Acidified mixed crystal TiO2 nanowire loaded photocatalyst and preparation and application of photocatalyst

A photocatalyst and nanowire technology, which is applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of high photogenerated electron-hole pair recombination rate, solar Low light utilization rate, low responsiveness and other problems, to achieve the effect of broadening the scope of application, easy separation and recovery, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

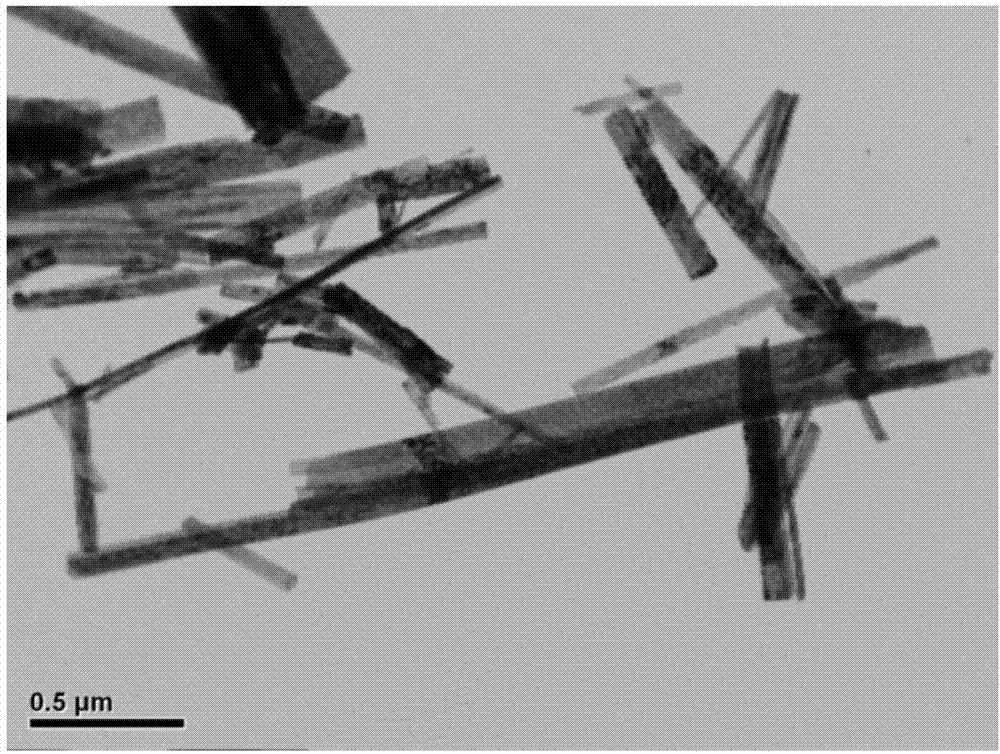

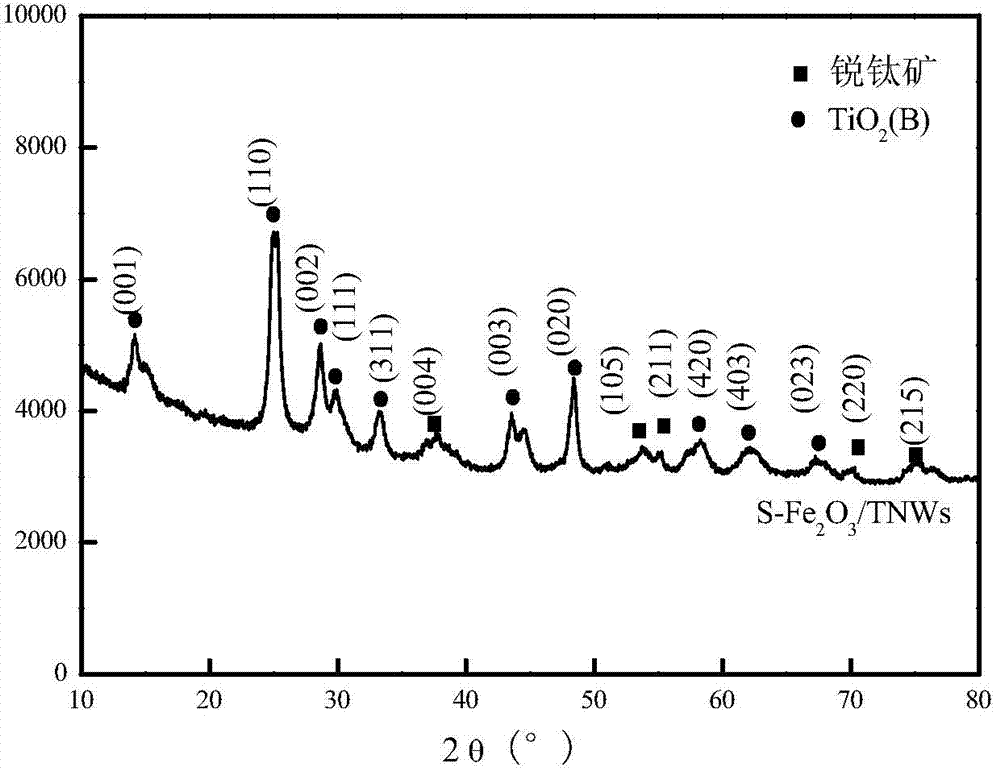

[0024] Example 1: Acid-functionalized mixed crystal TiO 2 nanowire loaded Fe 2 o 3 Catalyst Synthesis

