2, the glue layer is composed of adhesive, the adhesive is one of PUR glue, universal glue, epoxy resin glue, polyurethane glue, and the adhesive is PUR glue. Glue; use outdoor wood wax oil, weather-resistant PU paint, weather-resistant water-based paint, and fluorocarbon paint to obtain better light fastness grades.

[0038]Natural veneer surface coated with paint layer 4. The natural veneer includes several nat...

Embodiment 2

[0051] Such as figure 1 , 2 As shown in , 4, the anti-theft door is decorated with a thin wood veneer line frame, including a facade 1, and the facade is made of a steel plate. The steel plate can make the facade have strong rigidity, and at the same time reduce the wood required by the general facade. The door surface comprises a front door surface 11 and a rear door surface 12, and a filling material 13 for filling the inside is added between the front door surface and the back door surface. The surface of the facade is bonded with natural veneer 3 or recombined decorative veneer through the glue layer 2, the glue layer is composed of adhesive, the adhesive is one of PUR glue, universal glue, epoxy resin glue, polyurethane glue, and the adhesive is PUR glue. Glue; use outdoor wood wax oil, weather-resistant PU paint, weather-resistant water-based paint, and fluorocarbon paint to obtain better light fastness grades.

[0052] Natural veneer surface coated with paint layer 4...

Embodiment 3

[0064] Such as figure 1 , 2 As shown in , 3, the anti-theft door is decorated with a thin wood veneer line frame, including a facade 1, and the facade is made of a steel plate. The steel plate can make the facade have strong rigidity, and at the same time reduce the wood required by the general facade. The door surface comprises a front door surface 11 and a rear door surface 12, and a filling material 13 for filling the inside is added between the front door surface and the back door surface. The surface of the facade is bonded with natural veneer 3 or recombined decorative veneer through the glue layer 2, the glue layer is composed of adhesive, the adhesive is one of PUR glue, universal glue, epoxy resin glue, polyurethane glue, and the adhesive is PUR glue. Glue; use outdoor wood wax oil, weather-resistant PU paint, weather-resistant water-based paint, and fluorocarbon paint to obtain better light fastness grades.

[0065] Natural veneer surface coated with paint layer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com