Non-sticking wear-resistant high-temperature-resistant paint and preparation method thereof

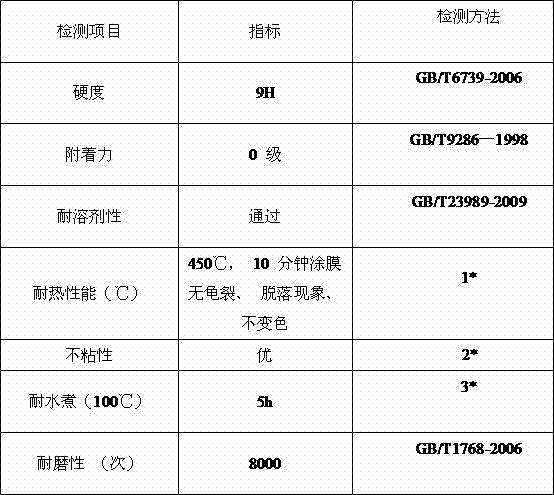

A high-temperature-resistant coating, sticky and wear-resistant technology, applied in the field of coatings, can solve the problems of affecting economic benefits, complex production process and low efficiency of non-stick ceramic coatings, and achieve non-toxic and harmless environment, good economic benefits, and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A non-stick, wear-resistant and high-temperature resistant coating, the weight of each component is:

[0018] 32 parts of silica sol, 28 parts of alumina sol, 16 parts of nano zirconium dioxide, 4 parts of polyacrylate, 8 parts of pigments, 3 parts of fluorosilane, 15 parts of water.

[0019] The preparation method includes the following steps:

[0020] The above-mentioned silica sol, alumina sol, nano-zirconia, pigment, and water are mixed in the stated proportions, and the mixture is sealed and mixed for 5 hours at a temperature of 36°C and 230 rpm until there are no sediments; then added according to the above proportions Polyacrylate and fluorosilane are sealed and mixed and stirred at 25° C. and 150 rpm for 0.5 h to obtain the non-stick, wear-resistant and high-temperature resistant coating of the present invention.

Embodiment 2

[0022] A non-stick, wear-resistant and high-temperature resistant coating, the weight of each component is:

[0023] 30 parts of silica sol, 25 parts of alumina sol, 10 parts each of nano zirconium dioxide and nano silicon carbide, 2 parts each of polyacrylate and polydimethylsiloxane, 10 parts of pigment, 3 parts of fluorosilane, 10 parts of water Copies.

[0024] The preparation method includes the following steps:

[0025] The above-mentioned silica sol, alumina sol, nano-zirconia, nano-silicon carbide, pigment, and water are mixed first in the stated proportions, and the mixture is sealed and mixed at 35°C and 200 rpm for 3 hours until there is no sediment; then Polyacrylate, polydimethylsiloxane, and fluorosilane are added in the above proportions, and the non-stick, wear-resistant and high-temperature resistant coatings of the present invention can be obtained by airtight mixing and stirring at 20° C. and 120 rpm for 0.3 hours.

Embodiment 3

[0027] A non-stick, wear-resistant and high-temperature resistant coating, the weight of each component is:

[0028] 25 parts of silica sol, 20 parts of alumina sol, 20 parts of nano silicon carbide, 5 parts of polydimethylsiloxane, 7 parts of pigment, 5 parts of fluorosilane, 12 parts of water.

[0029] The preparation method includes the following steps:

[0030] Mix the above silica sol, alumina sol, nano silicon carbide, pigment, and water according to the stated proportions, and mix and stir for 4 hours at 30°C and 250 rpm to ensure that there is no sediment; then add the polymer according to the above proportions. Dimethylsiloxane and fluorosilane are mixed and stirred in an airtight manner at 27° C. and 140 rpm for 0.4 hours to obtain the non-stick, wear-resistant and high-temperature resistant coating of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com