Preparation method for molecularly imprinted composite membrane initiated by surface functional prepolymerization system

A technology of molecular imprinting and composite membranes, which is applied in the direction of chemical instruments and methods, ion exchange, alkali metal compounds, etc., to achieve fast adsorption kinetic properties, not easy to damage, and many times of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

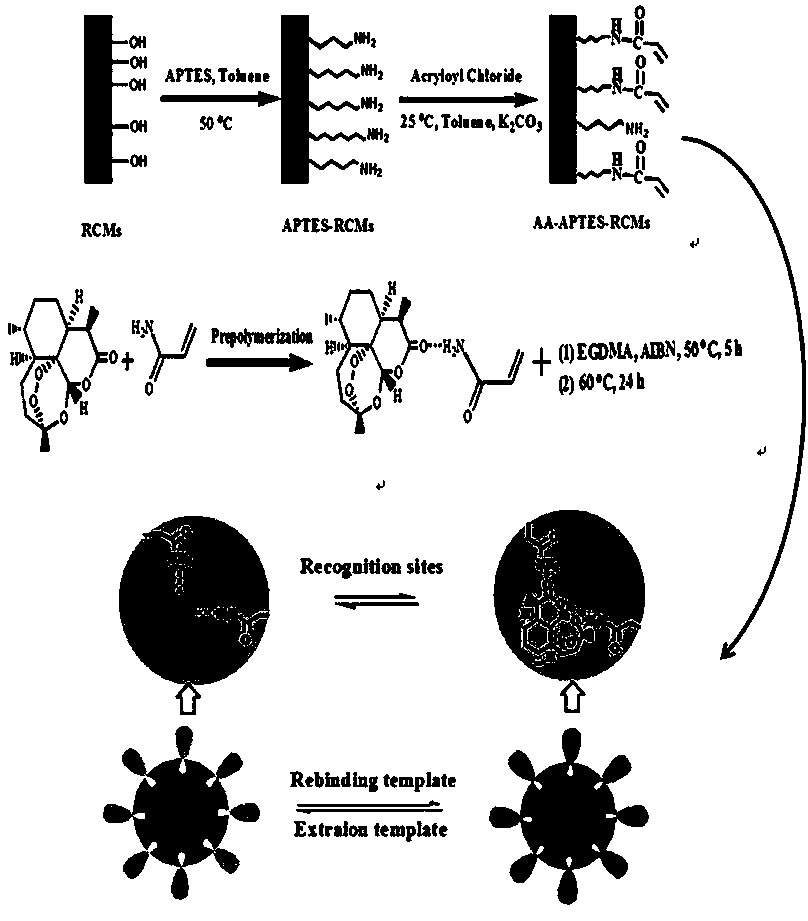

[0049] (1) Functional modification of regenerated cellulose membrane surface

[0050] First, 1.5 mL of 3-aminopropyltriethoxysilane (APTES) and 1 piece of regenerated cellulose membrane were placed in 50 mL of anhydrous toluene solution, mixed thoroughly under ultrasonic conditions, and 0.2 mL triethylamine is used as catalyst and is added in the above-mentioned solution, seals reaction flask mouth with parafilm, 50 o The reaction was heated at C for 12 h, and the obtained product (APTES-RCMs) was vacuum-dried to constant weight. Then, 0.5 mL of acryloyl chloride (AC) and the prepared 1 piece of APTES-RCMs were dissolved in 50 mL of anhydrous toluene, and after passing nitrogen for 30 min, 10 mg of anhydrous potassium carbonate was added to the above solution as a catalyst, Seal the mouth of the reaction flask with parafilm, react at room temperature for 10 hours, and finally vacuum-dry the obtained product (AM-APTES-RCMs) to constant weight.

[0051] (2) Synthesis of artemi...

Embodiment 2

[0064] (1) Functional modification of regenerated cellulose membrane surface

[0065] First, put 4.5 mL of 3-aminopropyltriethoxysilane (APTES) and 3 pieces of regenerated cellulose membranes in 50 mL of anhydrous toluene solution, mix thoroughly under ultrasonic conditions, and pass nitrogen for 30 minutes, then add 0.2 mL triethylamine is used as catalyst and is added in the above-mentioned solution, seals reaction flask mouth with parafilm, 50 o The reaction was heated at C for 12 h, and the obtained product (APTES-RCMs) was vacuum-dried to constant weight. Then, 1.5 mL of acryloyl chloride (AC) and the prepared 3 pieces of APTES-RCMs were dissolved in 50 mL of anhydrous toluene, and after passing nitrogen for 30 min, 10 mg of anhydrous potassium carbonate was added to the above solution as a catalyst, Seal the mouth of the reaction flask with parafilm, react at room temperature for 10 hours, and finally vacuum-dry the obtained product (AM-APTES-RCMs) to constant weight. ...

Embodiment 3

[0079] (1) Functional modification of regenerated cellulose membrane surface

[0080]First, put 6 mL of 3-aminopropyltriethoxysilane (APTES) and 4 pieces of regenerated cellulose membranes into 50 mL of anhydrous toluene solution, and mix thoroughly under ultrasonic conditions. After 30 minutes of nitrogen, 0.2 mL triethylamine is used as catalyst and is added in the above-mentioned solution, seals reaction flask mouth with parafilm, 50 o The reaction was heated at C for 12 h, and the obtained product (APTES-RCMs) was vacuum-dried to constant weight. Then, 2 mL of acryloyl chloride (AC) and the prepared 4 pieces of APTES-RCMs were dissolved in 50 mL of anhydrous toluene, and after passing through nitrogen for 30 minutes, 10 mg of anhydrous potassium carbonate was added to the above solution as a catalyst, and the The mouth of the reaction flask was sealed with parafilm, and the reaction was carried out at room temperature for 10 hours. Finally, the obtained product (AM-APTES-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com