[0025] (1) Disperse titanium dioxide P25 (Germany Degussa company, purity 99.5%, CAS No. NO: 13463-67-7) powder (1.5g) in 10M NaOH aqueous solution (140mL), and ultrasonically mix to obtain a suspension , put the suspension in a hydrothermal kettle, react at 200°C for 24h, cool to room temperature, filter out the precipitate, place it in 0.1M hydrochloric acid aqueous solution (150mL) for acidification, rinse with deionized water, and place in Dry in a vacuum drying oven to obtain titanate nanowires, then place the obtained titanate nanowires in a muffle furnace and calcinate at 600°C for 4 hours to obtain white mesoporous mixed crystal TiO 2 Nanowires (TNWs) 1.0 g;

[0026] (2) The obtained mixed crystal TNWs (1.0 g) was placed in Fe(NO 3 ) 3(0.361g) and absolute ethanol / water (volume ratio 1:1, 50ml) solution, add dropwise 0.5M sulfuric acid aqueous solution (1ml), i...

Embodiment 2

[0029] Example 2: Acid-functionalized mixed crystal TiO 2 Nanowire loaded Co 2 o 3 Catalyst Synthesis

[0030] (1) with embodiment 1 step (1);

[0031] (2) Place the obtained mixed crystal TNWs (1.0 g) in Co(NO 3 ) 2 (0.197g) and absolute ethanol / water (volume ratio 1:1, 80ml), add dropwise 0.5M sulfuric acid aqueous solution (1mL), immerse and stir to obtain a suspension, which is transferred to a hydrothermal kettle , reacted at 60°C for 6h, cooled to room temperature, discarded the supernatant, and dried in vacuum to obtain solid S-Co 2 o 3 / mixed crystal TNWs 0.8g.

Embodiment 3

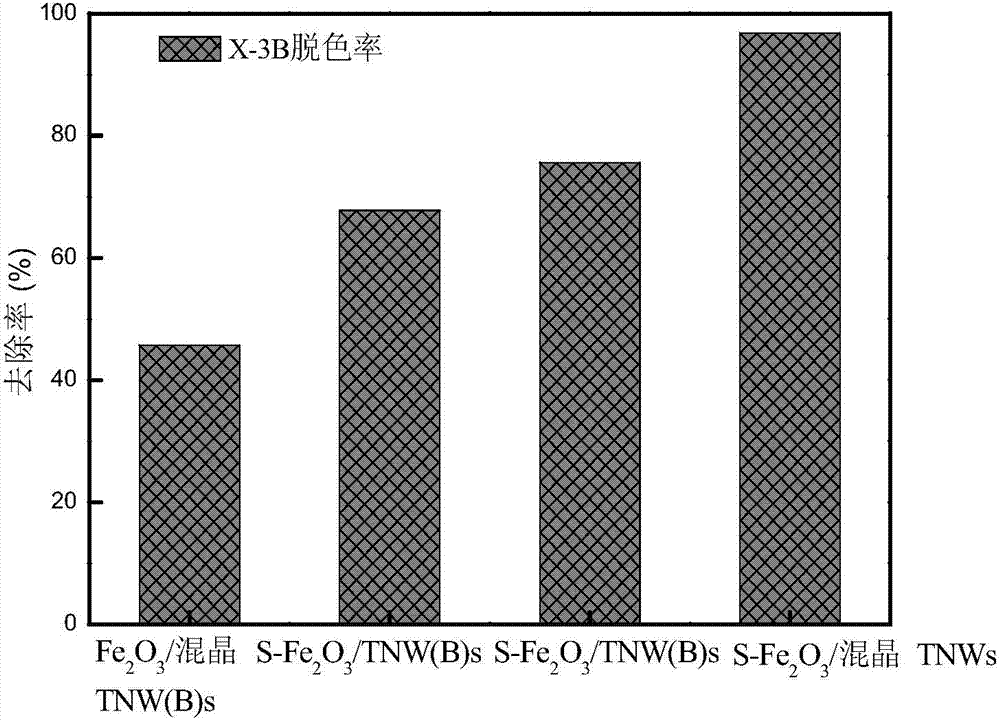

[0040] The catalysts prepared in Examples 1-2 and Comparative Examples 1-2 were applied to the photocatalytic degradation reaction of organic printing and dyeing wastewater. The effect of functional modification and carrier selection on catalytic performance was analyzed by calculating and analyzing the decolorization rate of printing and dyeing wastewater.

[0041] Experimental steps for photocatalytic degradation of active organic printing and dyeing wastewater: prepare 1L of reactive brilliant red X-3B dye solution with a concentration of 100mg / L, adjust the pH of the reaction solution to 6.0 with dilute hydrochloric acid or sodium hydroxide solution according to the experimental requirements, and then weigh them respectively Take 0.5 g of each of the above catalysts and add them into the dye solution, turn on the magnetic stirrer, and mix the catalyst and the dye solution evenly. Before the photocatalytic degradation experiment, the reaction solution was shaken for 30 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com