Formamide preparation method

A formamide and dimethylformamide technology, applied in the field of formamide preparation, can solve the problems of complex catalyst preparation process, easy catalyst deactivation, low reaction yield, etc., and achieve high controllability, conversion rate and selectivity High, simple reaction process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

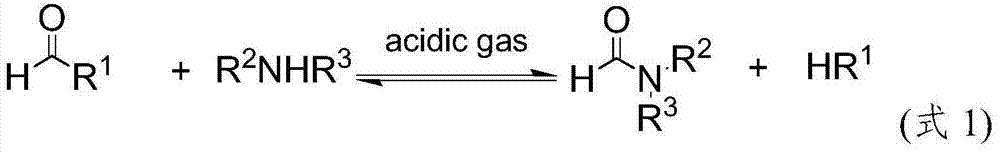

AI Technical Summary

Problems solved by technology

Method used

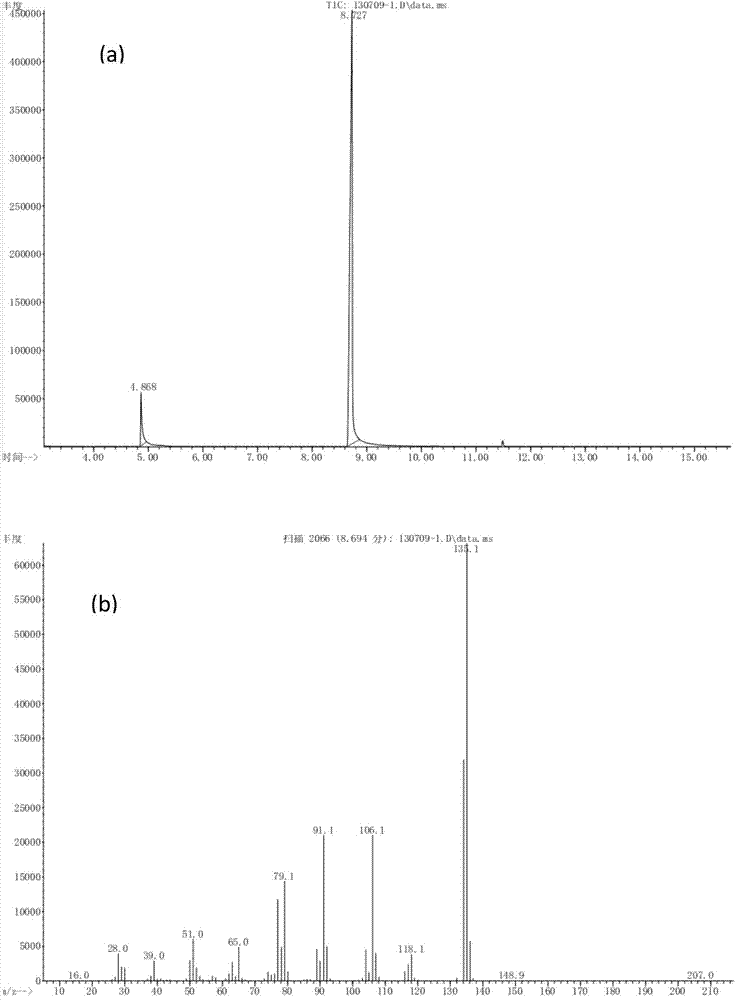

Image

Examples

Embodiment 1

[0024] In a 150ml pressure bottle, add 15mmol benzylamine and 20ml N,N-dimethylformamide respectively, and use CO 2 After gas replacement, the reaction was stirred at 100°C for 12 hours. After the reaction, the product was detected by chromatography. The conversion rate and selectivity are shown in Table 1.

Embodiment 2

[0026] In a 150ml polytetrafluoroethylene lined reactor, add 15mmol n-butylamine and 20ml formamide respectively, and charge CO 2 , The pressure is 0.6MPa. The reaction was stirred at 120°C for 12 hours. After the reaction, the product was detected by chromatography. The conversion rate and selectivity are shown in Table 1.

Embodiment 3

[0028] In a 150ml polytetrafluoroethylene-lined reactor, add 15mmol benzylamine and 20ml N,N-diethylformamide, and charge CO 2 , The pressure is 0.2MPa, and the reaction is stirred at 80°C for 24h. After the reaction is completed, the product is detected by chromatography. The conversion rate and selectivity are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com