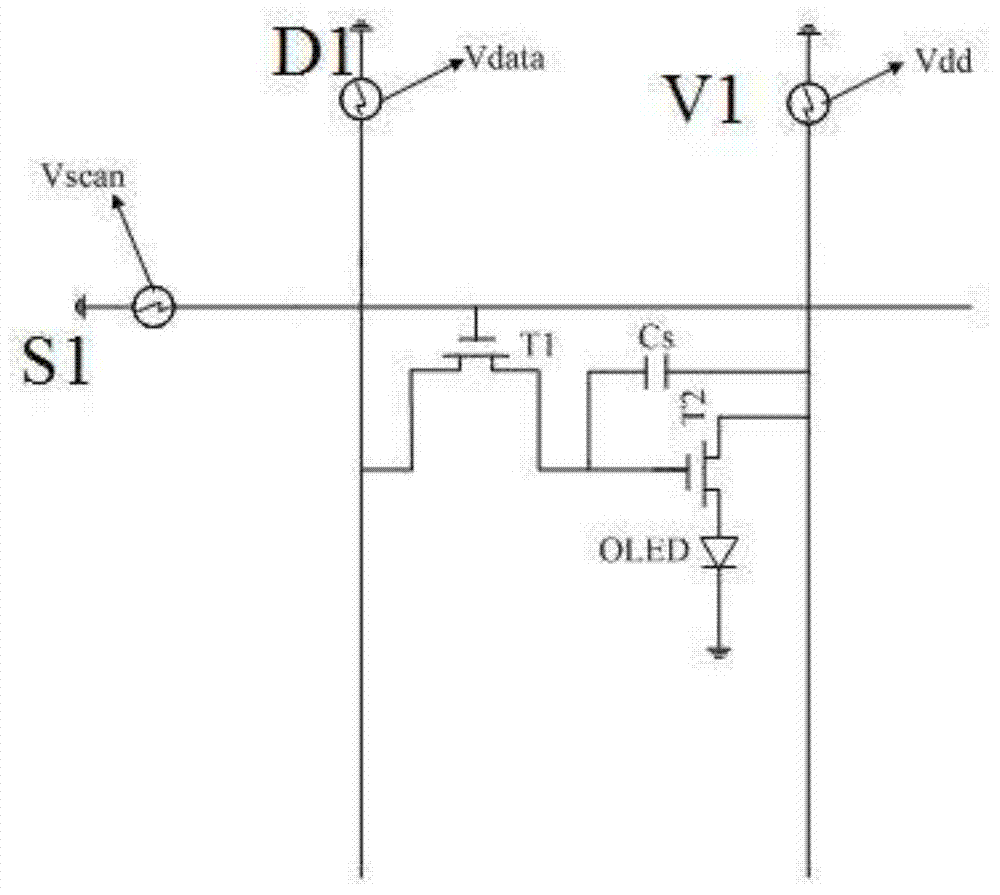

Semiconductor device and manufacturing method thereof

A semiconductor and device technology, applied in the display field, can solve the problems of reduced voltage withstand performance of capacitors, and achieve the effect of solving the problem of reduced voltage withstand performance, excellent voltage withstand performance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

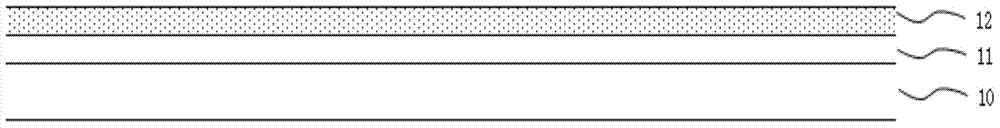

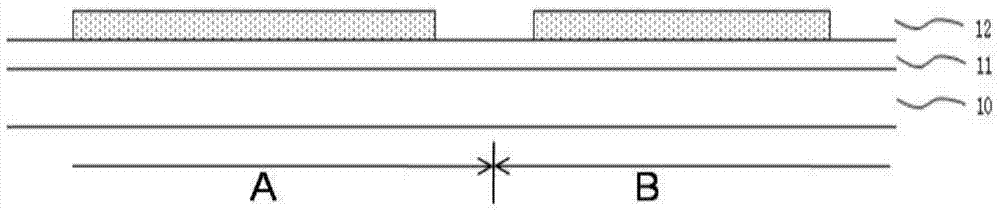

[0040] This embodiment provides a method for preparing a semiconductor device and a semiconductor device prepared therefor, including the following steps:

[0041] S1, such as figure 2 As shown, a semiconductor layer 12 is formed on a substrate 10 including a thin film transistor region A and a capacitor region B; image 3 As shown, the semiconductor layer 12 is patterned by photolithography and dry etching processes to form island-shaped patterns in the thin film transistor region A and capacitor region B respectively.

[0042] The substrate 10 is selected from but not limited to a glass substrate, a polymer substrate or a metal substrate, all of which can achieve the purpose of the present invention and belong to the protection scope of the present invention. In this embodiment, a glass substrate is preferred; the substrate 10 is divided into a thin film transistor region A and a capacitor region B, but there is no clear boundary between them. The thin film transistor is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com