Preparation method and device for wrapping metal wires with carbon nanomaterials

A technology of carbon nanomaterials and metal wires, applied in the direction of metal material coating process, coating, etc., can solve the problems of difficult to achieve large length and mass production, complex preparation process, etc., achieve safety and easy production, good electrical conductivity, The effect of good mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

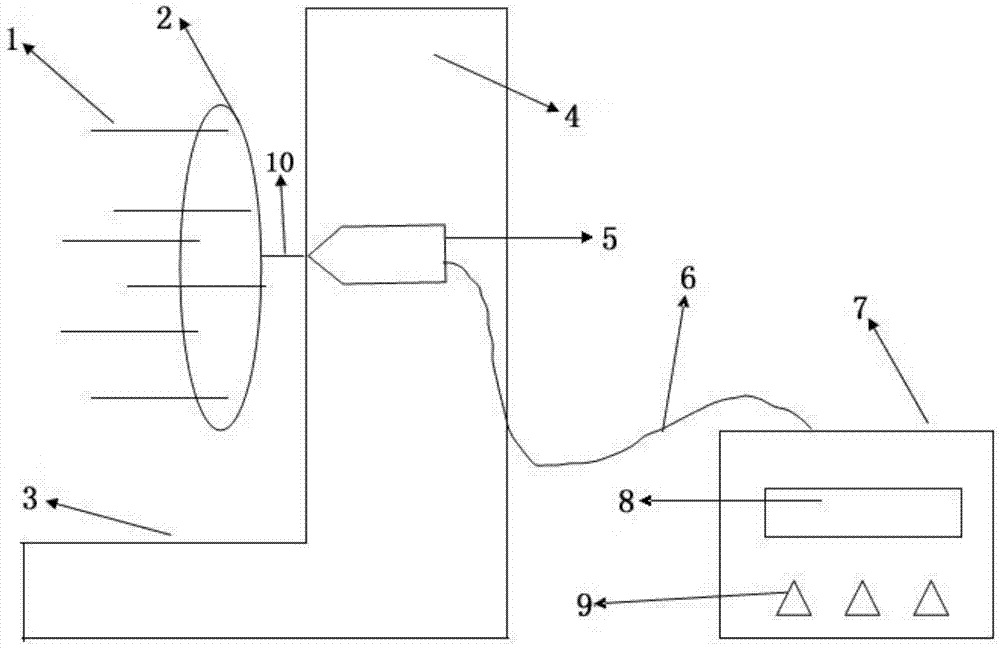

[0033] (1) Select N (N>2, and it is an integer) copper wires of equal length, clean them, arrange the selected wires neatly and bundle them together, and wind them at the corresponding positions of the experimental device.

[0034] (2) Add 0.02-0.5 grams of single-walled carbon nanotubes to the mixed suspension of water and isopropanol with a volume ratio of 0.1-10, and then add 0.001-0.1 grams of sodium lauryl sulfate and 0.0001-0.001 grams of fiber Suspensions of single-walled carbon nanotubes.

