A preparation method of petroleum pitch-based carbon quantum dots and application of the petroleum pitch-based carbon quantum dots prepared by the method

A technology of petroleum pitch and carbon-based quantum dots is applied in the application of petroleum pitch-based carbon quantum dots and the preparation of petroleum pitch-based carbon quantum dots. The effect of low production cost, low price and high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 2g of AH-70 at room temperature and put it into a 100ml flask, add 20ml of concentrated nitric acid and 60ml of concentrated sulfuric acid in sequence, then put the flask into a 700w ultrasonic cleaner for 10h to obtain a dispersion of petroleum asphalt; The petroleum asphalt dispersion was heated and refluxed in an oil bath at 100°C for 12 hours, cooled to room temperature, and adjusted to neutrality with NaOH and distilled water to obtain a crude product of carbon quantum dots; After filtering, the filtered solution was dialyzed for 72 hours at room temperature in a dialysis bag with a residual molecular weight of 3500 Da to obtain an aqueous solution of petroleum pitch carbon quantum dots. The prepared petroleum pitch-based carbon quantum dot aqueous solution can be further subjected to rotary evaporation to remove most of the water, and then centrifugally dried to obtain solid petroleum pitch-based carbon quantum dots.

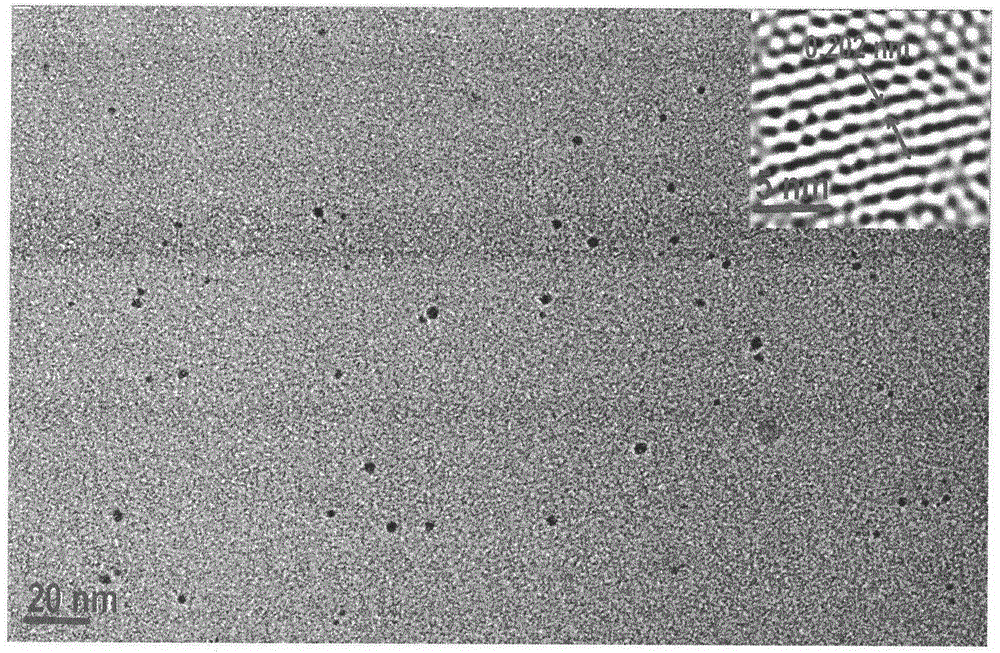

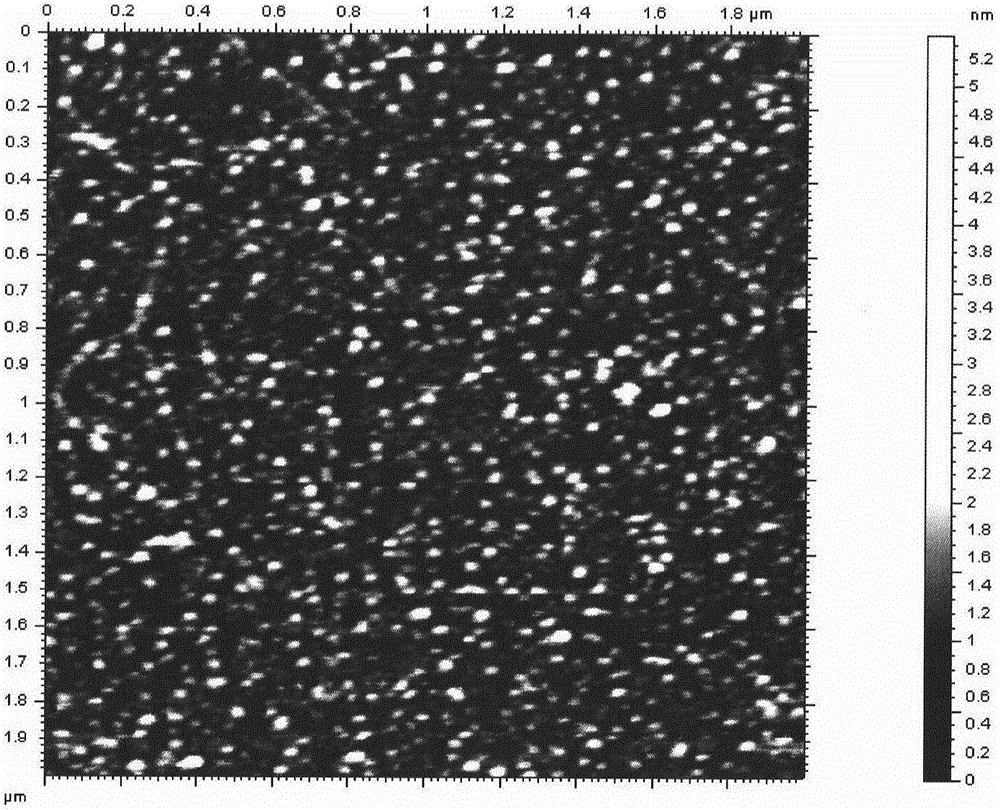

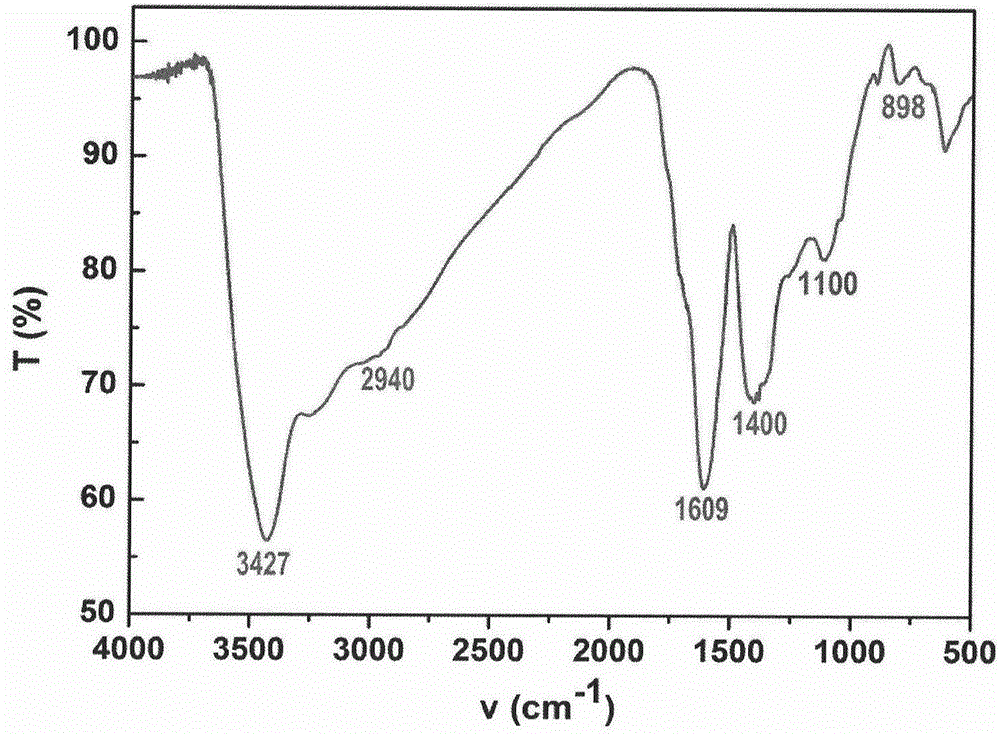

[0036] The petroleum pitch carbon quant...

Embodiment 2

