Method for manufacturing CZTS thin film solar cell absorbing layer

A thin-film solar cell and absorption layer technology, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult to form CZTS thin-film solar cells industrialized production, low-quality specific power of thin-film solar cells, and narrowing the use range of batteries, etc. Achieve the effect of improving electrical performance, improving conversion efficiency and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the CZTS thin film solar cell absorbing layer is characterized in that it comprises the following preparation steps:

[0021] Step 1: Fix the flexible substrate with the film-coated side facing down under the sample holder below the rotating shaft on the top wall of the vacuum evaporation chamber, and a movable substrate baffle is placed under the flexible substrate; the top of the sample holder Fix a thermocouple, and there is a substrate heater on the rotating shaft above the thermocouple; the Cu evaporation source, Zn evaporation source, NaF evaporation source, Sn evaporation source and Se evaporation source are placed in the vacuum evaporation chamber at any angle and height. Among the adjusted five wedge-shaped evaporation source bases, the distance from the top of the Cu evaporation source, Zn evaporation source, NaF evaporation, and Sn evaporation source to the center of the bottom of the substrate is ≤ 30cm, and the distance from the top...

Embodiment

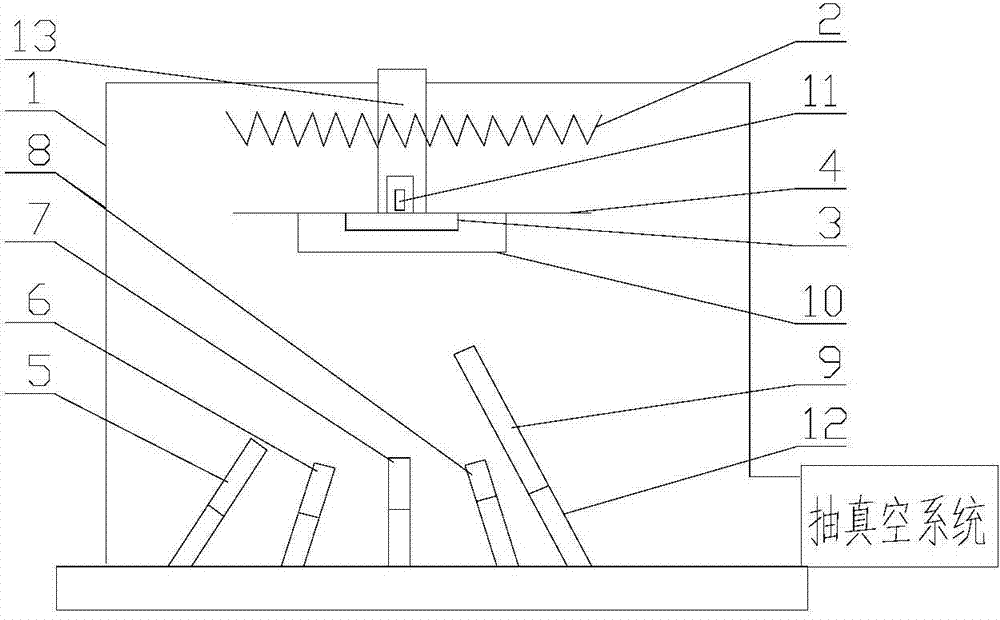

[0027] Step 1: If figure 1 As shown, a vacuum evaporation chamber 1 is set on the top wall to rotate the rotating shaft 13 through the outside; the 10×10cm 2 The PI flexible substrate 3 is coated with a 500-800nm Mo back electrode on one side, and the Mo back electrode on the flexible substrate is fixed on the bottom of the rotating shaft. Below, below the flexible substrate, there is a substrate baffle plate 10 installed under the sample holder and can be opened and closed in the vacuum evaporation chamber; a thermocouple 11 is fixed above the sample holder, and the rotation axis above the thermocouple is fixed horizontally to The serpentine coiled furnace wire is used as the substrate heater 2; there are five evaporation source bases 12 arranged in a ring at the bottom of the vacuum evaporation chamber, and the angle and height can be adjusted, each with a Cu evaporation source 5 and a Zn evaporation source with a heater Source 6, NaF evaporation source 7, Sn evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com