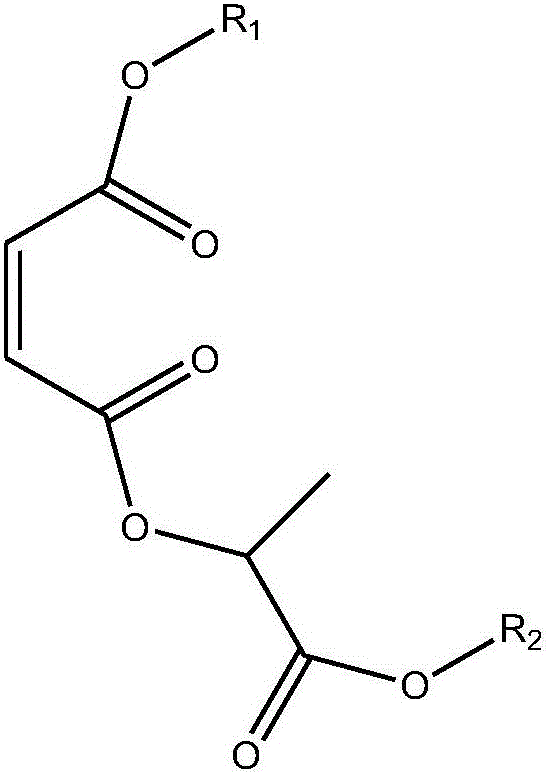

O-maleoyl lactylate compound, its preparation method and its application in the synthesis of polycarboxylate superplasticizer

An acyl lactylate and compound technology, applied to O-maleyl lactate compound and its preparation and application in the synthesis of polycarboxylate water reducer, can solve the problem of poor initial dispersibility, cumbersome process, excessive cement Compatibility of retarded cement and retarder, etc., to achieve the effects of increased concrete slump, cheap and easy-to-obtain synthetic raw materials, and good initial dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Weigh methyl lactate (104 g, 1 mol) and maleic anhydride (98 g, 1 mol) respectively, place them in a reaction kettle, add 1 g of p-toluenesulfonic acid, and stir well. Under the protection of nitrogen, the reaction system was slowly heated to 80° C. and stirred for 2-4 h until the reaction was complete (the reaction can be monitored by GC or TLC). After cooling, the light yellow solid product O-methyl maleyl lactylate (1) is obtained, which can be directly used in the synthesis of polycarboxylate water reducer mother liquor without separation and purification.

Embodiment 2

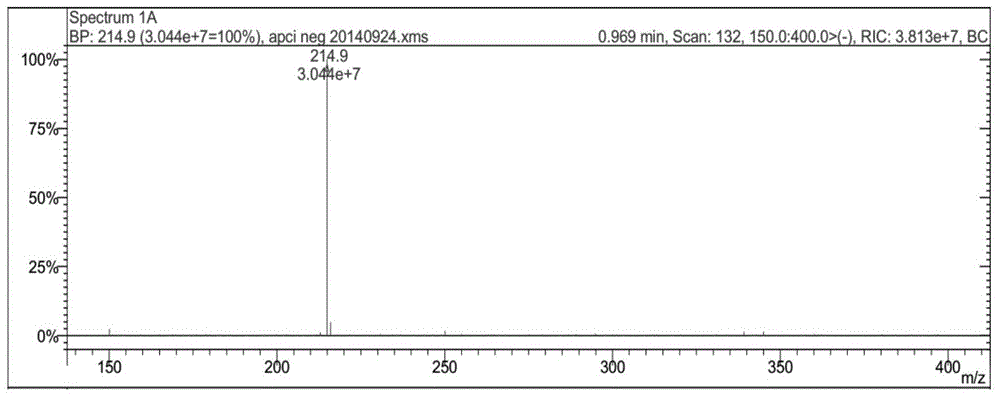

[0049] Add methyl lactate (104 g, 1 mol) and maleic anhydride (98 g, 1 mol) into chloroform (500 mL) respectively, stir and dissolve at room temperature, and then add 1 g of p-toluenesulfonic acid. Under the protection of nitrogen, the reaction system is slowly heated to reflux, and the reaction progress can be monitored by GC or TLC, etc., and the reflux reaction is kept for 2-4 hours until the reaction is complete. After cooling, the solvent was distilled off to obtain the light yellow solid product O-methyl maleyl lactylate (1), which can be used for the synthesis of polycarboxylate water reducer mother liquor without separation and purification. ESI-MS(m / z):[M-H] - 201.1.

Embodiment 3

[0051] Ethyl lactate (118g, 1mol) and maleic anhydride (98g, 1mol) were weighed separately, placed in a reaction kettle, 1g of p-toluenesulfonic acid was added, and stirred evenly. Under the protection of nitrogen, the reaction system was slowly heated to 80° C. and stirred for 2-4 h until the reaction was complete (the reaction can be monitored by GC or TLC). After cooling, the light yellow solid product O-ethyl maleyl lactate (2) can be obtained, which can be directly used in the synthesis of polycarboxylate superplasticizer mother liquor without separation and purification. ESI-MS(m / z):[M-H] - 215.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com