Graphite type carbon nitride-metal organic frame composite photocatalyst as well as preparation method and application of graphite type carbon nitride-metal organic frame composite photocatalyst

A graphite-type carbon nitride and metal organic framework technology, applied in the field of photocatalysis, can solve the problems of easy recombination and small specific surface area of the catalyst, and achieve the effects of low preparation cost, high visible light catalytic activity, and improved quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

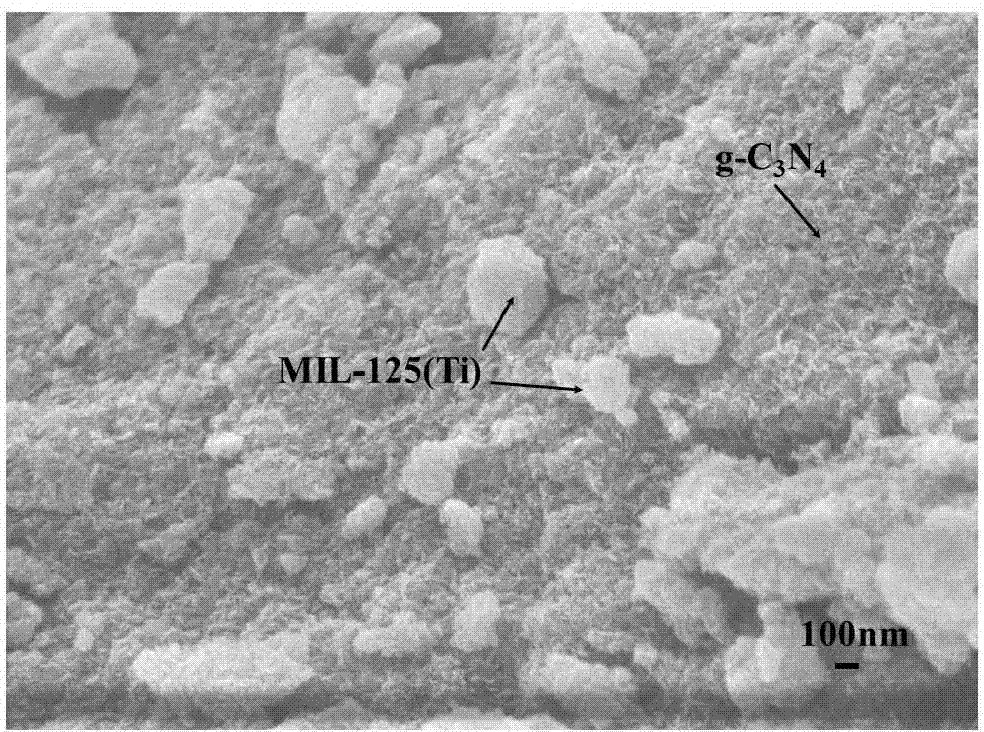

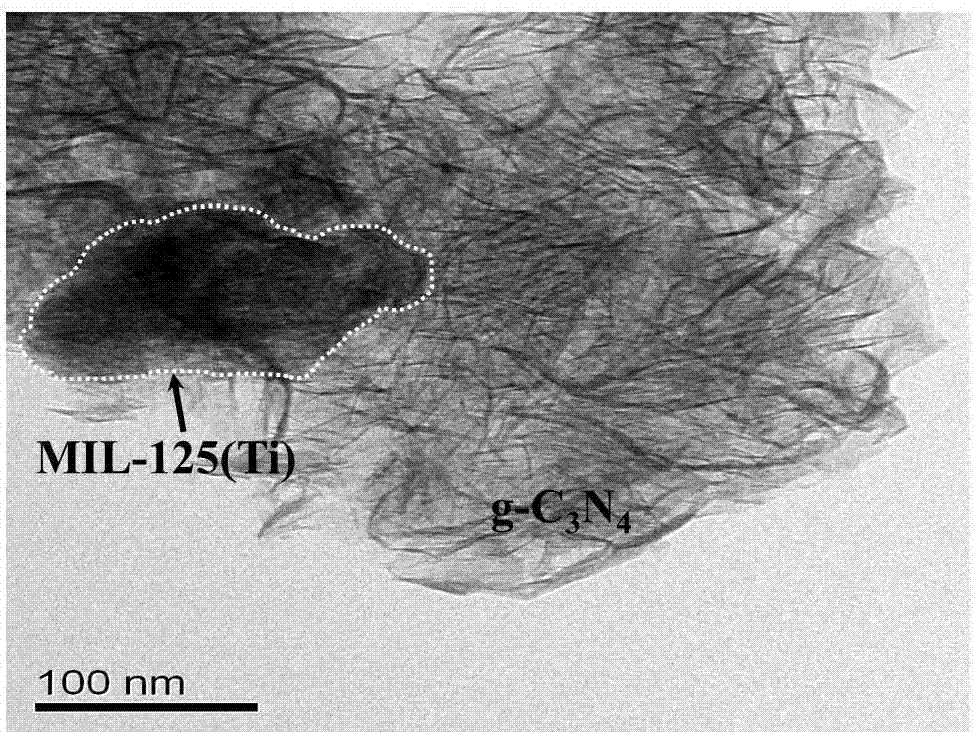

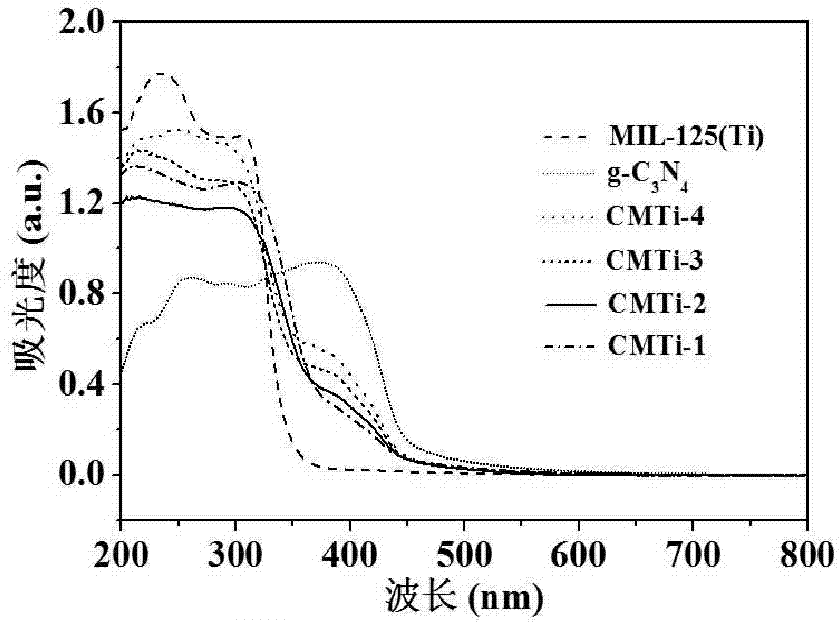

[0034] A graphite carbon nitride-metal organic framework composite photocatalyst of the present invention uses graphite carbon nitride as a carrier, MIL-125 (Ti) particles grow freely on the surface of graphite carbon nitride, MIL-125 (Ti) Carbon nitride nanosheets are loaded on the particle surface.

[0035] Its preparation method specifically comprises the following steps:

[0036] (1) Take 50 mg of block graphite carbon nitride and add it to 36 mL of dimethylformamide, and ultrasonically disperse for 2 hours to obtain a graphite carbon nitride dispersion.

[0037] (2) Add 2.4 mL of n-butyl titanate, 4 mL of methanol and 2.2 g of terephthalic acid to the carbon nitride dispersion prepared in step (1) and stir to obtain a mixed solution.

[0038] (3) Transfer the mixed solution prepared in step (2) to a polytetrafluoroethylene-lined reactor, seal it, and react at 150°C for 48 hours. Naturally cooled to room temperature to obtain a pale yellow precipitate.

[0039] (4) The ...

Embodiment 2

[0043] A graphite-type carbon nitride-metal organic framework composite photocatalyst of the present invention uses graphite-type carbon nitride as a carrier, MIL-125 (Ti) particles grow freely on the surface of the graphite-type carbon nitride, MIL-125 ( Ti) particles are loaded with carbon nitride nanosheets on the surface.

