High molecular weight (HMW) pleurotus eryngii polysaccharide and preparation method thereof

A technology of polymer and Pleurotus eryngii leftovers, which is applied in the field of extraction of active ingredients of edible fungi, can solve problems such as less research, and achieve the effects of simple process, reduced environmental pollution, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

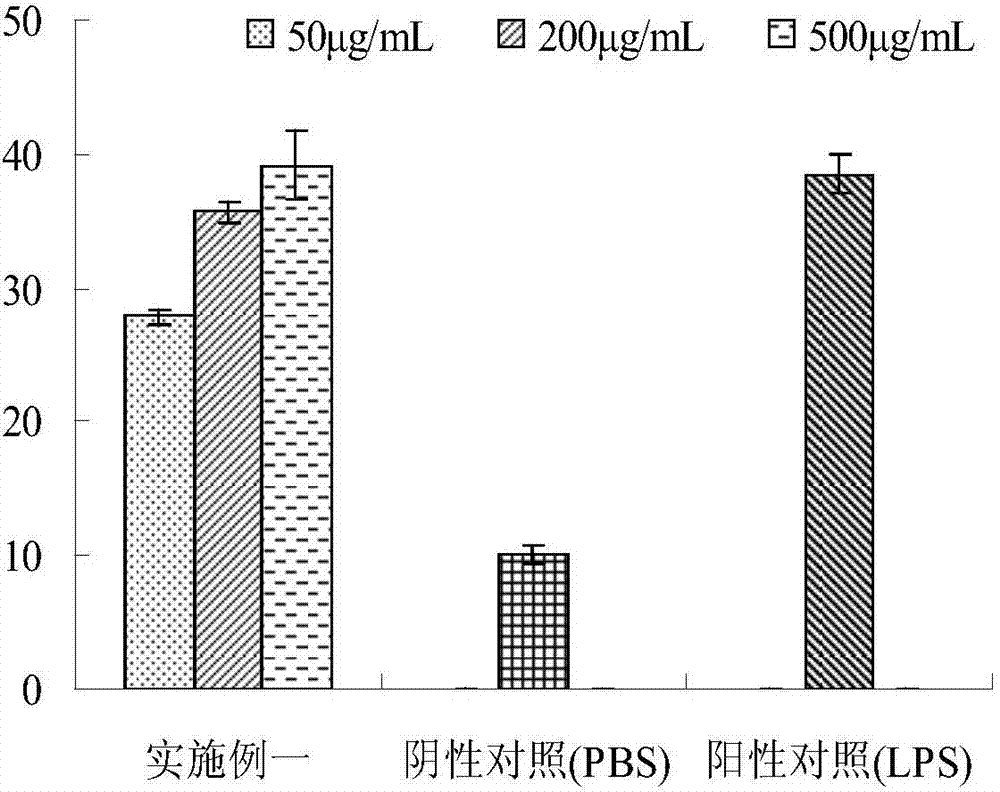

Embodiment 1

[0024] 1 Crude polysaccharide extraction: Weigh 500g of Pleurotus eryngii leftovers (Shanghai Bei'an Fungus Professional Cooperative), add 6.5L of water, bath in boiling water for 2h, filter, centrifuge the filtrate at 10000r / min for 15min, add water to the residue 6L, bath in boiling water for 1h , filtered, the filtrate was centrifuged at 10000r / min for 15min, and the supernatants extracted twice were combined.

[0025] 2 Ultrafiltration of supernatant: The ultrafiltration equipment is a nanofiltration ultrafiltration reverse osmosis integrated machine (BH-UF-NF-RO-3-2012, Shanghai Beihong Biotechnology Co., Ltd.), using a roll-type ultrafiltration membrane of 100kDa (model PSI1, Ande Membrane Separation Technology Engineering Co., Ltd.), the ultrafiltration pressure is 0.15-0.2MPa, the ultrafiltration temperature is room temperature, and the ultrafiltration time is 2h. The ultrafiltration was terminated when the final conductivity was less than 80 μs / cm, and the retentate a...

Embodiment 2

[0030] 1 Crude polysaccharide extraction: Weigh 500g of Pleurotus eryngii offal pieces (Shanghai Beian Fungus Industry Professional Cooperative), add 7L of water, bath in boiling water for 2h, filter, centrifuge the filtrate at 10000r / min for 15min, add 6L of water to the residue, bath in boiling water for 1h, After filtering, the filtrate was centrifuged at 10,000 r / min for 15 min, and the supernatants extracted twice were combined.

[0031] 2 Supernatant ultrafiltration: The ultrafiltration equipment is a nanofiltration ultrafiltration reverse osmosis integrated machine (BH-UF-NF-RO-3-2012, Shanghai Beihong Biotechnology Co., Ltd.), using a roll-type ultrafiltration membrane of 100kDa, ultrafiltration The filtration pressure is 0.15-0.2MPa, the ultrafiltration temperature is room temperature, and the ultrafiltration time is 2h. During this period, 3 times the volume of distilled water is added to dilute the supernatant, so that the final conductivity of the liquid passing thr...