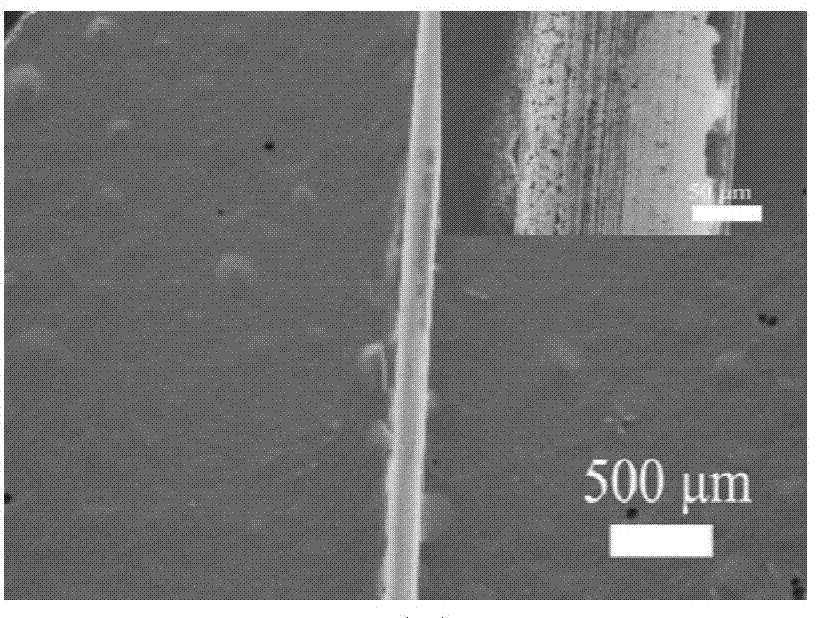

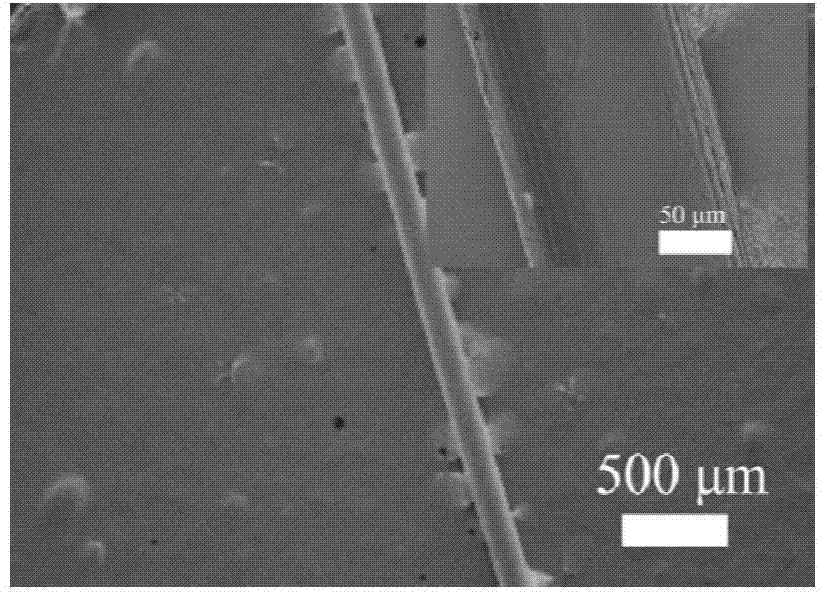

[0035] (3) Immerse the wound copper wire into the single-wall carbon nanotube suspension, adjust the rotating speed to make it rotate at a uniform speed in the single-wall carbon nanotube suspension, then take it out and dry it at 1-200 ° C. This process can The process is carried out several times, and then the neatly arranged and bundled metal wires are separated to prepare highly conductive single-walled carbon nanotube-wrapped copper wires.

Embodiment 2

[0037] (1) Select a section of bundled single-walled carbon nanotube-wrapped copper wire in Example 1, and wind it at the corresponding position of the experimental device.

[0038] (2) 0.02-0.5 gram of graphene is added to the mixed suspension of water and isopropanol with a volume ratio of 0.1-10, and then 0.001-0.1 gram of sodium lauryl sulfate and 0.0001-0.001 gram of cellulose are added to prepare into a graphene suspension.

[0039] (3) Place the copper wire wrapped by the wound single-walled carbon nanotubes in the graphene suspension, adjust the rotating speed to make it rotate at a constant speed in the graphene suspension, take it out and dry it at 1-200 ° C, this process It can be carried out multiple times, and then the neatly arranged and bundled metal wires are separated to prepare copper wires wrapped with single-walled carbon nanotubes and graphene in sequence.

Embodiment 3

[0041] (1) Select N (N>2, and it is an integer) sections of nickel metal wires of equal length to clean, arrange the metal wires neatly and bundle them together, and wind them at the corresponding positions of the experimental device.

[0042] (2) Add 0.02-0.5 g of single-walled carbon nanotubes to the tetrahydrofuran suspension, and then add 0.001-0.1 g of polyvinyl alcohol and 0.0001-0.001 g of epoxy resin to prepare the single-walled carbon nanotubes suspension.

[0043] (3) Immerse the wound nickel wire into the single-wall carbon nanotube suspension, adjust the rotating speed to make it rotate at a constant speed in the single-wall carbon nanotube suspension, and then take it out and dry it at 1-200 ° C. This process It can be carried out many times, and then the neatly arranged and bundled nickel metal wires are separated to prepare highly conductive nickel metal wires wrapped by single-walled carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com