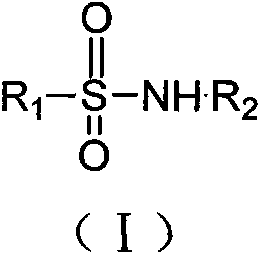

Sulfamide benzylation method

A technology of sulfonamide benzyl and sulfonamide, applied in the field of organic chemical synthesis, can solve the problems of unfavorable industrial production, high reaction temperature, high production cost, etc., and achieve the effects of convenient industrial production, high yield and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

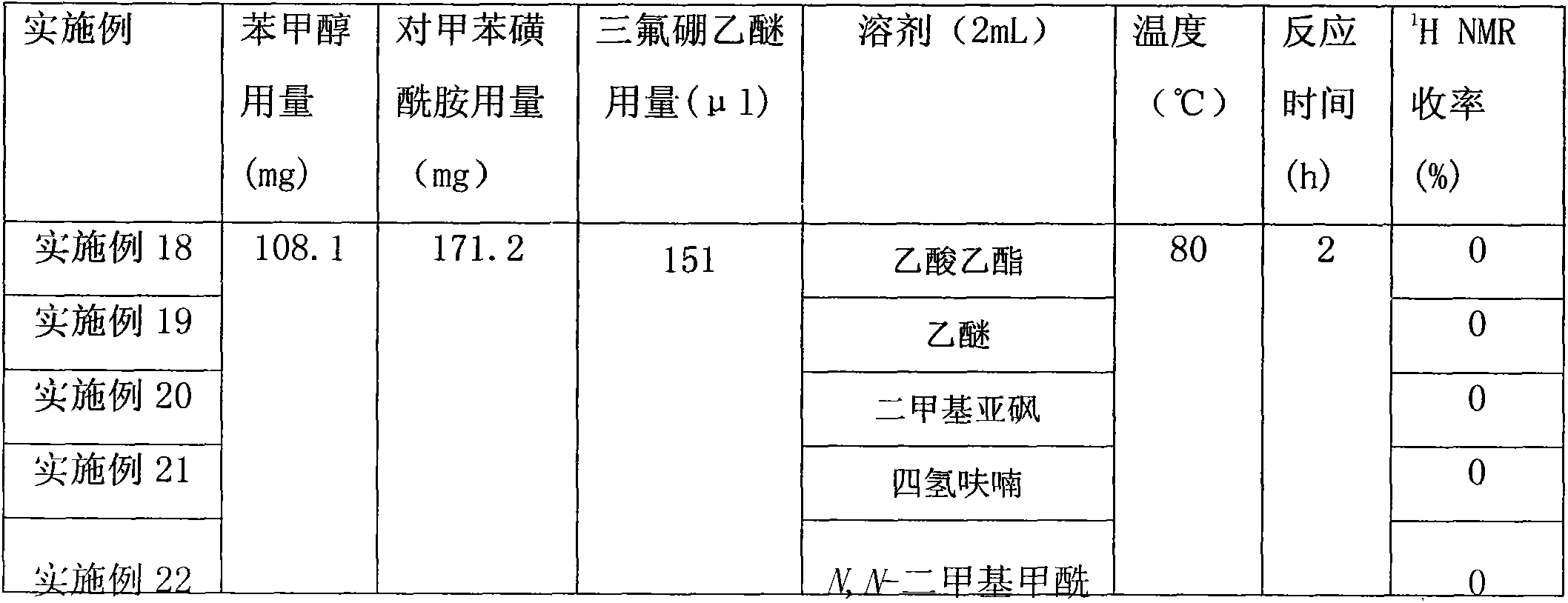

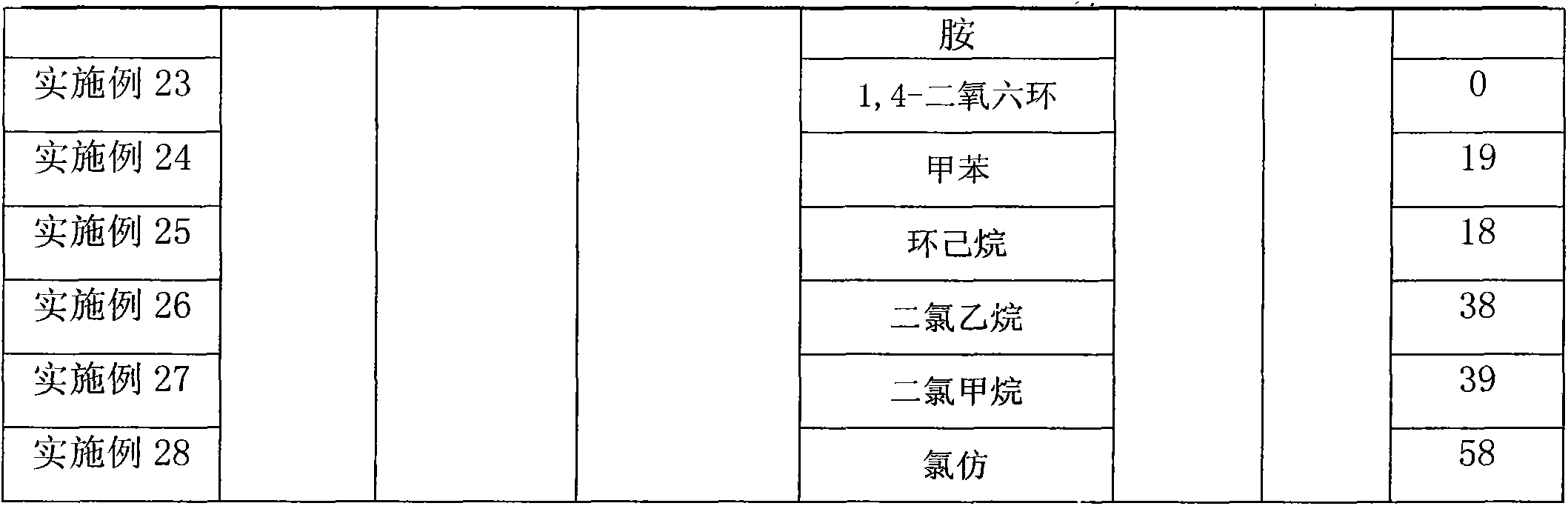

Examples

Embodiment 1

[0024] A kind of method of sulfonamide benzylation, its concrete steps are as follows:

[0025] (1) Taking benzyl alcohol and p-toluenesulfonamide as raw materials, boron trifluoride ether as a reagent, and chloroform as a solvent, according to the millimoles of benzyl alcohol: millimoles of p-toluenesulfonamide: BF 3 ·OEt 2 The ratio of millimole: chloroform milliliter is 1: 1.8: 1.2: 2, add benzyl alcohol (108.1mg, 1.0mmol), p-toluenesulfonamide (308.2mg, 1.8mmol) and trichloromethane successively in the reactor Methane (2.0mL), under stirring, added BF 3 ·OEt 2 (151 μL, 1.2 mmol), after the addition was complete, the stirring reaction was continued at 80° C. for 2 hours.

[0026] (2) After step (1) is completed, the reaction solution of benzylsulfonamide prepared in step (1) is concentrated by rotary evaporation, and the concentrated solution is collected; the concentrated solution is purified by silica gel column chromatography, and the eluent After elution, the efflue...

Embodiment 2

[0029] A kind of method of sulfonamide benzylation, its concrete steps are with embodiment 1, wherein:

[0030] In step (1), take benzyl alcohol and benzenesulfonamide as raw materials, boron trifluoride ether is reaction reagent, and chloroform is made solvent, according to benzyl alcohol mmol: benzenesulfonamide mmol: BF 3 ·OEt 2 Millimoles: The ratio of chloroform milliliters is 1:1.8:1.2:2 ratio, successively add benzyl alcohol (108.1mg, 1.0mmol), benzenesulfonamide (282.9mg, 1.8mmol) and chloroform in the reactor (2.0mL), under stirring, add BF 3 ·OEt 2 (151 μL, 1.2 mmol), after the addition was complete, the stirring reaction was continued at 80° C. for 2 hours.

[0031] In step (2), the eluent was a mixture of ethyl acetate:petroleum ether with a volume ratio of 1:(2-40), and N-benzylbenzenesulfonamide (171 mg, yield 69%) was obtained as a white solid.

Embodiment 3

[0033] A kind of method of sulfonamide benzylation, its concrete steps are with embodiment 1, wherein:

[0034] In step (1), benzyl alcohol and methanesulfonamide are used as raw materials, boron trifluoride ether is a reagent, and chloroform is used as a solvent. 3 ·OEt 2 The ratio of millimoles: chloroform milliliters is 1: 1.8: 1.2: 2, successively add benzyl alcohol (108.1mg, 1.0mmol), methanesulfonamide (171.2mg, 1.8mmol) and chloroform in the reactor (2.0mL), under stirring, add BF 3 ·OEt 2 (151 μL, 1.2 mmol), after the addition was complete, the stirring reaction was continued at 80° C. for 2 hours.

[0035] In step (2), the eluent was a mixture of ethyl acetate:petroleum ether with a volume ratio of 1:(2-40), and N-benzylmethanesulfonamide (144 mg, yield 78%) was obtained as a white solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com