Method for preparing reduced graphene oxide heat conductive film

A heat-conducting film and graphene technology, applied in the field of carbon materials, can solve the problems of low graphene sheet orientation, many voids, and poor flexibility, and achieve the effect of easy industrial production, good flexibility, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

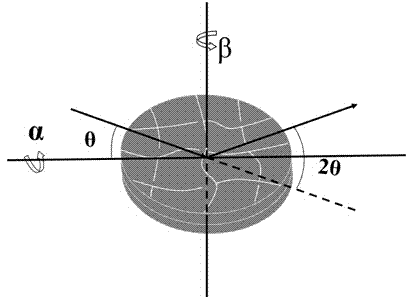

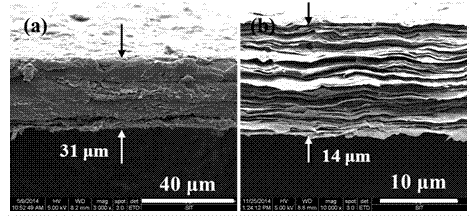

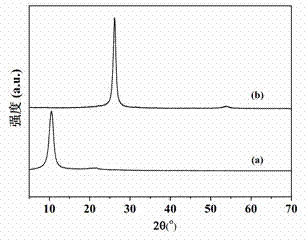

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a reduced graphene oxide heat conduction film, specifically comprising the steps of:

[0033] (1) Add graphite oxide to deionized water, sonicate at 80W, 40KHz for 10min, centrifuge the suspension obtained after sonication at 3000rpm for 5min, take the supernatant in a vacuum drying oven at 80°C for 24h, and then grind to obtain oxidized Graphene;

[0034] Graphite oxide and deionized water consumption, by graphite oxide: deionized water is the ratio calculation of 1g:500mL; Described graphite oxide is prepared by improved Hummers method;

[0035] (2) Add 400mg of the graphene oxide obtained in step (1) into 200mL of solvent, ultrasonicate at 100W, 40KHz for 1h, and obtain a graphene oxide dispersion with a concentration of 2mg / mL;

[0036] Described solvent is the mixed solution that deionized water and ethanol are 1:1 composition by volume ratio;

[0037](3) Vacuum filter 30 mL of the graphene oxide dispersion obtained in step (2) with a mixed...

Embodiment 2

[0046] A method for preparing a reduced graphene oxide heat conduction film, specifically comprising the steps of:

[0047] (1) Add graphite oxide into deionized water, sonicate for 30min (80W, 40KHz), centrifuge the suspension obtained after sonication at 2500rpm for 10min, take the supernatant and dry it in a vacuum drying oven at 80°C for 24h, then grind to obtain Graphene oxide;

[0048] Graphite oxide and deionized water consumption, by graphite oxide: deionized water is the ratio calculation of 1g:800mL; Described graphite oxide is prepared by improved Hummers method;

[0049] (2) Add 200mg of graphene oxide obtained in step (1) into 200mL of solvent, and ultrasonically treat it for 1h (100W, 40KHz) to obtain a dispersion of graphene oxide with a concentration of 1mg / mL;

[0050] Described solvent is the mixed solution that deionized water and ethanol are 1:1 composition by volume ratio;

[0051] (3) Vacuum filter 20 mL of the graphene oxide dispersion obtained in step...

Embodiment 3

[0055] A method for preparing a reduced graphene oxide heat conduction film, specifically comprising the steps of:

[0056] (1) Add graphite oxide to deionized water, ultrasonicate at 80W, 40KHz for 10min, centrifuge the suspension obtained after ultrasonication at 2000rpm for 20min, take the supernatant and dry it in a vacuum drying oven at 80°C for 24h, then grind to obtain oxidized Graphene;

[0057] The amount of graphite oxide and deionized water is calculated according to the ratio of graphite oxide: deionized water is 1g:1000mL; the graphite oxide is prepared by the improved Hummers method;

[0058] (2) Add 400mg of the graphene oxide obtained in step (1) into 200mL of solvent, ultrasonicate at 100W, 40KHz for 1h, and obtain a graphene oxide dispersion with a concentration of 2mg / mL;

[0059] Described solvent is the mixed solution that deionized water and ethanol are 1:1 composition by volume ratio;

[0060] (3) Vacuum filter 40 mL of the graphene oxide dispersion ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com