Embodiment 3

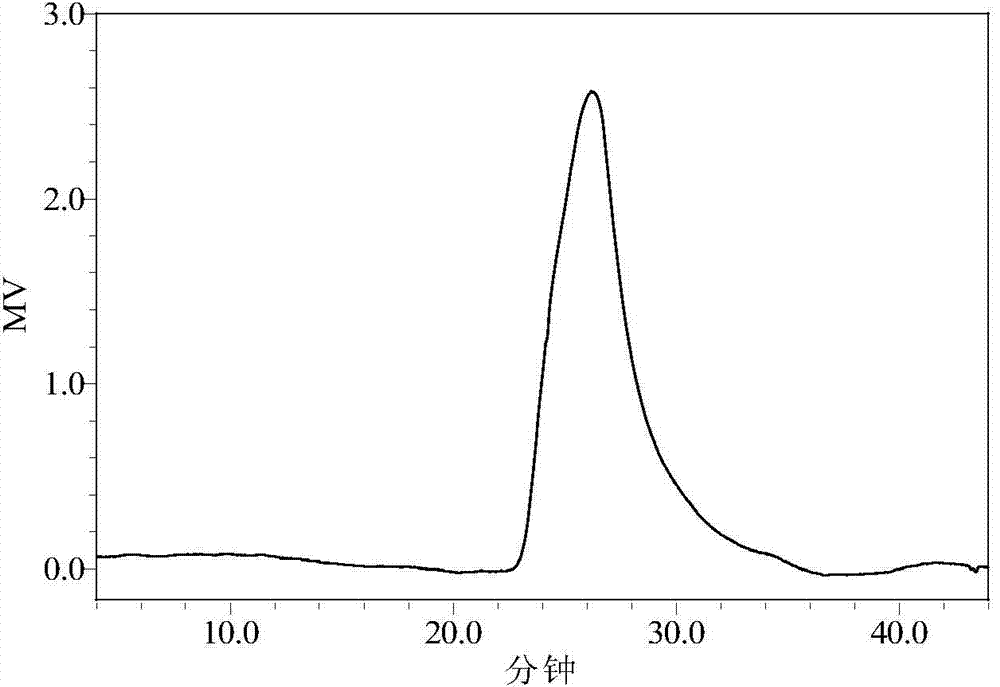

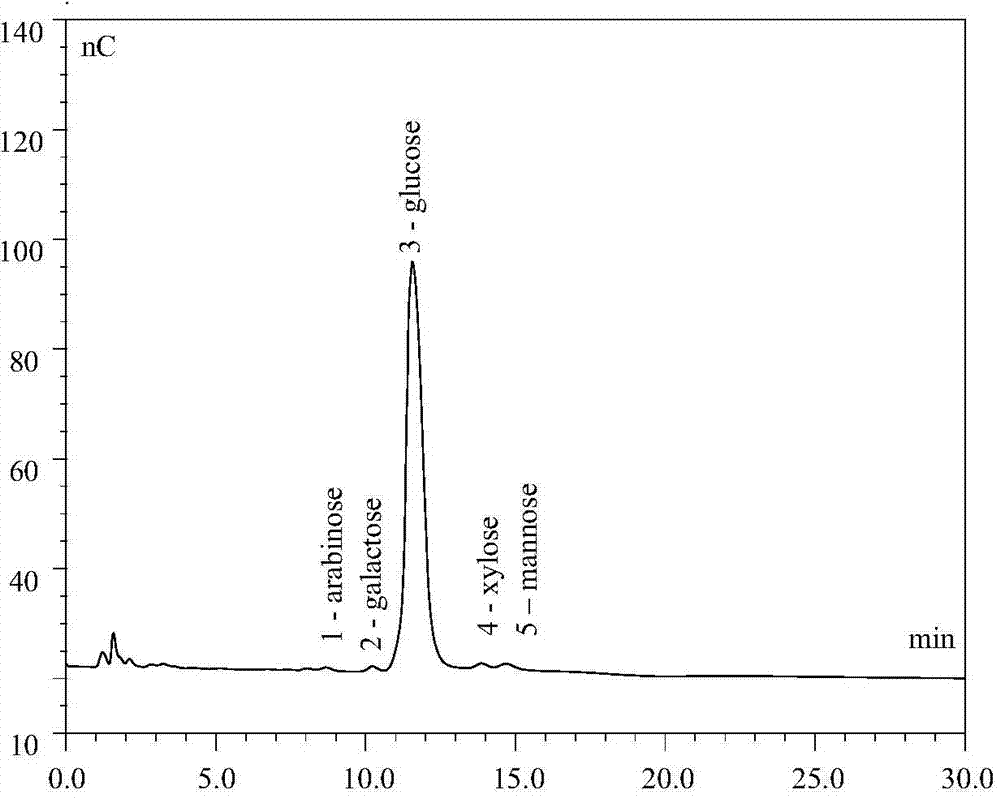

[0036] 1. Sample preparation: Weigh 2 mg of the high molecular weight Pleurotus eryngii polysaccharide prepared in Example 1, add 1 mL of mobile phase (containing 0.05 mol / L of NaH 2 PO 4 and 0.15mol / L NaNO 3 solution), fully dissolved, centrifuged at 13000r / min for 10min, and the supernatant was filtered through a 0.45μm aqueous microporous membrane (Shanghai Anpu Scientific Instrument Co., Ltd.) for HPSEC-MALLS-RI analysis.

[0037] 2. Chromatographic analysis conditions: HPSEC-MALLS-RI System combined with HPSEC-MALLS-RI System: Waters2695 HPLC, helium-neon The eight-angle laser light scattering detector (MALLS, Wyatt Company) of the laser light source and the Waters 2414 differential detector (RI) are composed. The analytical column is TSK PWXL 6000 and TSK PWXL 4000 gel chromatographic column (TOSOH company) connected in series for analysis, and the mobile phase is NaH containing 0.05mol / L 2 PO 4 and 0.15mol / L NaNO 3 solution (pH=7, 0.02% sodium azide), the flow rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com