Hydrogen peroxide and glucose sensor based on hydrophilic up-conversion nano NaYF4

A hydrophilic, sensor technology, applied in nanotechnology for sensing, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as poor water solubility, short fluorescence lifetime, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Add 4.0 mg of sodium hydroxide to 10 mL of deionized water, and ultrasonically promote its complete dissolution;

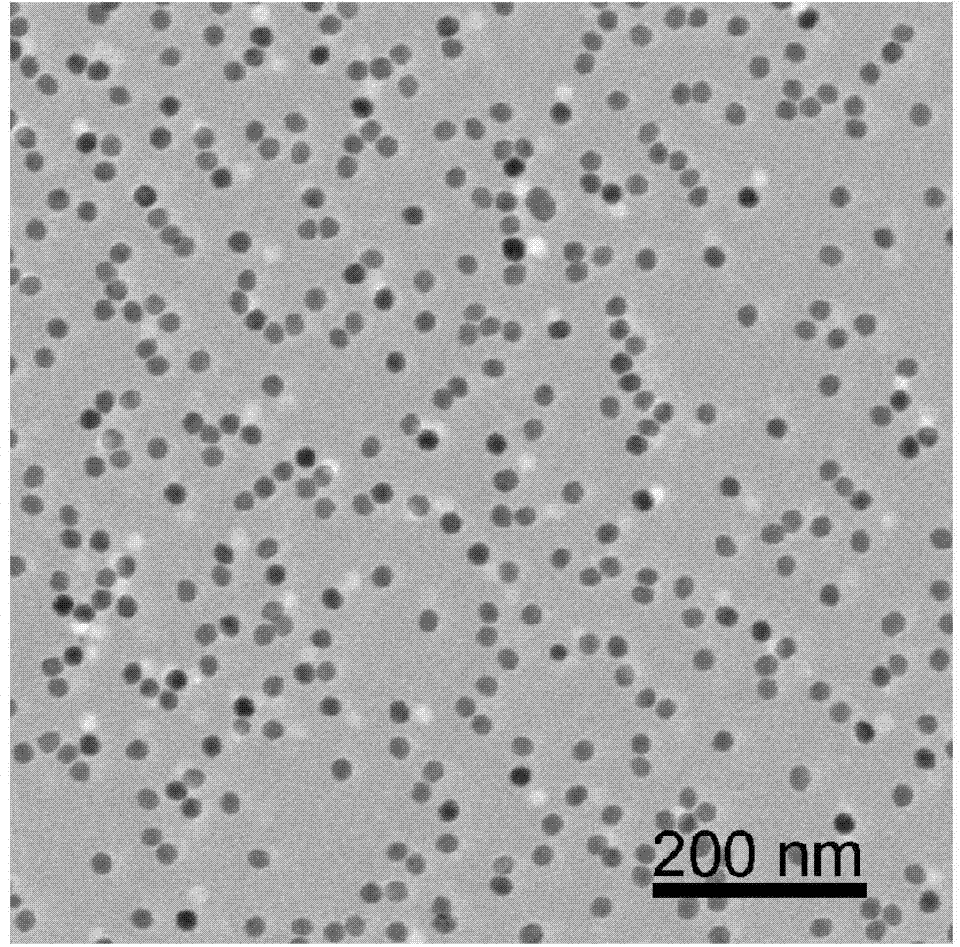

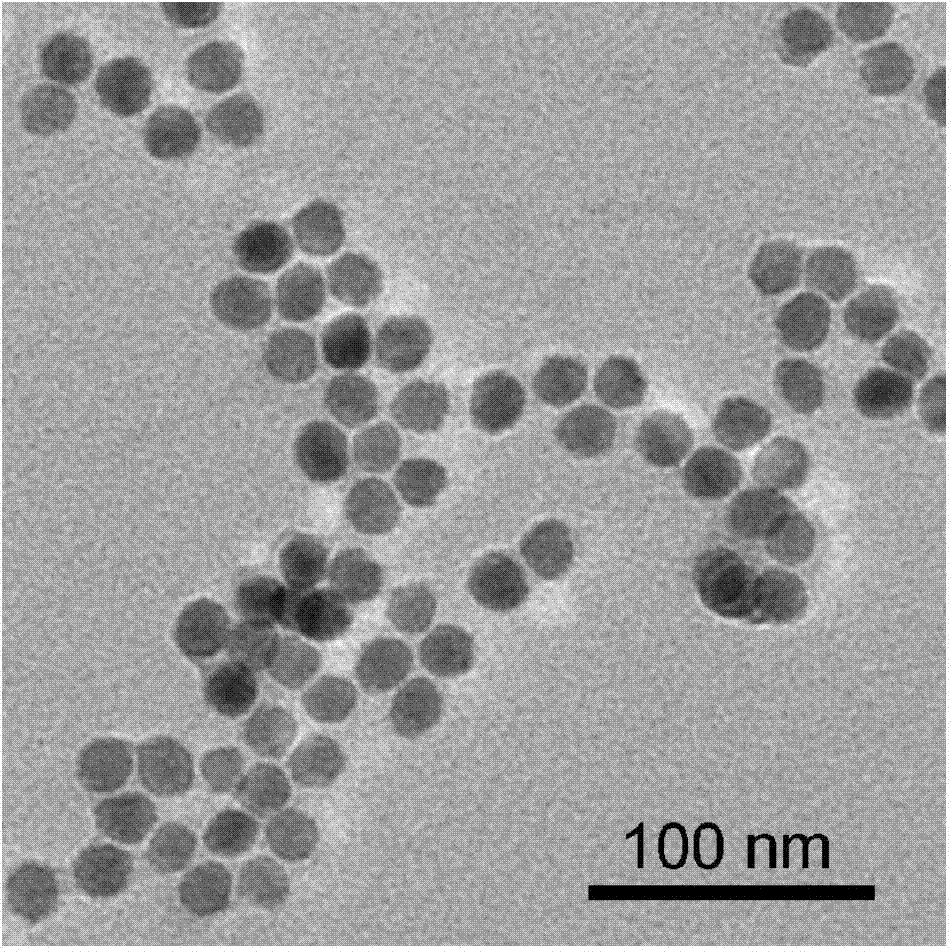

[0036] b. Add 200 μL of oleylamine-modified polysuccinimide polymer solution with a concentration of 0.365 mg / mL and 200 μL of rare earth up-conversion nanoparticle dispersion with a concentration of 0.25 mmol / mL in a 1.5 mL centrifuge tube, and mix the mixture with chloroform. The solution was fixed to 1 mL; the oleylamine-modified polysuccinimide polymer solution and the rare earth up-conversion nanoparticle dispersion both used chloroform as a solvent;

[0037] c. Add the mixed solution obtained in step b to the solution prepared in step a, and use an ultrasonic crushing instrument to sonicate for 6 minutes under an ice-water bath to finally obtain an oil-in-water microemulsion with an ultrasonic power of 200W; then under the condition of 300rpm magnetic stirring , the chloroform in the solution was volatilized at normal pressure in a water bath at 52...

Embodiment 2

[0052] a. Add 5.0 mg of sodium hydroxide to 12 mL of deionized water, and ultrasonically promote its complete dissolution;

[0053] b. Add 240 μL of oleylamine-modified polysuccinimide polymer solution with a concentration of 0.40 mg / mL and 240 μL of rare earth up-conversion nanoparticle dispersion with a concentration of 0.25 mmol / mL in a 1.5 mL centrifuge tube, and mix the mixture with chloroform. The solution was fixed to 1.2 mL; the oleylamine-modified polysuccinimide polymer solution and the rare earth up-conversion nanoparticle dispersion both used chloroform as a solvent;

[0054] c. Add the mixed solution obtained in step b to the solution prepared in step a, and use an ultrasonic crushing instrument to sonicate for 6 minutes under an ice-water bath to finally obtain an oil-in-water microemulsion with an ultrasonic power of 260W; then under the condition of 300rpm magnetic stirring , the chloroform in the solution was volatilized at normal pressure in a water bath at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com