[0038] Weigh 2g of AH-70 at room temperature and put it into a 100ml flask, add 20ml of concentrated nitric acid and 60ml of concentrated sulfuric acid in sequence, then put the flask into a 700w ultrasonic cleaner for 10h to obtain a dispersion of petroleum asphalt; The petroleum asphalt dispersion was heated and refluxed in an oil bath at 100°C for 24 hours, cooled to room temperature, and adjusted to neutrality with NaOH and distilled water to obtain a crude product of carbon quantum dots; After filtering, the filtered solution was dialyzed for 72 hours at room temperature in a dialysis bag with a molecular weight cut-off of 1000 Da to obtain an aqueous solution of petroleum pitch carbon quantum dots. The prepared petroleum pitch-based carbon quantum dot aqueous solution can be further subjected to rotary evaporation to remove most of the water, and then freeze-dried to obtain solid petroleum pitch-based carbon quantum dots.

[0039] Described petroleum pitch carbon quantum...

Embodiment 3

[0041] Weigh 2g of AH-70 asphalt at room temperature and put it into a 100ml flask, add 30ml of concentrated nitric acid and 60ml of concentrated sulfuric acid in turn, then put the flask into a 1000w ultrasonic cleaner for 2 hours to obtain a dispersion of petroleum asphalt; The above-mentioned petroleum asphalt dispersion was heated and refluxed in an oil bath at 100°C for 12 hours, cooled to room temperature, and adjusted to neutrality with NaOH and distilled water to obtain a crude product of carbon quantum dots; the obtained crude product was first filtered through a 0.22 μm microporous membrane After filtering, the filtered solution was dialyzed for 72 hours at room temperature in a dialysis bag with a molecular weight cut-off of 3500 Da to obtain an aqueous solution of petroleum pitch carbon quantum dots. The prepared petroleum pitch-based carbon quantum dot aqueous solution can be further subjected to rotary evaporation to remove most of the water, and then centrifugall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com