[0044] Its preparation method specifically comprises the following steps:

[0045] (1) Add 11.5 mg of block graphite carbon nitride into 36 mL of dimethylformamide, and disperse ultrasonically for 2 hours to obtain a graphite carbon nitride dispersion.

[0046] (2) Add 2.4 mL of n-butyl titanate, 4 mL of methanol and 2.2 g of terephthalic acid to the carbon nitride dispersion prepared in step (1) and stir to obtain a mixed solution.

[0047] (3) Transfer the mixed solution prepared in step (2) to a polytetrafluoroethylene-lined reactor, seal it, and react at 150°C for 48 hours. Naturally cooled to room temperature to obtain a pale yellow precipitate.

...

Embodiment 3

[0050] A graphite-type carbon nitride-metal organic framework composite photocatalyst of the present invention uses graphite-type carbon nitride as a carrier, MIL-125 (Ti) particles grow freely on the surface of the graphite-type carbon nitride, MIL-125 ( Ti) particles are loaded with carbon nitride nanosheets on the surface.

[0051] Its preparation method specifically comprises the following steps:

[0052] (1) Take 200 mg of block graphite carbon nitride and add it to 36 mL of dimethylformamide, and ultrasonically disperse for 2 hours to obtain a graphite carbon nitride dispersion.

[0053] (2) Add 2.4 mL of n-butyl titanate, 4 mL of methanol and 2.2 g of terephthalic acid to the carbon nitride dispersion prepared in step (1) and stir to obtain a mixed solution.

[0054] (3) Transfer the mixed solution prepared in step (2) to a polytetrafluoroethylene-lined reactor, seal it, and react at 150°C for 48 hours. Naturally cooled to room temperature to obtain a pale yellow prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com