A cryogenic liquid storage and transportation tank insulated by a vacuum insulation board

A technology of vacuum insulation panels and cryogenic liquids, which is applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, pressure vessels, etc. It can solve problems such as poor stability, small storage capacity, and poor thermal insulation effect, and achieve thermal insulation Improved heat insulation effect, light weight, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

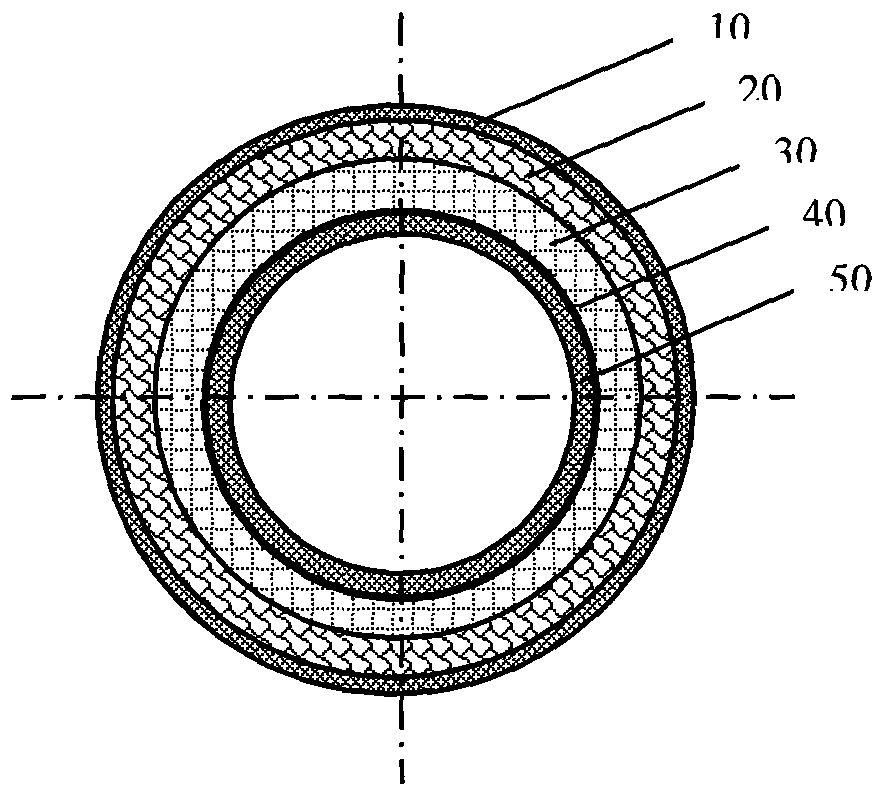

[0019] A cylindrical vacuum insulation board-insulated cryogenic liquid storage and transportation tank, which is composed of a C1.2 steel inner tank, a vacuum insulation board wrapped around the inner tank, a thin polyurethane foam layer and a stainless steel outer tank, wherein the inner , The thickness of the outer tank is 5mm, and the thickness of the vacuum insulation board wrapped around the inner tank is 40mm. Among them, polyetheramine modified epoxy resin is glued between the inner tank and the vacuum insulation board, and the thickness of the polyurethane foam filled between the vacuum insulation board and the outer tank is 30 mm. The tank body has excellent thermal insulation performance, has the advantages of safety, light weight, environmental protection, intelligence, large capacity, and long life. It can store cryogenic liquids, improve the use efficiency of liquefied natural gas, etc., and reduce the inflation frequency of ships.

Embodiment 2

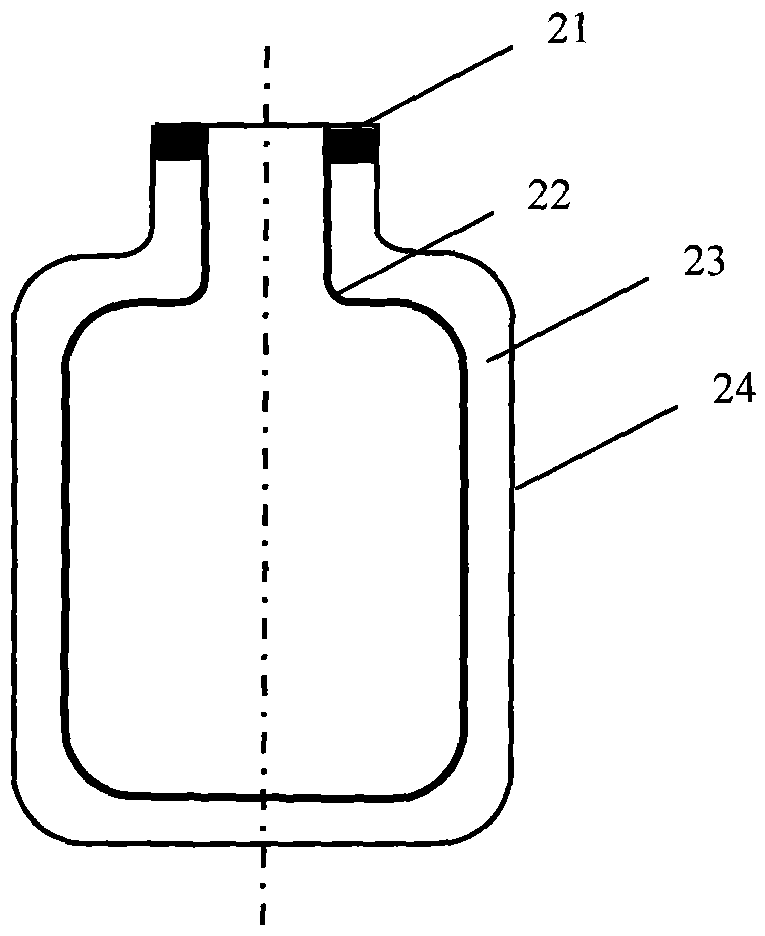

[0021] A cryogenic liquid storage and transportation tank insulated by a spherical vacuum insulation panel, which is composed of a stainless steel inner tank, a vacuum insulation material layer wound on the surface of the inner tank, a thin layer of polyurethane foam and a carbon fiber reinforced resin matrix composite material shell, wherein, in the thickness The opening neck of the inner tank is sprayed with 2mm, and the outer surface of the inner tank is tightly covered with a bag-shaped packaging film material with thermoplastic polyimide. The composite film material encapsulates the wound inner tank as a whole and vacuumizes it, and obtains a vacuum insulation material layer with a thickness of 35mm outside the inner tank. On the outside of the vacuum insulation layer is a polyurethane foam layer with a thickness of 20mm and a carbon fiber reinforced epoxy resin matrix composite shell with a thickness of 5mm. The tank body has excellent thermal insulation performance, has...

Embodiment 3

[0023] A cryogenic liquid storage and transportation tank with frustum-shaped vacuum insulation panels, which is composed of a C1.2 steel inner tank, a vacuum insulation material layer wound on the surface of the inner tank, a thin polyurethane foam layer and a glass fiber reinforced resin-based composite material shell , wherein the thickness of the inner tank is 4mm, and a Teflon annular plastic layer with a thickness of 20mm is sprayed on the opening neck of the inner tank, and thermoplastic polyimide is tightly laminated and wound with 40 layers of glass wool core material and aluminum foil below the neck, Vacuumize the bag-shaped composite film material and heat seal with the annular Teflon layer to obtain a vacuum insulation material layer with a thickness of 30mm outside the inner tank. Outside the vacuum insulation layer is a polyurethane foam layer with a thickness of 15mm and a glass fiber reinforced epoxy resin based composite shell with a thickness of 7mm. The tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com